Slag discharge device of quick replacement type zinc liquid pump

A zinc liquid and bottom plate technology, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve the problem of not being able to observe the liquid level of the zinc liquid pump and the state of zinc sticking, and the impossibility of realizing the zinc liquid pump On-line replacement, long on-site maintenance time and other problems, to achieve the effect of improving maintenance efficiency, simple structure, reducing manufacturing cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

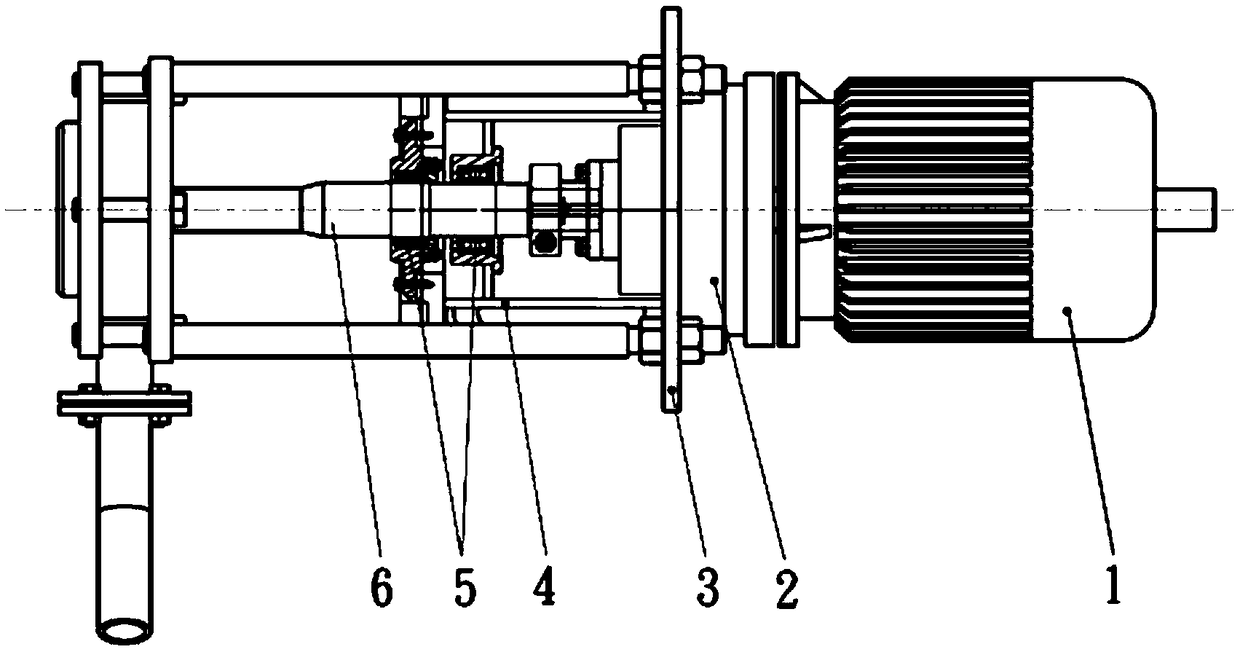

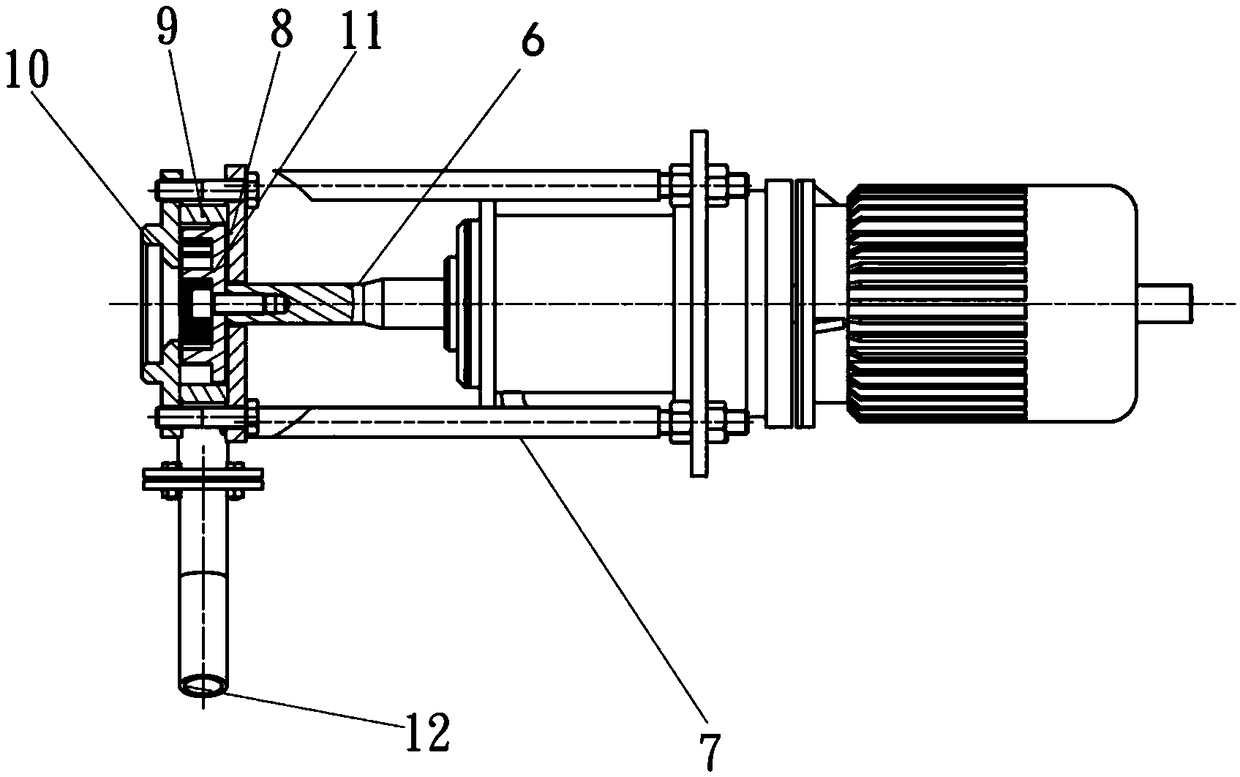

[0018] Such as figure 1 figure 2 and image 3 As shown, the present embodiment includes a top plate 8, a bottom plate 10, a surrounding pipe 9, a draft pipe 12, a stud 7, a spiral blade 11 and a power part; the head end of the stud 7 is connected to the power part , the ends are connected to the top plate 8 and the bottom plate 10 in turn, the surrounding tube 9 is surrounded and arranged between the top plate 8 and the bottom plate 10, the surrounding tube 9 communicates with the guide tube 12 for draining, the top plate 8, the bottom plate 10, The surrounding pipe 9 and the guide tube 12 form a cavity for pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com