A Consolidation Material Used for Stabilization Treatment of Electrolytic Manganese Slag and Its Application

A technology of stabilization treatment and electrolysis of manganese slag, which is applied in the field of solid waste resource utilization, can solve the problems of high production cost and poor consolidation effect of manganese slag, and achieve the effect of reducing production cost, good curing effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

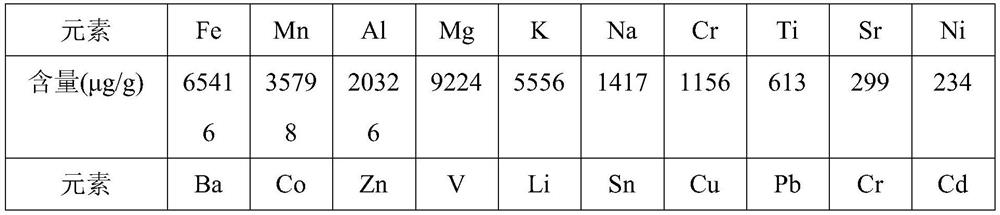

[0035] Preparation of activated electrolytic manganese slag: electrolytic manganese slag and 0.5% NaOH are activated by ball milling-chemical excitation, the ball mill adopts a vertical planetary ball mill, the revolution speed is 250r / min, the autopropagation speed is 60r / min, the ball-to-material ratio is 6:1, and the ball mill is chemically activated The time is 20-60 minutes.

[0036] The mechanically activated electrolytic manganese slag was ball-milled in batches for 20, 40 and 60 minutes.

[0037] According to the activated electrolytic manganese slag: cement clinker: lime: blast furnace slag 40:10:3:47 (mass ratio), mix evenly, and prepare a clean slurry sample of 20mm×20mm×20mm under the condition of water-cement ratio 0.4 (mass ratio) After 7 days of curing in a constant temperature curing box, the impact of mechanical activation time on the properties of the consolidated material was judged by its compressive strength. The analysis results are shown in Table 3.

[...

Embodiment 2

[0042] According to the results of Example 1, the electrolytic manganese slag with a ball milling time of 20 minutes was selected, and different chemical activators were used for chemical excitation research. The chemical activators were added to 0.5% of the mass of the electrolytic manganese slag according to the external mixing method. According to the activated electrolytic manganese slag: cement clinker: lime: blast furnace slag 40:10:3:47 (mass ratio), mix evenly, and prepare a 20mm×20mm×20mm net under the condition of water-cement ratio 0.4 (mass ratio) After the slurry sample was placed in a constant temperature curing box for 7 days, the impact of the chemical activator on the properties of the consolidated material was judged by its compressive strength. The analysis results are shown in Table 4.

[0043] Table 4 The excitation effect of different kinds of chemical stimulants

[0044] stimulant 7d compressive strength / MPa Na 2 CO 3

[0045] It can...

Embodiment 3

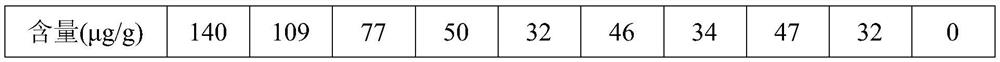

[0047] According to the results of Example 2, the electrolytic manganese slag with a ball milling time of 20 min was selected, and sodium hydroxide was used as the activator to study the activating effect of different contents of the activator. According to the activated electrolytic manganese slag: cement clinker: lime: blast furnace slag 40:10:3:47 (mass ratio), mix evenly, and prepare a 20mm×20mm×20mm clean slurry sample under the condition of water-cement ratio 0.4. After 7 days of curing in the constant temperature curing box, the impact of the chemical activator on the performance of the consolidated material was judged by its compressive strength. The analysis results are shown in Table 5.

[0048] The influence of table 5 sodium hydroxide content on excitation effect

[0049]

[0050] It can be seen from Table 5 that the excitation effect of different contents of sodium hydroxide on the consolidated material is quite different. When the mass fraction of sodium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com