Electro-hydraulic executer capable of preventing fire loss increment

An electro-hydraulic actuator and hydraulic technology, applied in the direction of valve operation/release devices, valve details, safety valves, etc., can solve problems such as fire damage expansion, electro-hydraulic actuators cannot work, valves cannot be closed, etc., to avoid Effect of Fire Loss Expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

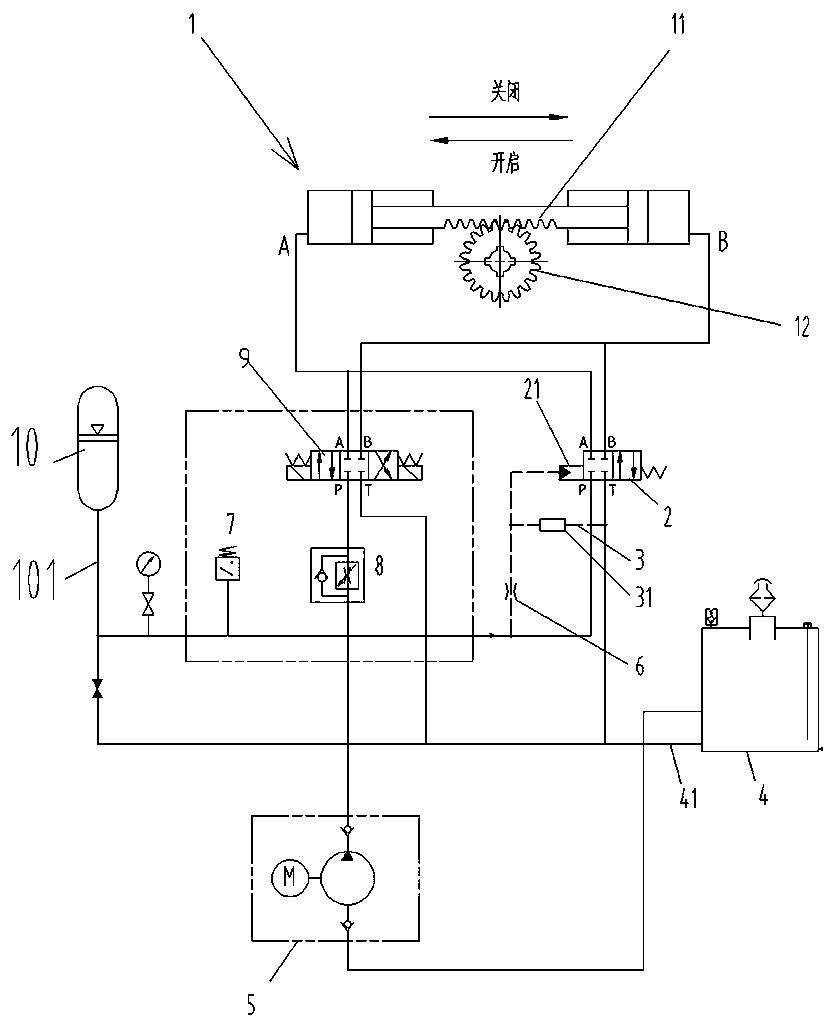

[0010] Set the rotary cylinder 1 to drive the valve to close, and the moving direction of the rack is that the rack moves from cylinder A to cylinder B. The present invention includes a rotary oil cylinder, an oil tank 4 and its oil return pipeline 41, an accumulator 10 and its oil pipe 101, the rotary oil cylinder includes two oil cylinders A and B, one end of the fusible plug pipeline 3 and the control of the hydraulic reversing valve 2 The cavities 21 are all connected to the oil pipe 101 of the accumulator, and the other end of the fusible plug pipe is connected to the oil return pipe 41 of the oil tank. When the rotary cylinder drives the valve to close, the hydraulic reversing valve and the electromagnetic reversing valve 9 are connected in parallel, that is, two A port, B port, P port and T port of the valve are connected together. One-way throttle valve 8 regulates the movement speed of the actuator, 7 is a pressure switch, and 6 is a throttle valve.

[0011] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com