A fast response and high precision total temperature thermocouple head structure

A fast-response, high-precision technology, applied in thermometers, measuring heat, using electrical devices, etc., can solve the problems of reduced reliability of thermocouples, easy failure of even wires, and increased temperature measurement time constants of thermocouples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

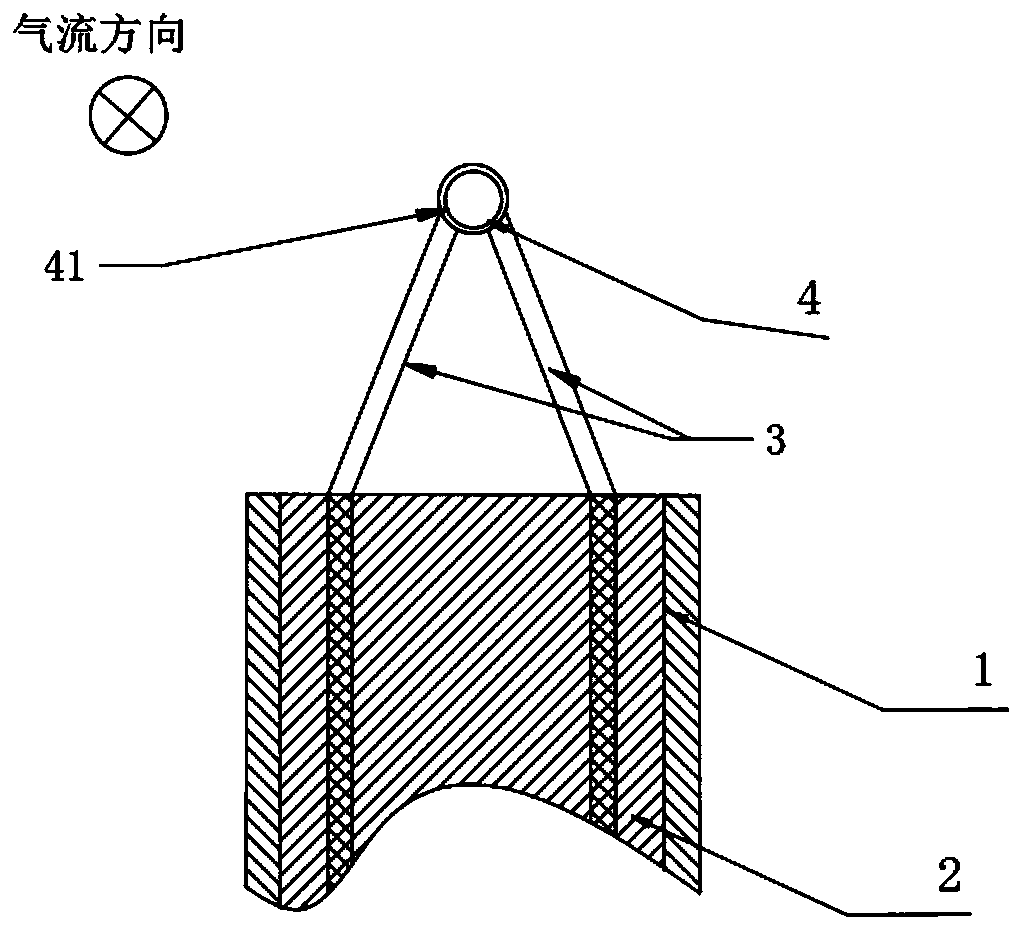

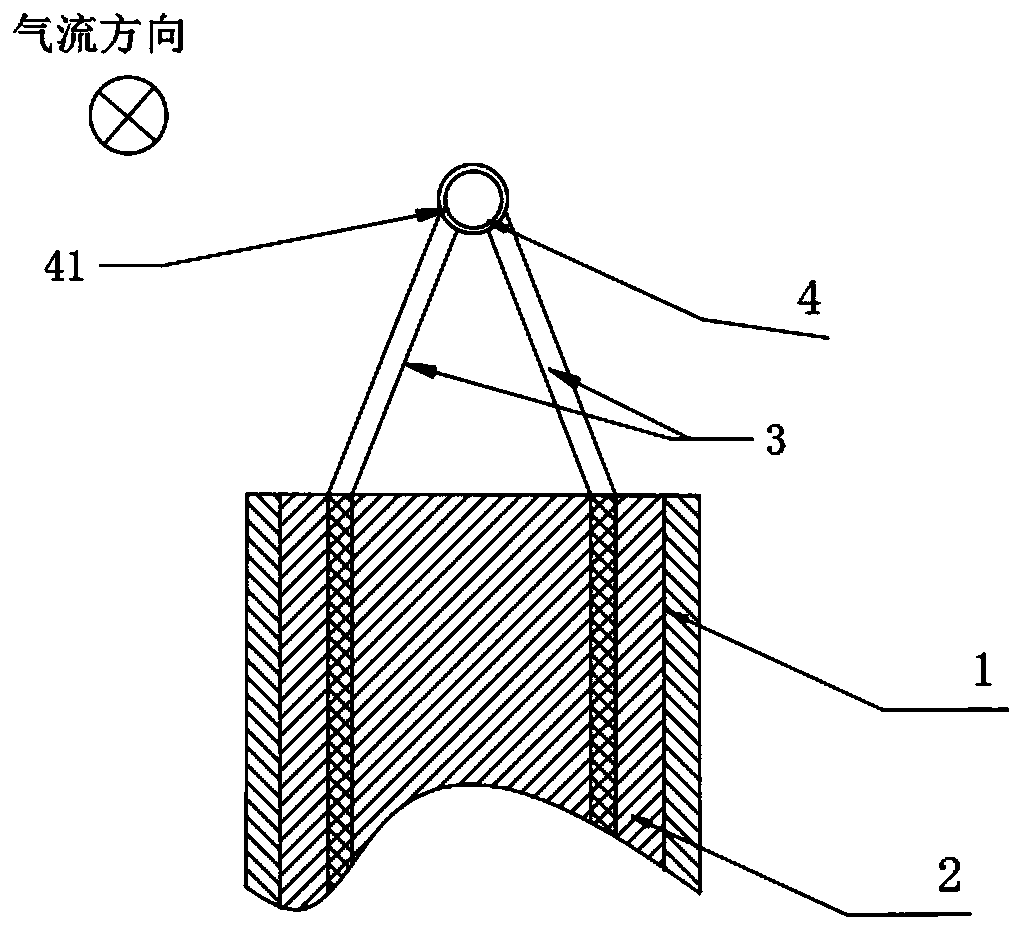

[0025] figure 1 , figure 2 It is a structural schematic diagram of Embodiment 1 of the present invention. As shown in the figure, a fast-response high-precision total temperature thermocouple head structure is characterized in that it includes a protective sleeve (1), an insulating layer (2), two galvanic wires (3) of different materials, The dual wire contact (4), the windward side of the dual wire contact (4) is an airflow stagnation structure (41) including a plane. The distance between the plane of the plane stagnation structure (41) on the windward side and the center of the sphere of the couple wire contact (4) is 1 / 2 times the radius of the couple wire contact (4).

