Fluorine-containing dry demoulding agent and preparation method thereof

A release agent and dry technology, which is applied in the field of fluorine-containing dry release agent and its preparation, can solve the problems of increasing the number of demoulding times and a small amount of oil stains, so as to increase the number of demoulding times and excellent demoulding effect , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

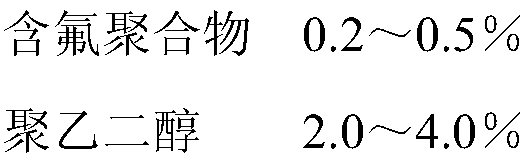

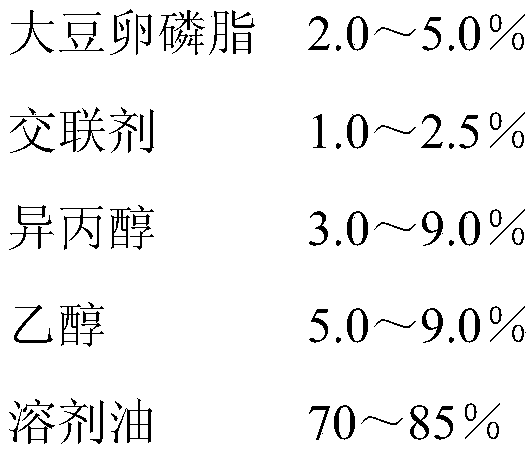

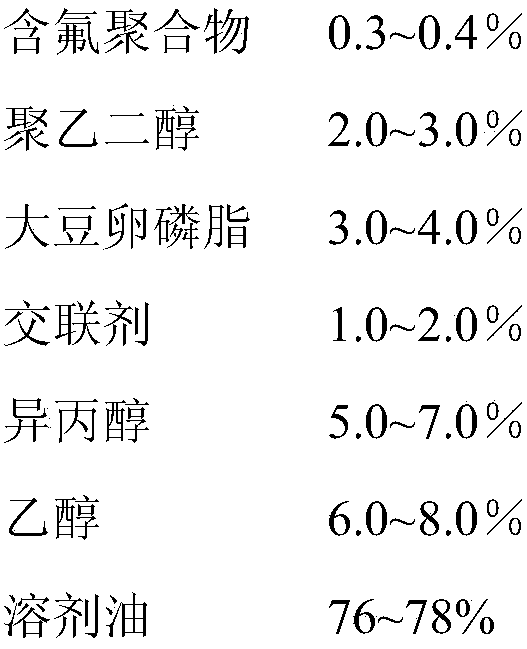

Embodiment l~4

[0034] A fluorine-containing dry mold release agent, the composition and formula of which are shown in Table 1, is prepared by the following process:

[0035] Step 1: Weigh the fluoropolymer and dissolve it in isopropanol while stirring as component A;

[0036] Step 2: Weigh polyethylene glycol (number average molecular weight between 800 and 1000) in isopropanol, heat and stir to dissolve, then add ethanol and stir evenly as component B;

[0037] Step 3: Add component A and component B to solvent oil and stir to dissolve, while stirring clockwise, slowly add crosslinking agent in a linear shape at the vortex of the stirring liquid, and continue stirring for 10 minutes to obtain a milky white product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com