Bearing assembly disassembly tooling

An assembly and bearing technology, applied in the field of bearing assembly disassembly tooling, can solve problems such as adapter sleeve failure, difficulty in improving production efficiency, and low work efficiency, and achieve the effects of improving quality accuracy, eliminating potential safety hazards, and ensuring maintenance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

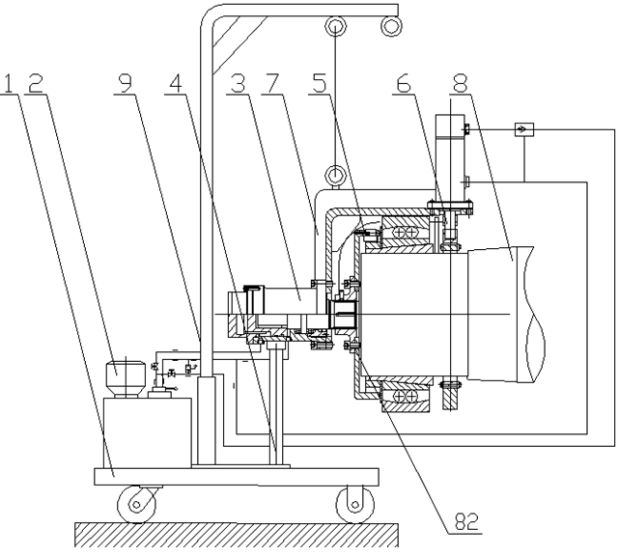

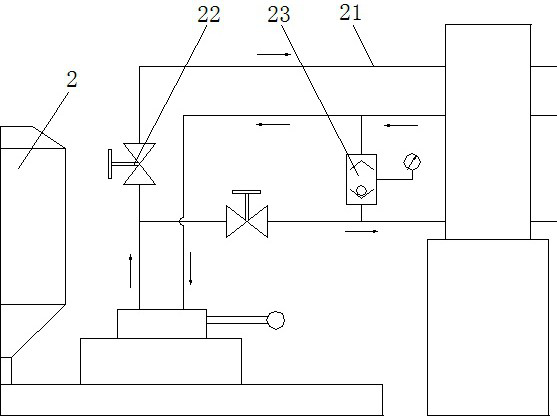

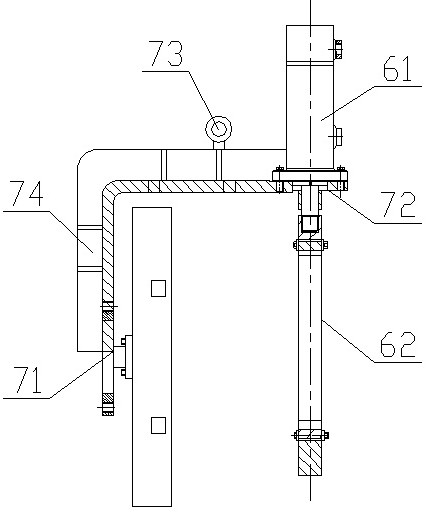

[0023] like figure 1 , a bearing assembly disassembly tooling, including a mobile platform 1, a power source 2, a driving device 3, a bracket assembly 4, a chuck connection assembly 5 and a journal clamping assembly 6, and the hydraulic station assembly 2 is fixedly mounted on a mobile On the platform 1, the driving device 3 is installed on the mobile platform 1 through the bracket assembly 4, the power source 2 is connected with the driving device 3, and the housing of the driving device 3 is fixedly equipped with a structural frame 7, and the The structural frame 7 is provided with a first positioning surface 71 and a second positioning surface 72, the chuck connection assembly 5 is installed on the first positioning surface 71, and the journal clamping assembly 6 is installed on the second positioning surface 72 , and when the journal clamping assembly 6 clamps the main shaft 81 of the bearing assembly 8, the axis of the chuck connection assembly 5 is parallel to the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com