Hackling slivering machine control device and control method

A technology of a control device and a control method, applied in combing machines, mechanical processing, textiles and papermaking, etc., can solve problems such as increasing production costs, affecting fiber quality, reducing sliver unevenness, etc., and achieving the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments of the specification.

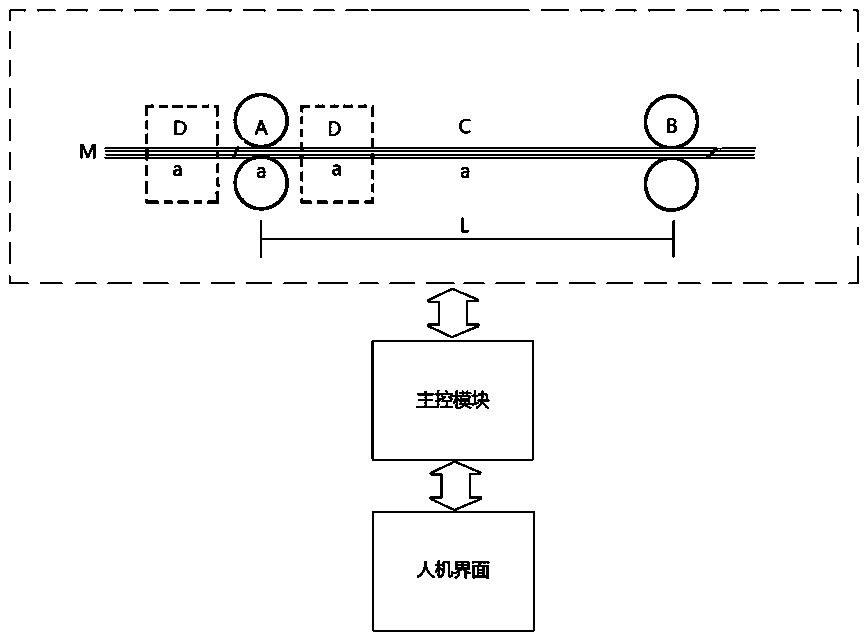

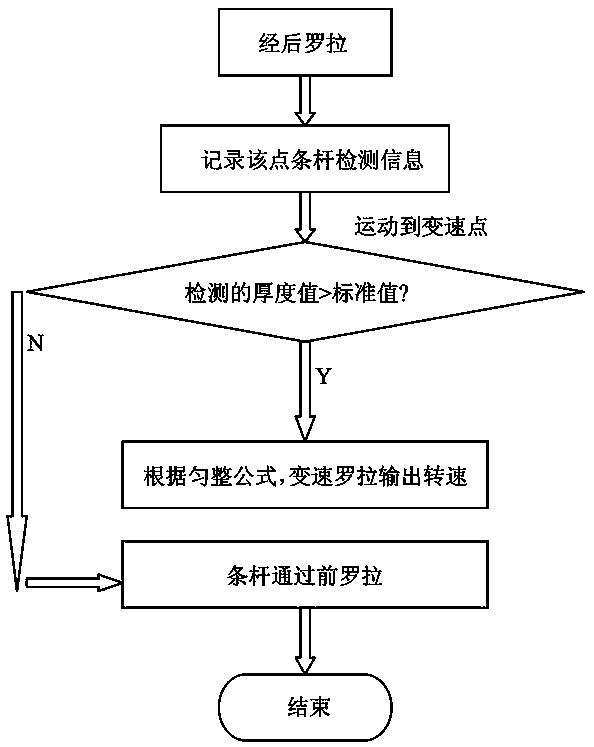

[0026] Such as figure 1 As shown, the control device of the combing sliver machine of this embodiment includes a control unit ( figure 1 Main control module in the bar), along the conveying direction of the bar ( figure 1 From left to right in the middle), the rear drafting unit A and the front drafting unit B (specifically the drafting roller) are arranged in sequence, and the rear drafting unit and the front drafting unit cooperate with each other to draft to realize the conveying of the bar M ; The position C (detection point) between the rear drafting unit and the front drafting unit is provided with a bar thickness detection part for real-time detection of the thickness of the bar; the control unit is respectively connected with the bar thickness detection part and the back draft The drawing unit is connected with the front drafting un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com