Heat performance test system

A technology for testing system and thermal performance, which is applied in the testing of machines/structural components, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

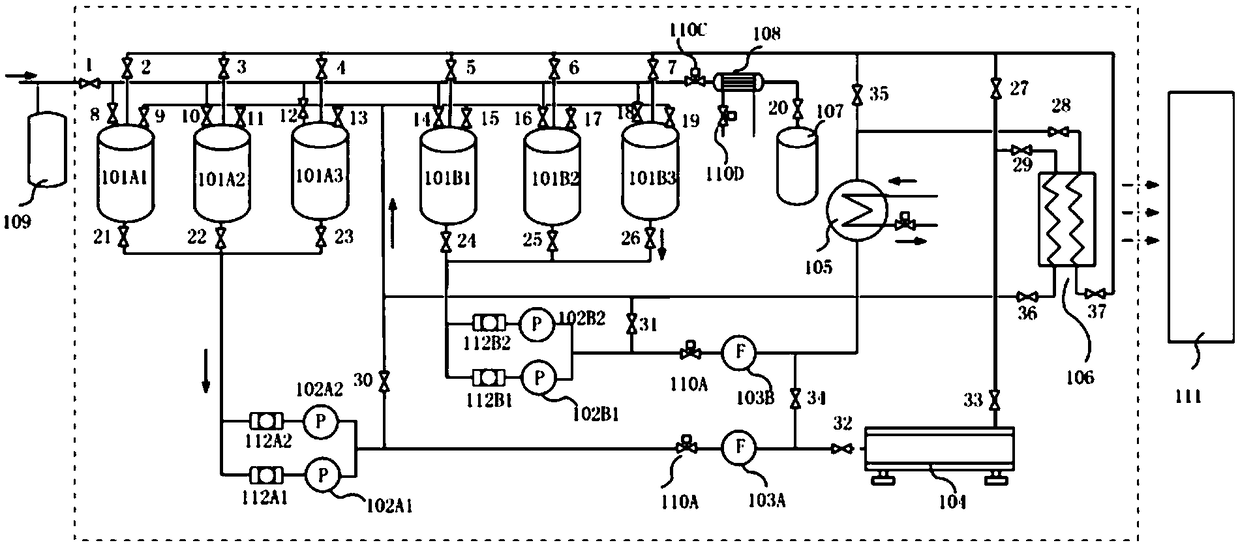

[0056] like figure 1 Shown is Embodiment 1 of the thermal performance testing system of the present invention. This embodiment is mainly used to test the heat storage performance of the heat storage device. This system includes a measurement and control unit 111, a heat generation and storage unit, a voltage stabilization unit, and a waiting Measure heat storage device 106.

[0057] Thermal energy generation and storage unit, including high temperature storage tank 101A, low temperature storage tank 101B, filters 112A, 112B, pumps 102A, 102B, electric heater 104, cooler 105, flow control components (including flow meters 103A, 103B, flow control valves 110A, 110B). Among them, valves 2, 3, and 8 are respectively provided at the first liquid inlet, the second liquid inlet, and the bottom liquid outlet of the top of the high-temperature storage tank 101A; the first liquid inlet at the top of the low-temperature storage tank 101B Valves 5, 4, 10 are respectively provided at the...

Embodiment 2

[0070] like figure 2 As shown, the difference from Example 1 is that this example is mainly used to test the heat exchange performance of the heat exchange device. The liquid discharge port of the heat exchange device 106 to be tested is connected to a high-temperature liquid discharge line and a low-temperature liquid discharge line, and both the high-temperature liquid discharge line and the low-temperature liquid discharge line are connected to the liquid inlets of the high-temperature storage tank 101A and the low-temperature storage tank 101B; When testing the heat exchange performance of the heat exchange device 106 to be tested, the low-temperature heat transfer fluid in the cryogenic storage tank 101B flows into the cold side of the heat exchange device 106 to be tested through the cooler 105 through the low-temperature liquid inlet pipeline driven by the cryopump 102B, And flow out into the low-temperature storage tank 101B through the high-temperature drain line of ...

Embodiment 3

[0072] like image 3 Shown is Embodiment 3 of the high-temperature heat storage performance testing system of the present invention. This system is mainly composed of four parts: measurement and control unit 111, thermal energy generation and storage unit, pressure maintenance unit, and heat exchanger 106 of the device under test test system. The thermal energy generation and storage unit includes three parallel high-temperature storage tanks 101A1, 101A2, 101A3, three parallel low-temperature storage tanks 101B1, 101B2, 101B3, four filters 112A1, 112A2, 112B1, 112B2, four pumps 102A1, 102A2, 102B1, 102B2, one electric heater 104, one cooler 105, two high-temperature resistant flowmeters 103A, 103B; the pressure maintenance unit includes a buffer tank 109, a condenser 108, and a liquid collection tank 107; the device under test is the liquid / liquid heat exchanger 106 . The main working principle of the packed bed 106 is to complete energy exchange between two different liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com