Jaw crusher

A jaw crusher and jaw plate technology, which is applied in grain processing and other fields, can solve the problem of waste of manpower in jaw plate monitoring, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

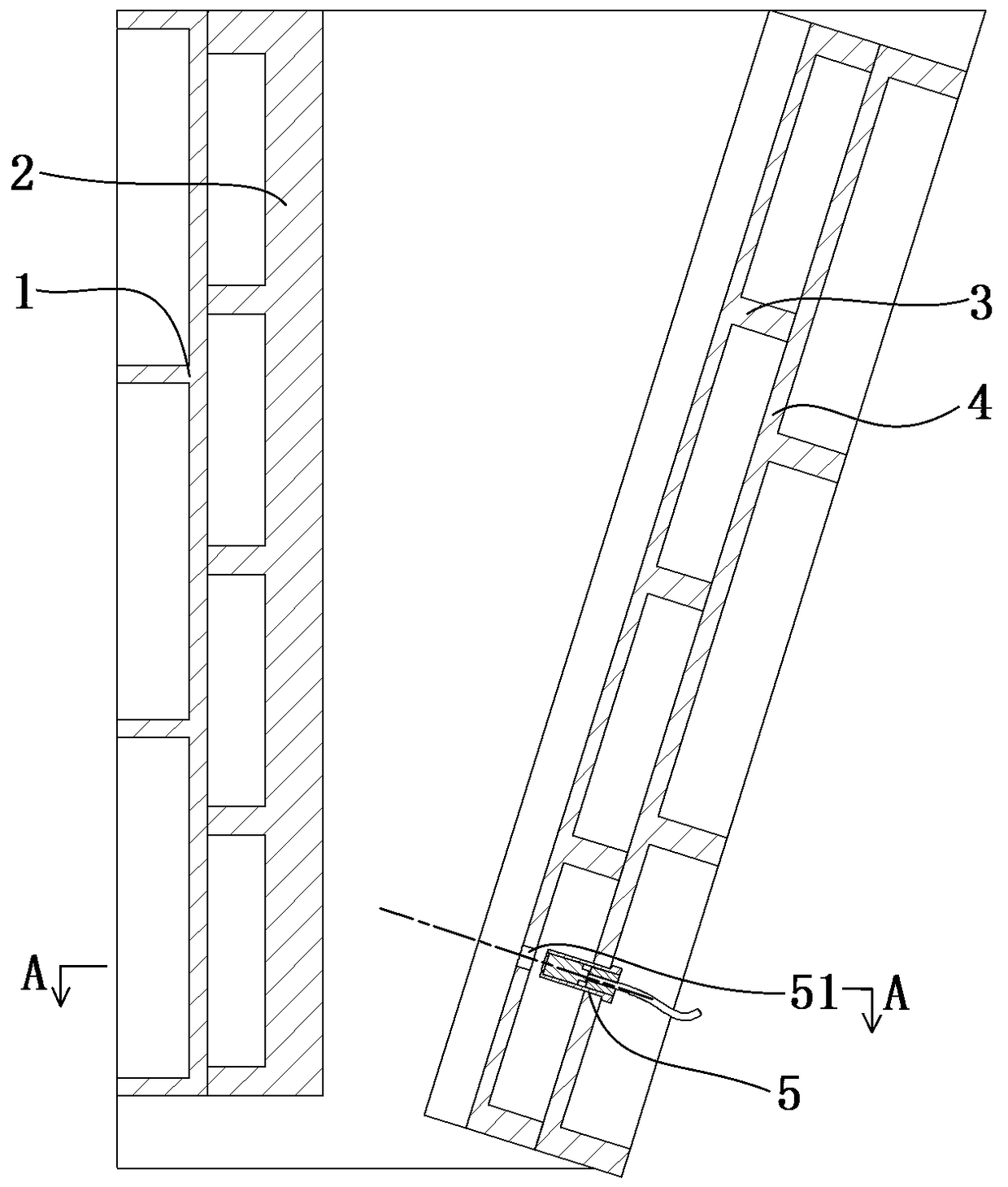

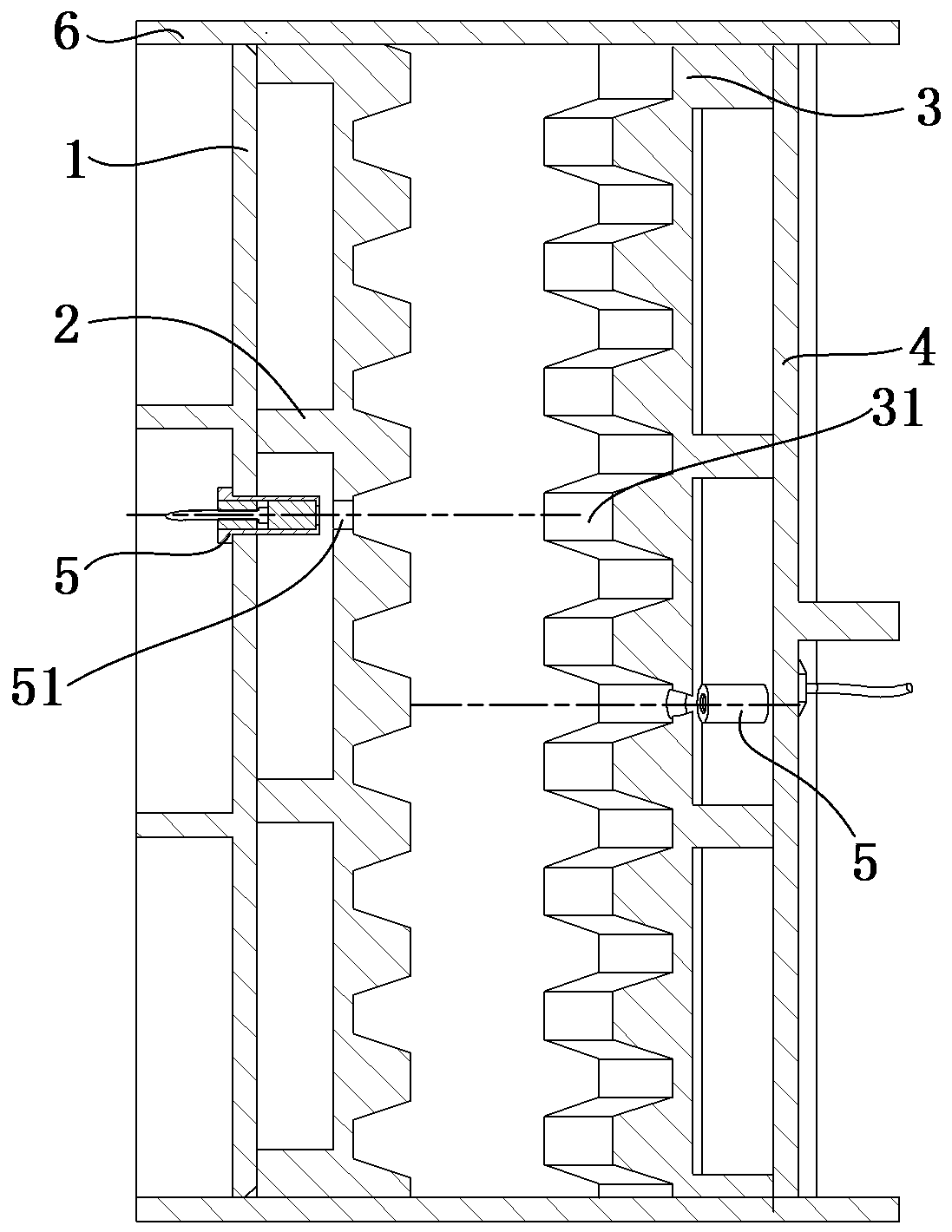

[0018] A specific embodiment of the jaw crusher of the present invention, such as Figure 1 to Figure 2 As shown, the jaw crusher includes a body on which a fixed jaw plate 1 is fixed, and a fixed jaw plate 2 is installed and fixed on the fixed jaw plate 1 . The lower end of the movable jaw plate fixed plate 4 is hingedly installed on the machine body, and the eccentric wheel drive mechanism of the movable jaw plate 3 is connected with the fixed plate through transmission. Driven by the mechanism, the fixed plate 4 of the movable jaw plate reciprocates around the hinge point at the lower end with the movable jaw plate. During the movement, the distance between the two jaw plates becomes larger and smaller periodically. When the material is filled in between, the material can be crushed into a material with a smaller particle size. The fixed jaw plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com