Oil shale dry distillation semi-coke dry-process coke-discharging device

A technology of oil shale and dry distillation, which is applied in unloading devices, special dry distillation, coke ovens, etc., can solve the problems of sewage generation, unrecoverable heat, high water consumption, etc., to ensure sealing, break through water restrictions, and eliminate bad The effect of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

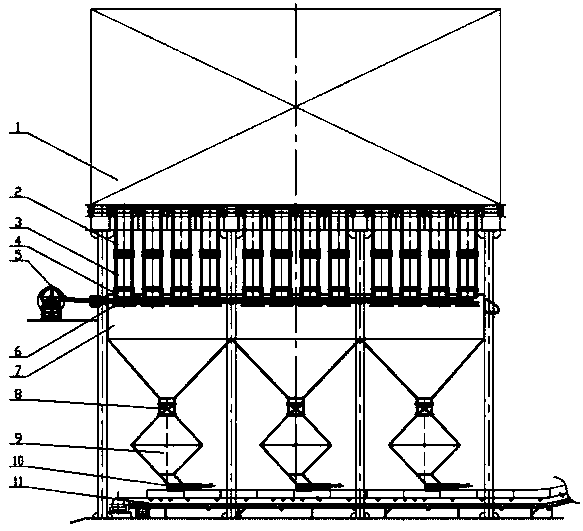

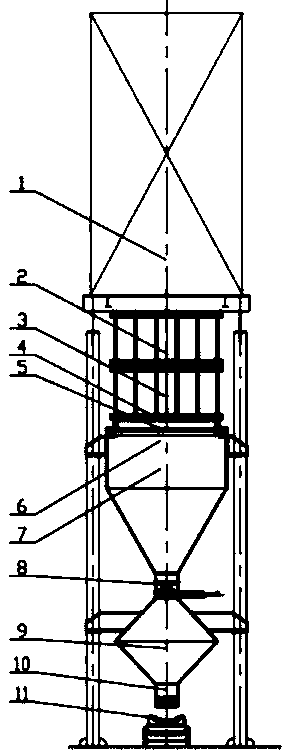

[0033] like figure 1 and figure 2 As shown, an oil shale dry distillation semi-coke dry coking device includes an oil shale dry distillation furnace 1, including a cooling quenching and waste heat recovery unit, a furnace body continuous coke unloading unit and an oil shale dry distillation semi-coke exporting unit, Oil shale retorting furnace 1, cooling coke quenching and waste heat recovery unit, furnace body continuous coke unloading unit and oil shale retorting semi-coke exporting unit are sequentially connected from top to bottom; the cooling quenching and waste heat recovery unit includes water wall 2 and the economizer 3, the oil shale retort 1, the water wall 2 and the economizer 3 are connected in sequence from top to bottom; the continuous coke unloading unit of the furnace body includes a coke guide groove 4, a coke pusher 5, a coke tray 6 and the coke collecting bin 7, the economizer 3, the coke guide groove 4 and the coke collecting bin 7 are connected in sequen...

Embodiment 2

[0035] like figure 1 and figure 2 As shown, an oil shale dry distillation semi-coke dry coking device includes an oil shale dry distillation furnace 1, including a cooling quenching and waste heat recovery unit, a furnace body continuous coke unloading unit and an oil shale dry distillation semi-coke exporting unit, Oil shale retorting furnace 1, cooling coke quenching and waste heat recovery unit, furnace body continuous coke unloading unit and oil shale retorting semi-coke exporting unit are sequentially connected from top to bottom; the cooling quenching and waste heat recovery unit includes water wall 2 and the economizer 3, the oil shale retort 1, the water wall 2 and the economizer 3 are connected in sequence from top to bottom; the continuous coke unloading unit of the furnace body includes a coke guide groove 4, a coke pusher 5, a coke tray 6 and the coke collecting bin 7, the economizer 3, the coke guide groove 4 and the coke collecting bin 7 are connected in sequen...

Embodiment 3

[0038] The oil shale retort furnace 1 is connected to the water-cooled wall 2 by welding, and the water-cooled wall 2 and the economizer 3 are connected by welding. The oil shale retort furnace 1 is connected with the water wall 2 by welding to prevent the leakage of dry distillation gas; the structure of the water wall 1 matches the coke discharge port of the oil shale retort furnace 1, and can be square (applicable when the coke discharge port is a square shape. upright retort furnace) or circular (suitable for the upright retort furnace with a circular coke discharge port); the water wall 2 and the economizer 3 are welded and connected to jointly cool the oil shale retort semi-coke, cool down the coke, quench the coke and recover the waste heat. , the water wall 2 is used to produce high-quality steam, the economizer 3 is used to preheat the boiler feed water, and the oil shale dry distillation semi-coke is cooled after passing through the inner cavity of the two.

[0039]T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com