Low reflectivity 3D polarizing film, low reflectivity polarized LED and preparation method

A technology of low reflectivity and polarizing film, which is applied in the field of preparation of 3D polarizing film and polarized LED. It can solve the problems of low reflectivity 3D polarizing film polarized LED, large accumulative error of stitching, and poor product flatness, etc., so as to reduce crosstalk problems, make up for poor surface roughness, and achieve quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] It can be known from the above steps of the preparation method that the method of the present invention adopts the method of laminating the retardation film and the polarizing film to form a 3D polarizing film. Only one die-cutting is carried out, and the complex operations brought about by the traditional patchwork lamination are avoided through sheet lamination, which greatly improves the production and lamination efficiency;

[0067] At the same time, since there is no need to splice different polarizing films, at least half of the splicing error can be reduced.

[0068] Further, the present invention provides a method for preparing a low-reflectivity polarized LED, which method includes the steps and step seven of the method for preparing a low-reflectivity 3D polarizing film,

[0069] Step 7. Dispensing glue on the patterned AG anti-glare glass, polarizer or LED module of the 3D polarizing film, and aligning and bonding the 3D polarizing film and the LED module to ...

Embodiment 1

[0074] Please refer to Figure 1-6 As shown in the process, the preparation method of the 3D polarizing film provided in this embodiment is as follows:

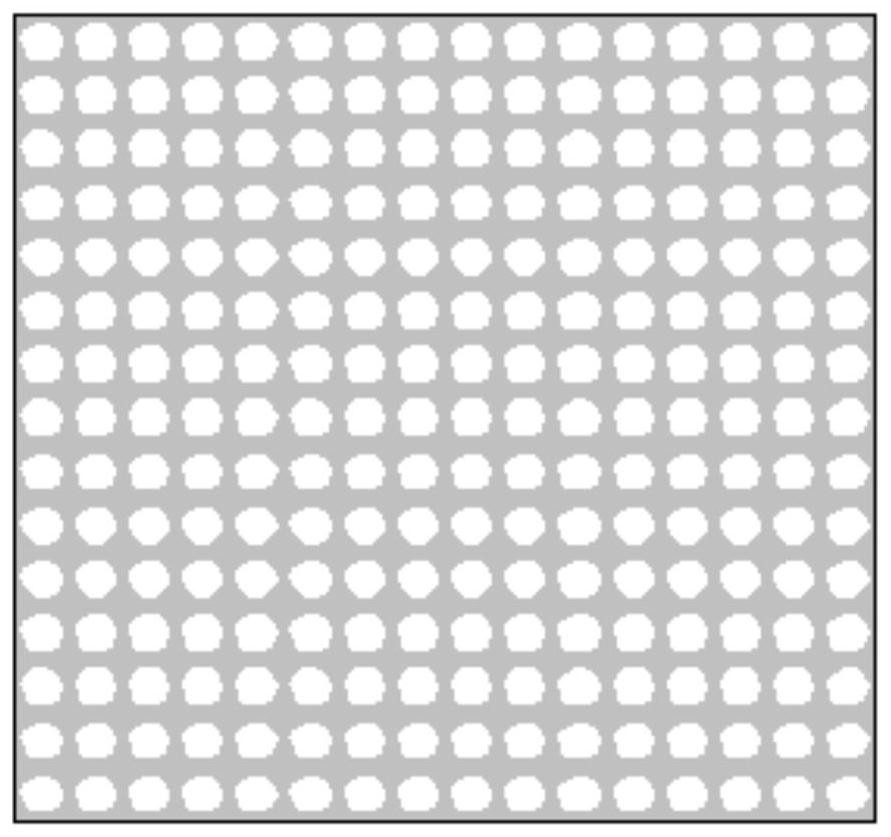

[0075] Step 1. Make a black light-shielding layer on the non-AG surface of the AG anti-glare glass, and then set an M×N through-hole array on the AG anti-glare glass to form a patterned AG anti-glare glass;

