Gasoline blending component oil for cleaning vehicle as well as preparation method and application thereof

A component oil and cleaning vehicle technology, which is applied in the field of petrochemical industry, can solve the problems of excessive olefin content and other oxygenates, the saturated vapor pressure easily exceeds the standard in summer, and the high cost of refinery renovation, so as to achieve low saturated steam pressure, clean raw materials, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

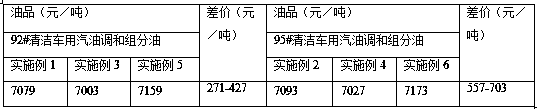

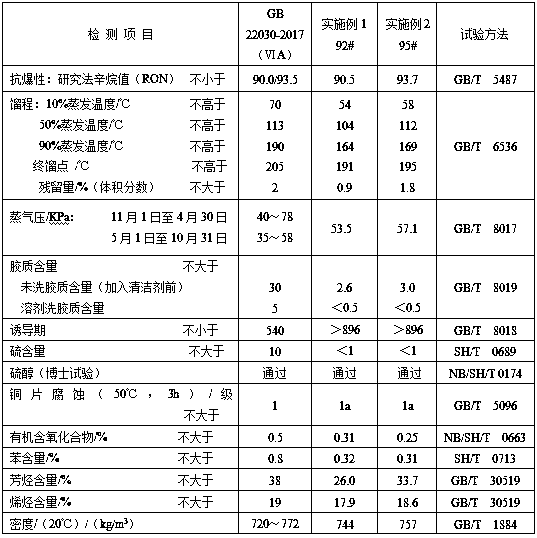

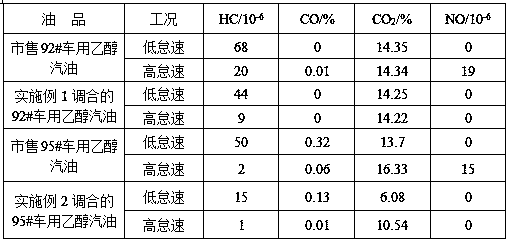

Embodiment 1

[0030] 1. 92# clean vehicle gasoline blending component oil, composed of the following raw materials in volume parts: 92# vehicle ethanol gasoline blending component oil 69 parts, coal-based chemical component oil A 15 parts, coal-based chemical component Oil B 15 parts, non-metallic additive 1 part;

[0031] Wherein, the coal-based chemical component oil A is coal tar 2# produced by Shenmu County Xinyi Energy Chemical Co., Ltd.;

[0032] The coal-based chemical component oil B is a stable light hydrocarbon produced by Shaanxi Future Energy Chemical Co., Ltd.;

[0033] The non-metallic additive is composed of the following raw materials according to 100% by weight: 15% cyclopentane, 35% polyoxymethylene dimethyl ether, 20% isobutanol, and 30% n-butanol oleate;

[0034] 2. The preparation method of 92# clean motor gasoline blending component oil comprises the following steps:

[0035] (1) Preparation of non-metallic additives: under the conditions of stirring and a temperatur...

Embodiment 2

[0040] 1. 95# clean vehicle gasoline blending component oil, composed of the following raw materials by volume: 68.7 parts of 95# vehicle ethanol gasoline blending component oil, 21 parts of coal-based chemical component oil A, coal-based chemical component 9 parts of oil B, 1.3 parts of non-metallic additives;

[0041] Wherein, the coal-based chemical component oil A is coal tar 2# produced by Shenmu County Xinyi Energy Chemical Co., Ltd.;

[0042] The coal-based chemical component oil B is a stable light hydrocarbon produced by Shaanxi Future Energy Chemical Co., Ltd.;

[0043] Described nonmetallic additive, with embodiment 1;

[0044] 2. The preparation method of 95# clean motor gasoline blending component oil is the same as embodiment 1.

Embodiment 3

[0046] 1. 92# clean vehicle gasoline blending component oil, composed of the following raw materials by volume: 63.5 parts of 92# vehicle ethanol gasoline blending component oil, 24 parts of coal-based chemical component oil A, coal-based chemical component 11 parts of oil B, 1.5 parts of non-metallic additives;

[0047] Wherein, the coal-based chemical component oil A is coal tar 2# produced by Shenmu County Xinyi Energy Chemical Co., Ltd.;

[0048] The coal-based chemical component oil B is a stable light hydrocarbon produced by Shaanxi Future Energy Chemical Co., Ltd.;

[0049] The non-metallic additive is composed of the following raw materials according to 100% by weight: 20% cyclopentane, 45% polyoxymethylene dimethyl ether, 15% isobutanol, and 20% n-butanol oleate;

[0050] 2. The preparation method of 92# clean motor gasoline blending component oil comprises the following steps:

[0051] (1) Preparation of non-metallic additives: under the conditions of stirring and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com