Embodiment 2

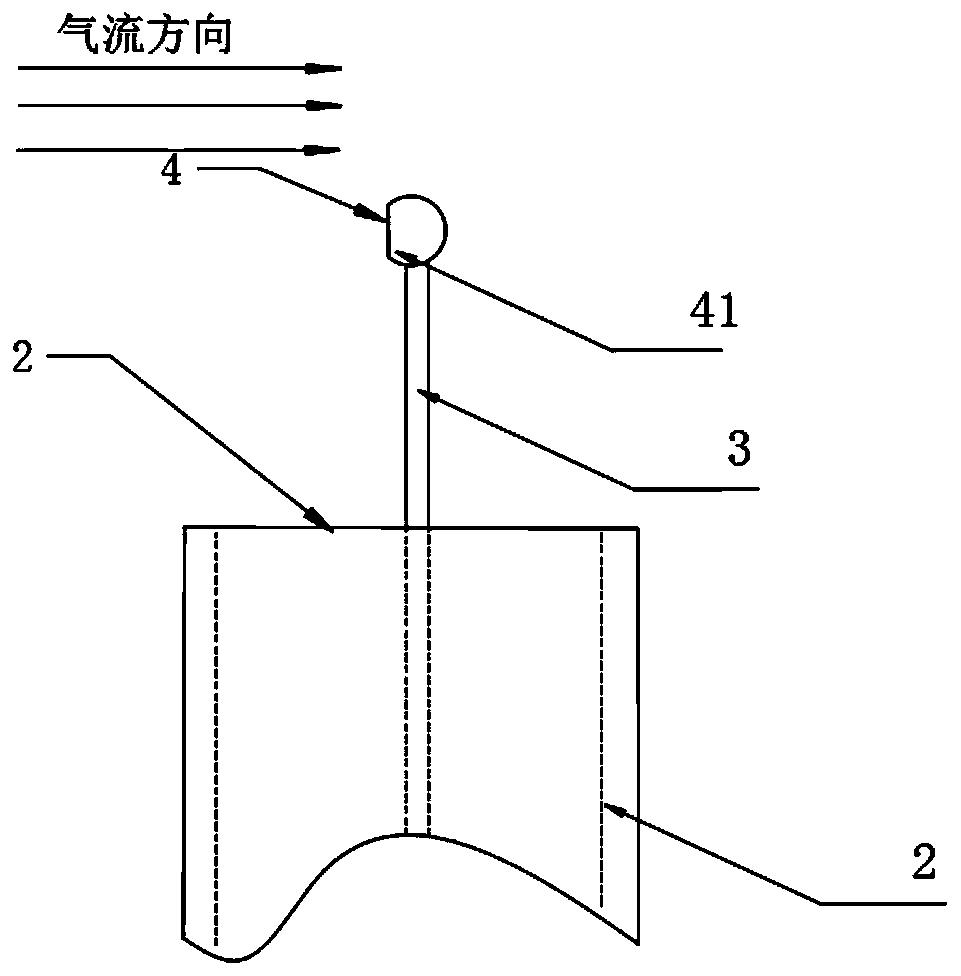

[0027] image 3 , Figure 4 It is a structural schematic diagram of Embodiment 2 of the present invention. As shown in the figure, a fast-response high-precision total temperature thermocouple head structure is characterized in that it includes a protective sleeve (1), an insulating layer (2), two galvanic wires (3) of different materials, The dual wire contact (4), the windward side of the dual wire contact (4) includes a concave hemispherical airflow stagnation structure (41).

[0028] In the described concave hemispherical surface stagnation structure (41), the radius of the concave hemisphere is 2 / 3 times the radius of the dual wire contact (4), and the center of the concave hemispherical surface is 2 from the center of the dual wire contact (4). / 3 times the radius of the even wire contact (4).

Embodiment 3

[0030] Figure 5 , Image 6 It is a structural schematic diagram of Embodiment 3 of the present invention. As shown in the figure, a fast-response high-precision total temperature thermocouple head structure is characterized in that it includes a protective sleeve (1), an insulating layer (2), two galvanic wires (3) of different materials, The dual wire contact (4), the windward side of the dual wire contact (4) includes a concave conical airflow stagnation structure (41).

[0031] The radius of the bottom surface of the cone surface airflow stagnation structure (41) is 2 / 3 times the radius of the dual wire contact (4), and the height of the cone surface is 2 / 3 times the radius of the dual wire contact (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com