Rubber type pressure-sensitive adhesive for polyethylene protective film and preparation method thereof

A polyethylene protective film, rubber-type technology, applied in natural rubber adhesives, pressure-sensitive films/sheets, adhesives, etc., can solve the problems of high production cost, low production qualification rate, and difficult peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

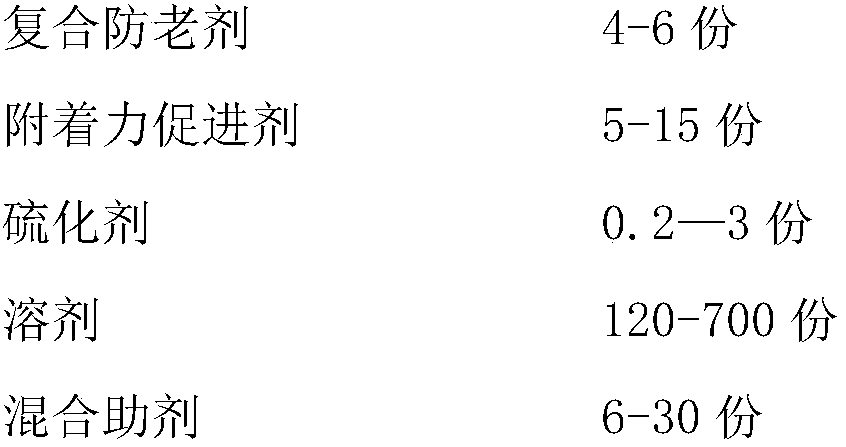

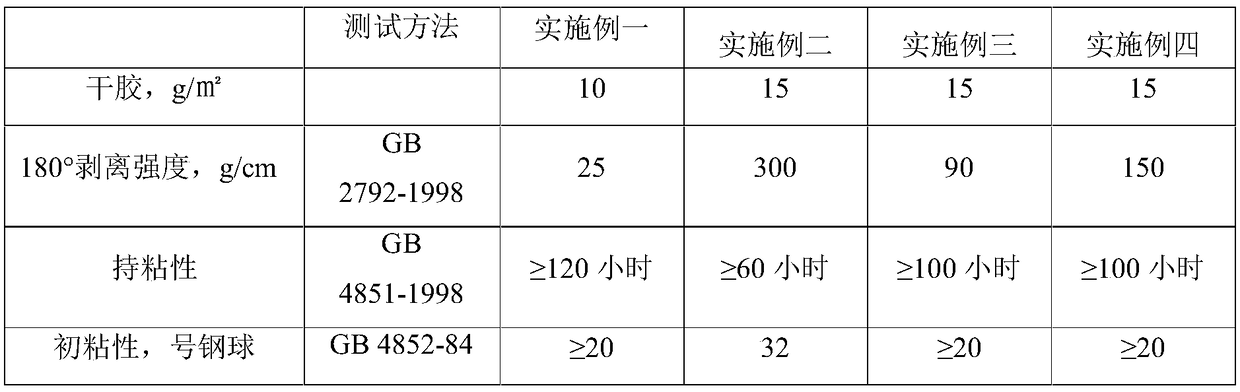

[0018] 30 parts of natural rubber and 5 parts of synthetic rubber are masticated with a rubber mill until the Vickers plasticity reaches 0.5-0.6, and matured for 12-24 hours, and the matured natural rubber and synthetic rubber are mixed with 4 parts of composite anti-aging agent , 0.2 parts of vulcanizing agent are mixed with a rubber mill and thinly passed 3-5 times, and added to the dispersion reactor with nitrogen protection, and 120 parts of solvent, 5 parts of adhesion promoter, and 6 parts of mixing aid are added at the same time. agent, cool to room temperature when a uniform solution is formed, and filter to obtain the rubber-type pressure-sensitive adhesive.

Embodiment 2

[0020] Use a rubber mill to masticate 50 parts of natural rubber and 50 parts of synthetic rubber until the Vickers plasticity reaches 0.5-0.6, and mature for 12-24 hours. Mix the matured natural rubber and synthetic rubber with 6 parts of composite anti-aging agent , 3 parts of vulcanizing agent are mixed with a rubber mill and thinly passed 3-5 times, and added to the dispersion reactor with nitrogen protection, and 700 parts of solvent, 15 parts of adhesion promoter, 30 parts of mixing aid are added at the same time agent, 100 parts of tackifying resin, cool to room temperature when a uniform solution is formed, and filter to obtain the rubber-type pressure-sensitive adhesive.

Embodiment 3

[0022] Plasticize 40 parts of natural rubber and 15 parts of synthetic rubber with a rubber mill until the Vickers plasticity reaches 0.5-0.6, and ripen for 12-24 hours, mix the cured natural rubber and synthetic rubber with 6 parts of composite anti-aging agent , 1.8 parts of vulcanizing agent are mixed with a rubber mill and thinly passed 3-5 times, and added to the dispersion reactor with nitrogen protection, and 400 parts of solvent, 10 parts of adhesion promoter, 8 parts of mixing aid are added at the same time agent, 40 parts of tackifying resin, cool to room temperature when a uniform solution is formed, and filter to obtain the rubber-type pressure-sensitive adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com