Low-temperature-freezing recycling treatment method for cadmium telluride thin-film solar cell

A solar cell, low temperature freezing technology, applied in the directions of binary selenium/tellurium compound, selenium/tellurium oxide/hydroxide, improvement of process efficiency, etc. problems such as small size, poor working environment, etc., to achieve the effect of high comprehensive utilization rate, environmental friendliness of the whole process, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

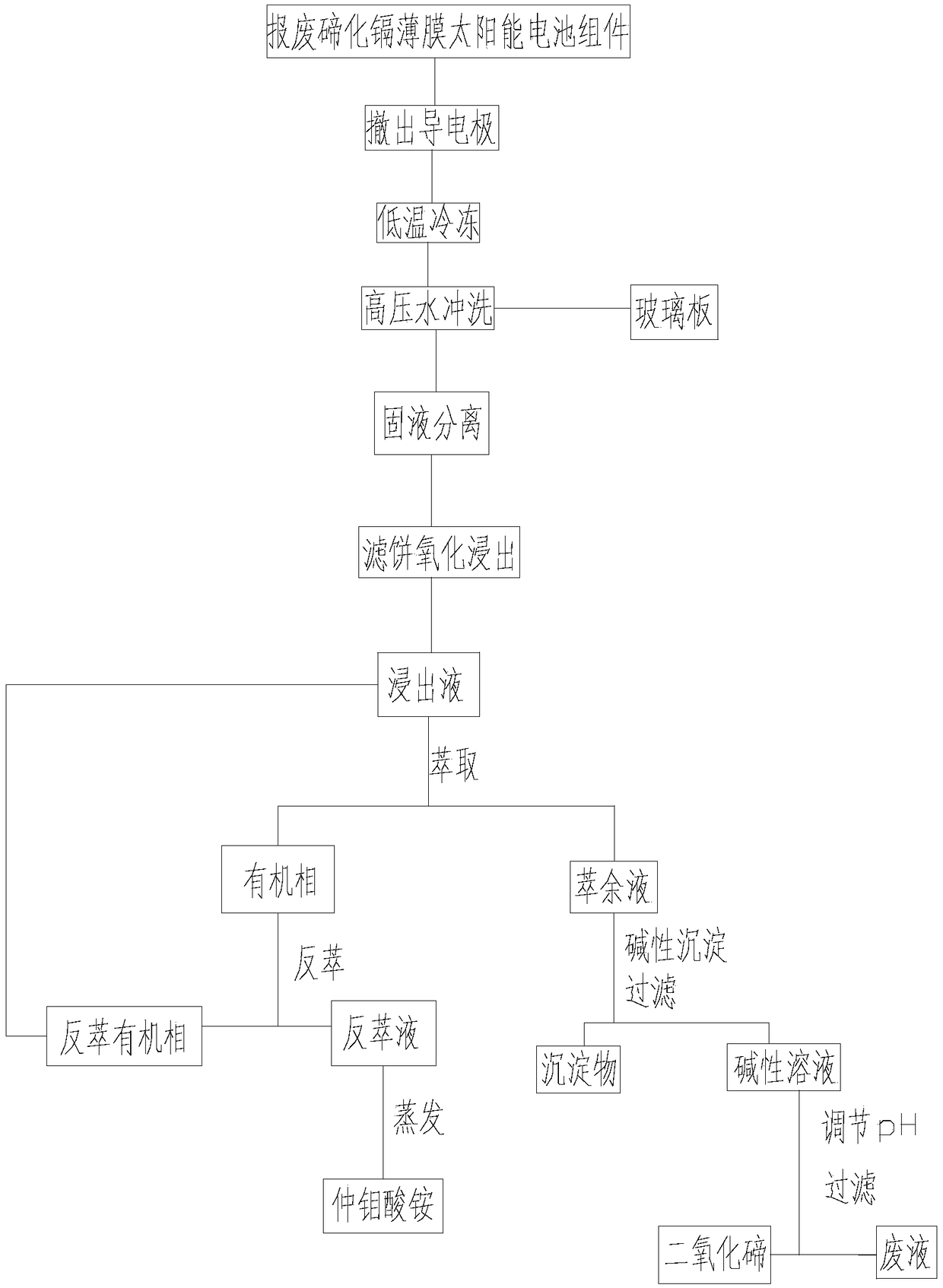

[0024] see figure 1 A low-temperature freezing recovery treatment method for a cadmium telluride thin-film solar cell provided by the invention comprises the following steps:

[0025] (1) Peel off the photovoltaic film layer: remove the back glass and conductive electrodes of the scrapped cadmium telluride thin film solar cell module to obtain a glass substrate with a photovoltaic film layer, and place the glass substrate with a photovoltaic film layer at -10°C The following low-temperature freezing for more than 200s is taken out, and then rinsed with high-pressure water jets. The photovoltaic film layer will gradually separate from the glass substrate with the water flow, and the washed water will be collected together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com