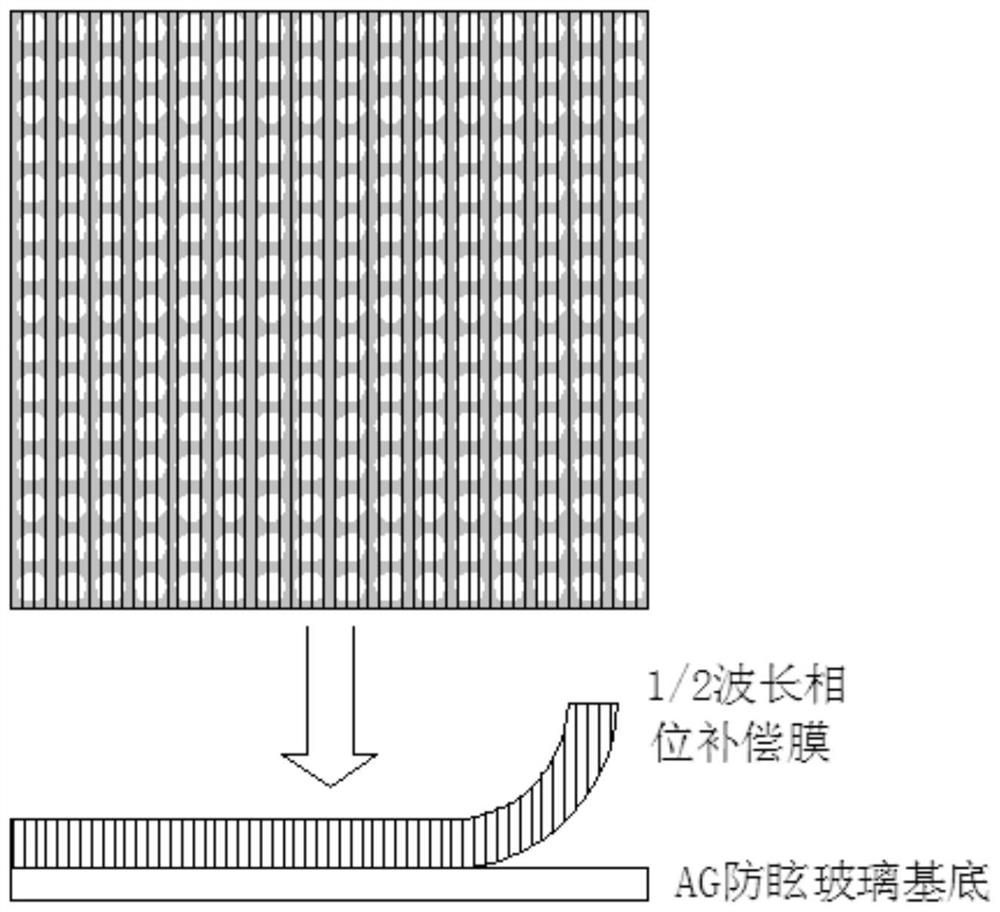

[0076] Step 2. The 1 / 2 wavelength phase difference compensation film is attached to the non-AG surface of the AG anti-glare glass layer, that is, the black light-shielding layer;

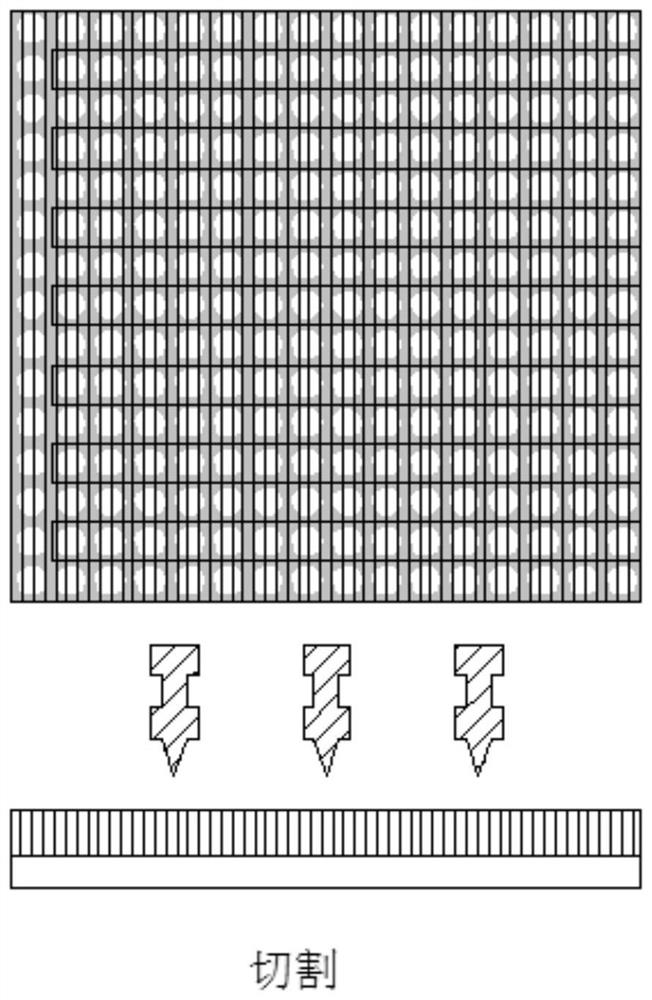

[0077] Step 3. Cutting the 1 / 2 wavelength retardation compensation film attached to the AG anti-glare glass layer to form a patterned structure;

[0078] Step 4, peeling off the invalid area in the obtained patterned structure;

[0079] Step 5, filling the surface of the stripped patterned structure to form a planarization layer;

[0080] Step 6: The polarizer and the planarization layer are laminated in alignment to obtain the 3D polarizin...

Embodiment 2

[0082] Please refer to Figure 1-6 As shown in the process, the preparation method of the 3D polarizing film provided in this embodiment is as follows:

[0083] Step 1. Make a black light-shielding layer on the non-AG surface of the AG anti-glare glass, and then set an M×N through-hole array on the AG anti-glare glass to form a patterned AG anti-glare glass;

[0084] Step 2. The 1 / 2 wavelength phase difference compensation film is attached to the non-AG surface of the AG anti-glare glass layer, that is, the black light-shielding layer;

[0085] Step 3. Cutting the 1 / 2 wavelength retardation compensation film attached to the AG anti-glare glass layer to form a patterned structure;

[0086] Step 4, peeling off the invalid area in the obtained patterned structure;

[0087] Step 5, filling the surface of the stripped patterned structure to form a planarization layer;

[0088] Step 6: The polarizer and the black light-shielding layer of the AG anti-glare glass are aligned and bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com