Multi-parameter-based large and medium-scaled low lift vertical-type water pump set state evaluating method

A low-lift vertical, unit status technology, applied in the direction of non-variable pumps, pump control, mechanical equipment, etc., can solve the problems of harsh working environment, high labor cost, small monitoring range, etc., to overcome the small monitoring range, Save labor costs and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

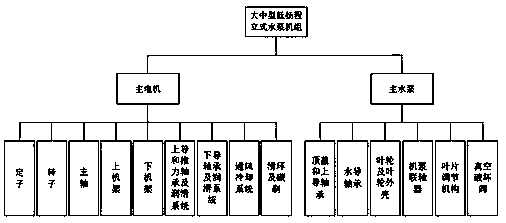

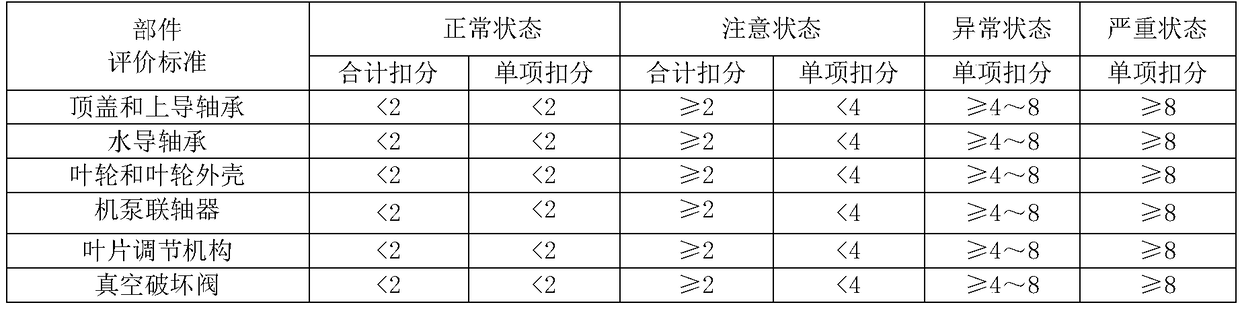

[0064] Such as figure 1 As shown, the components are firstly divided and the evaluation state quantities are determined. The large and medium-sized vertical water pump units are decomposed into two main equipments: the main motor and the main water pump. The main motor is divided into 9 parts including stator, rotor, main shaft, upper frame, lower frame, upper guide and thrust bearing and lubrication system, lower guide and lubrication system, ventilation and cooling, slip ring and carbon brush. The main water pump is divided into six parts: the top cover and the upper guide bearing, the water guide bearing, the impeller and the impeller casing, the pump coupling, the blade adjustment mechanism, and the vacuum breaker valve.

[0065] Each component is evaluated by several state quantities that reflect the state of the component. These state quantities spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com