Paver and loader for same

A technology of road pavers and loaders, which is applied in the direction of roads, roads, road repairs, etc., and can solve the problems of a large number of additional costs for personnel and machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

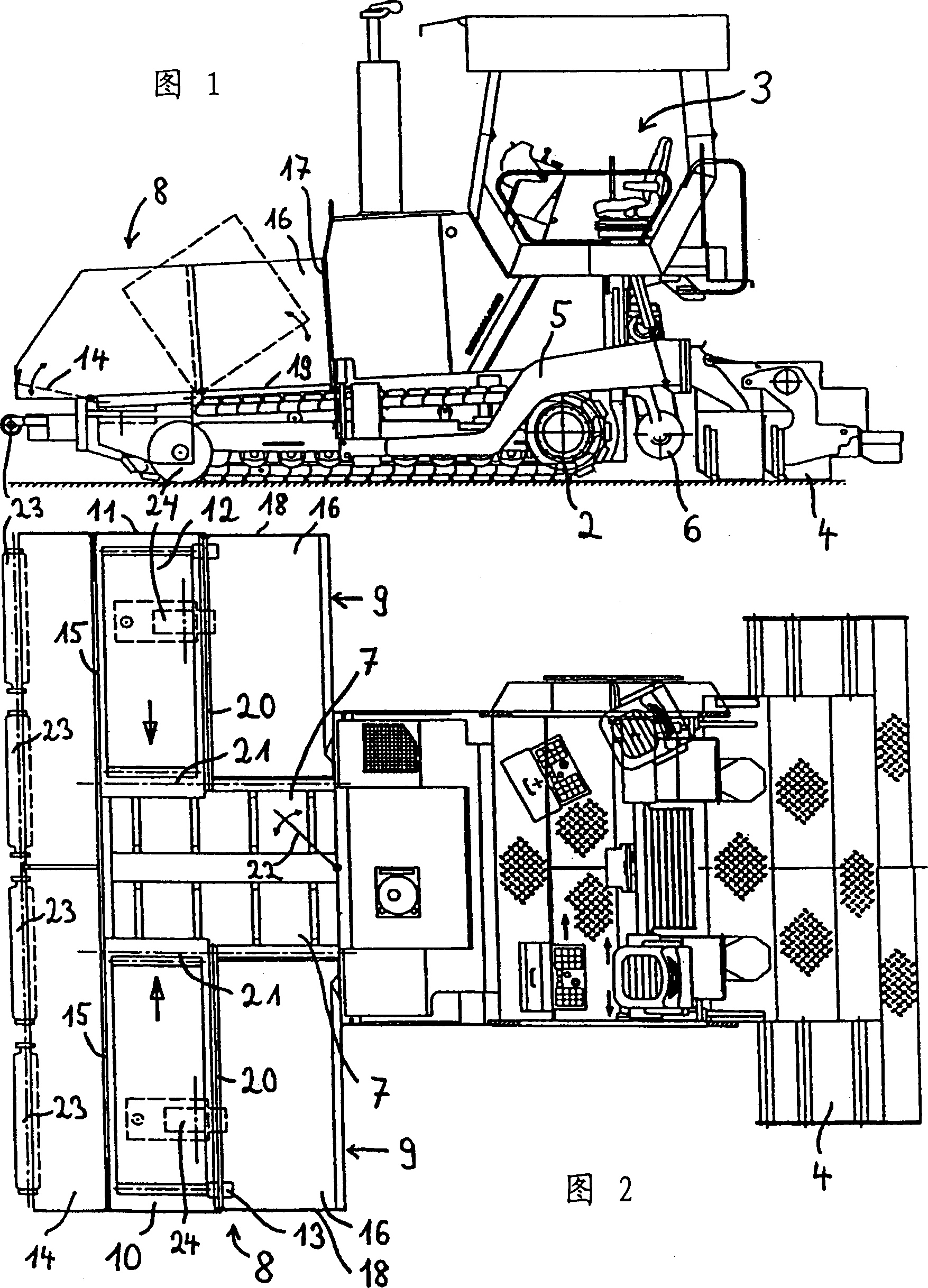

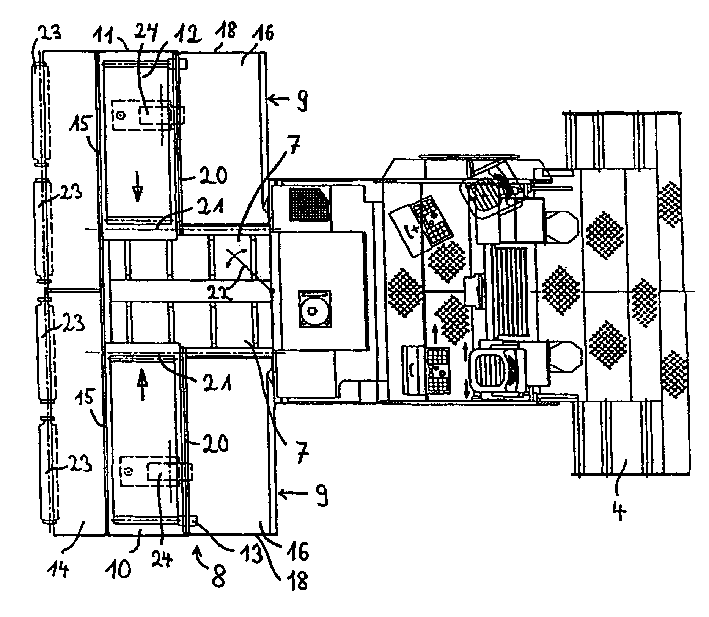

[0016] The illustrated paving machine comprises a chassis 1 on which is provided a guideable traveling drive train 2 , a driver's cab 3 and a screed 4 . Travel drive train 2 with wheels and / or travel drive chain; drives the paving machine from the driver's cab; along the laying direction on the rear side there is a screed 4, which is articulated to the chassis 1 via tension arms 5 and can float on the paving material .

[0017] Located in front of the screed 4 is an auger distributor 6 for the paving material. The paving material is supplied to the auger distributor 6 via the longitudinal conveying device 7 . A longitudinal conveying device 7 is centrally arranged on the chassis 1 and extends under the driver's cab 3 , preferably comprising two parallel conveyors and opening into a hopper 8 located at the front in the laying direction.

[0018] The hopper 8 comprises two half-hoppers 9 each having a bottom 8a and a substantially vertical side wall 8b. The hopper 8 opens dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com