Jacket valve with heat insulation function

A jacket and valve technology, applied in valve details, valve device, valve heating/cooling device, etc., can solve the problem of premature condensation inside the valve body, and achieve the effect of avoiding premature condensation, uniform heating and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

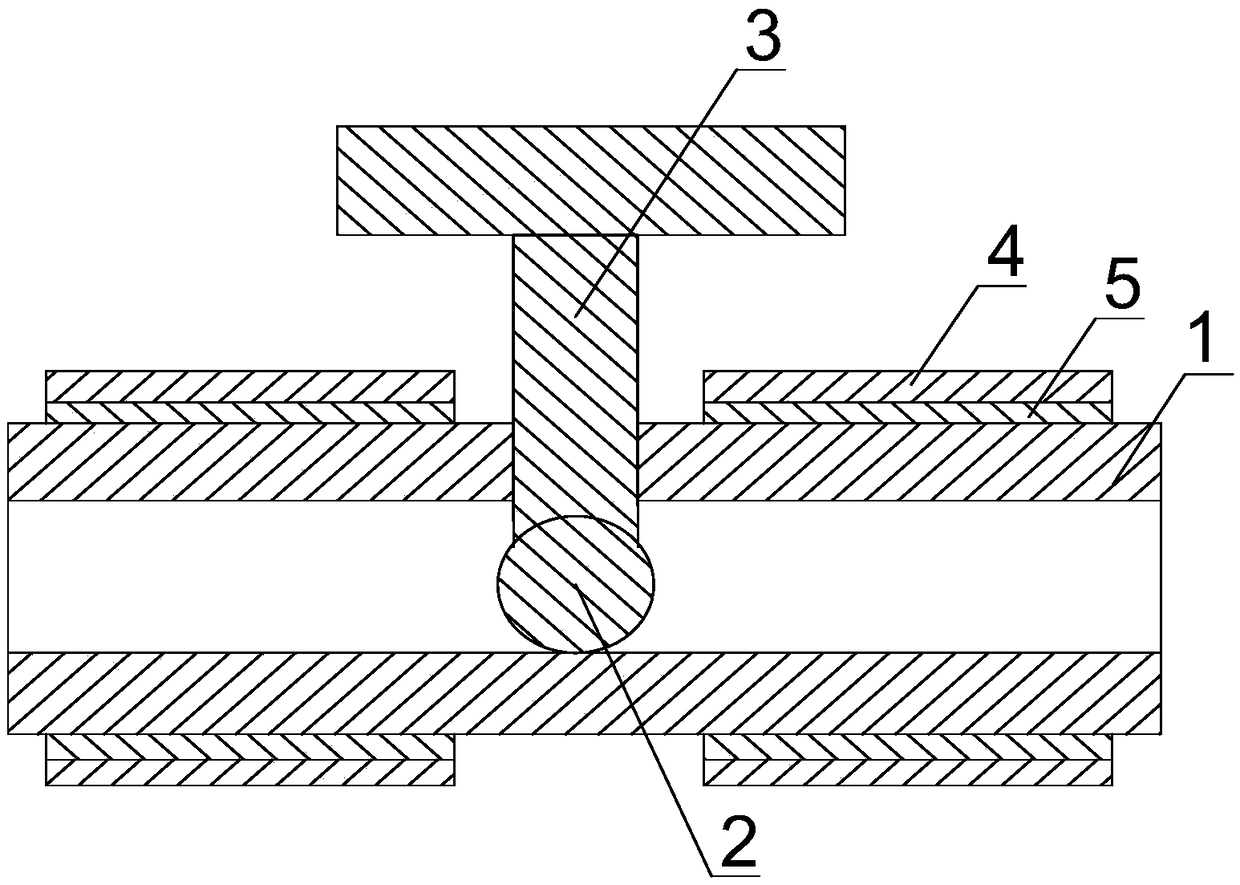

[0023] Such as figure 1 As shown, the jacketed valve with heat preservation function of the present invention includes a straight-through valve body 1, a valve core 2 installed inside the valve body 1, a valve stem 3 connected to the valve core 2, the valve stem 3 is located above the valve body 1 and Perpendicular to the valve body 1, the outer wall of the valve body 1 on both sides of the valve stem 3 is covered with a heating jacket 4 coaxial with the valve body 1, and an annular heat storage body 5 is installed between the heating jacket 4 and the outer wall of the valve body 1. The annular heat storage body 5 is coaxial with the valve body 1 , the inner wall of the annular heat storage body 5 is closely connected with the outer wall of the valve body 1 , and the outer wall of the annular heat storage body 5 is closely connected with the inner wall of the heating jacket 4 . The annular heat storage body 5 is a honeycomb ceramic annular heat storage body. The heating jacke...

Embodiment 2

[0026] Based on Embodiment 1, a temperature sensor is inserted between the annular regenerator 5 on both sides of the valve stem 3 and the corresponding outer wall of the valve body 1, and the temperature sensing head of the temperature sensor is moved from the valve body 1 along the axial direction of the valve body 1. One end is inserted between the annular heat storage body 5 and the corresponding outer wall of the valve body 1, and the temperature sensing head of the temperature sensor is a flat temperature sensing head.

[0027] The temperature sensor is used to detect the temperature between the valve body and the annular heat storage body, monitor the heating temperature of the valve body, and avoid the valve body being in a high temperature state for a long time. It is unsafe to use the valve body in a high temperature state for a long time and will reduce its service life. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com