Orientated detection device for density of solution

A detection device and solution technology, applied in the direction of material analysis by measuring buoyancy, can solve the problems of unfavorable quality control, waste of resources, and high sampling frequency, achieve automatic and continuous production, avoid production interruption, and reduce false triggers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

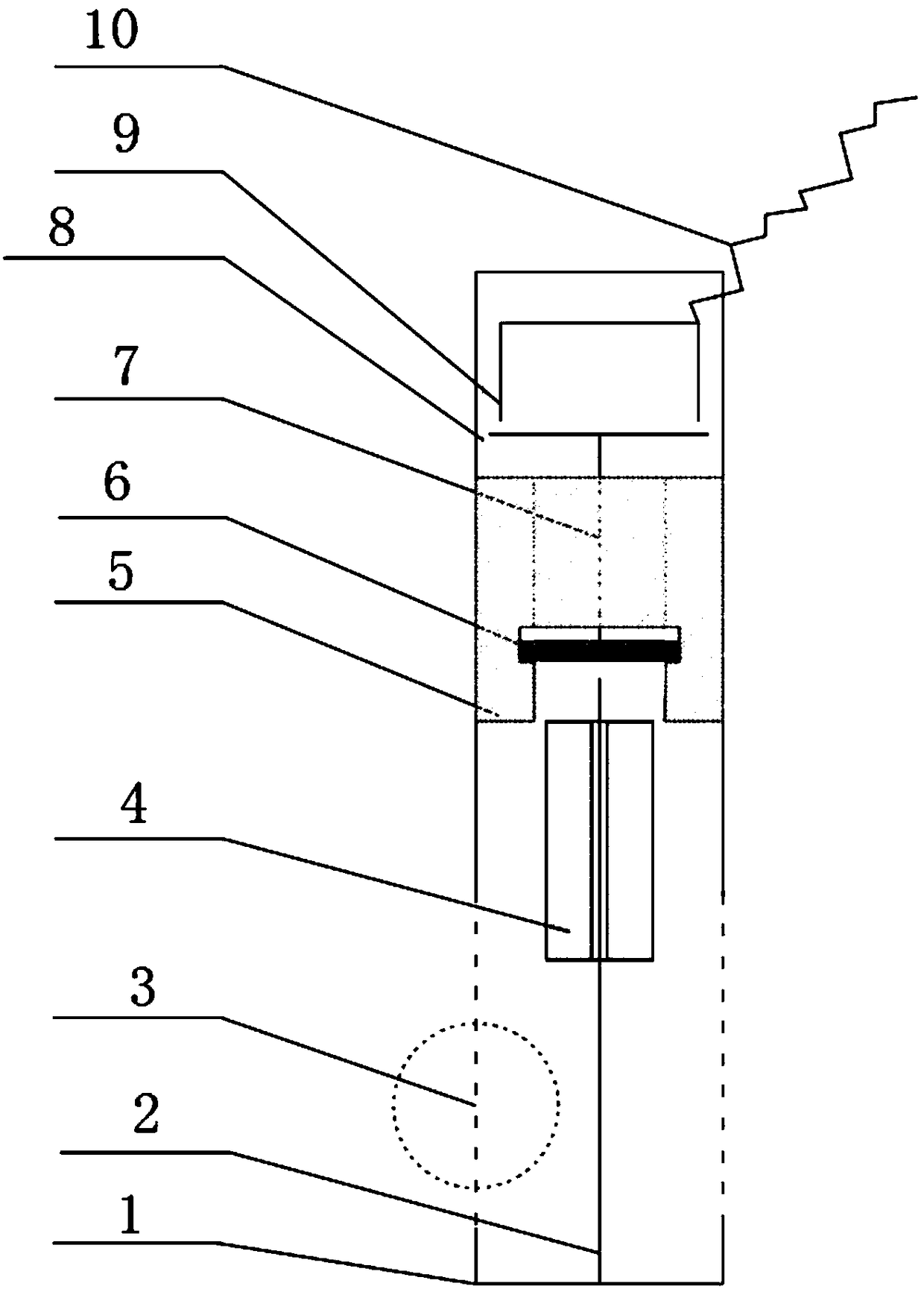

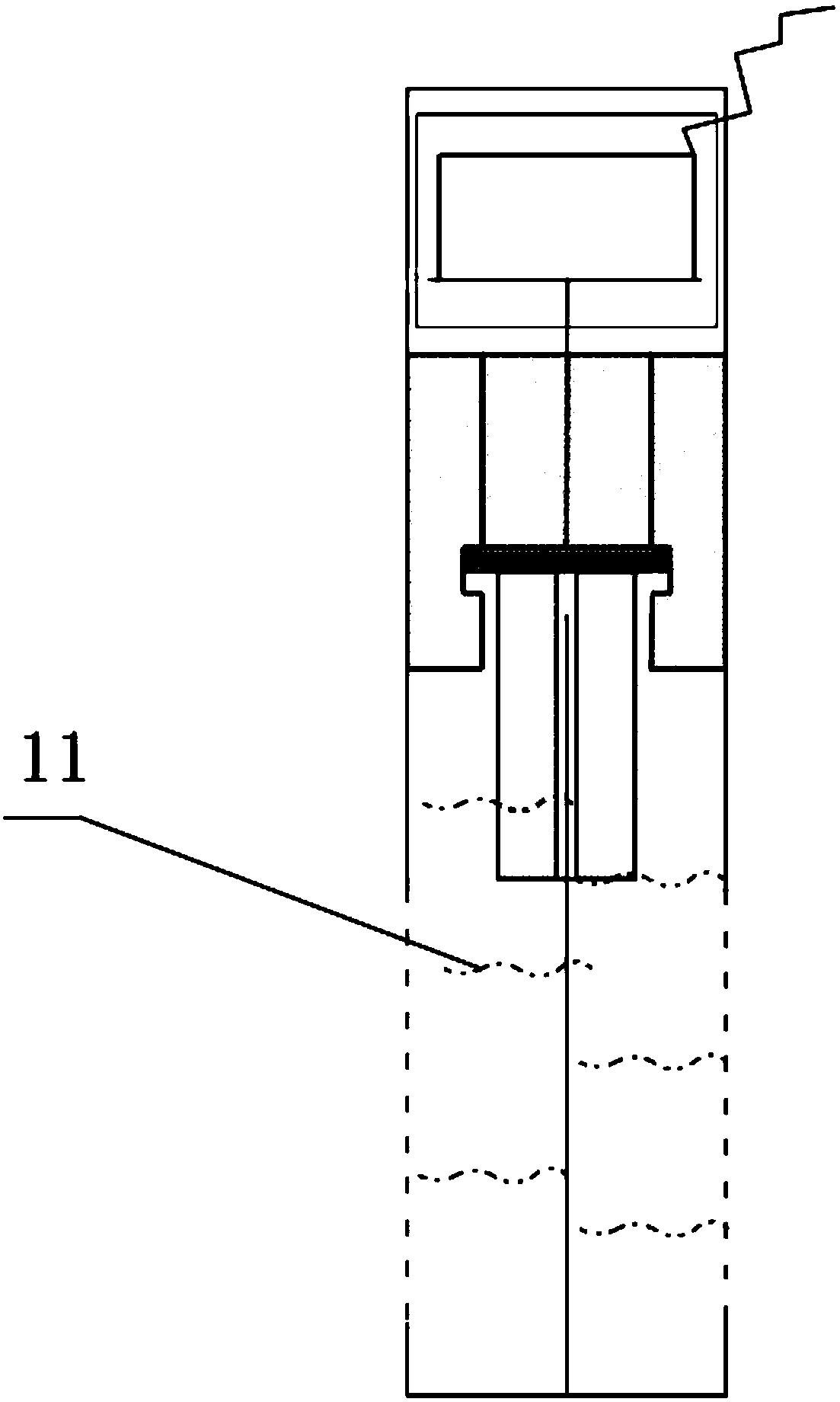

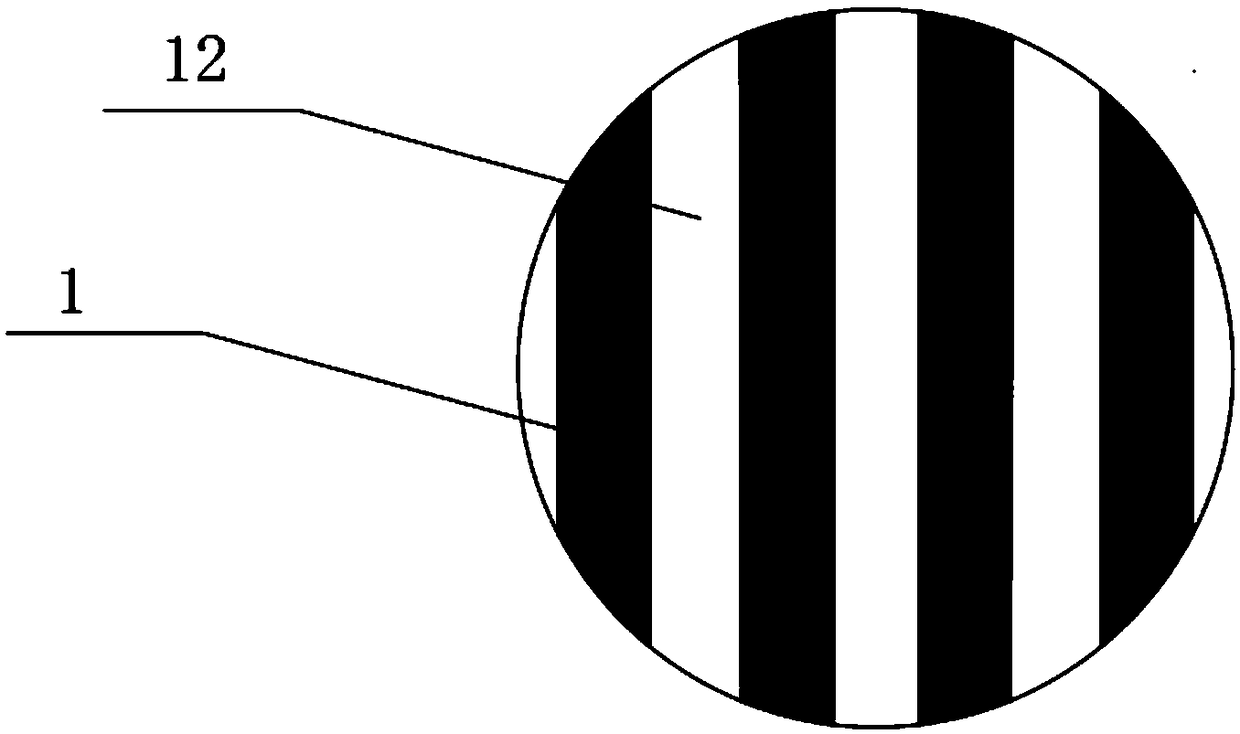

[0029] like Figure 1 to Figure 5 As shown, a solution density orientation detection device includes a floating ball 4 that can move along the guide rod 2, the floating ball 4 is placed in the cavity in the shell 1, and is arranged in sequence in the shell 1 away from the end of the guide rod 2 There are a signal trigger 6 and a signal contactor 9, and the signal contactor 9 is connected to the interface of the control system through a wire 10. The side surface 3 of the casing 1 is provided with a solution inlet and outlet 12 communicating with the cavity. The solution inlet and outlet 12 are a plurality of square slots parallel to the guide rod 2 and distributed on the side surface of the casing 1 at equal intervals. One end of the guide rod 2 is fixedly connected to the casing 1, and the other end is a free end. The floating ball 4 is a cylinder 14 with a guiding channel 13 along its own axis. The cylinder 14 includes an annular vacuum chamber 15 positioned on the outside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com