Sterile liquid cross-level transmission device and pharmaceutical workshop

A transmission device and liquid technology, which is applied in the field of aseptic liquid cross-level transmission devices and pharmaceutical workshops, can solve problems such as complex operation and cross-contamination, and achieve the effects of simple operation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiment of aseptic liquid cross-level transmission device

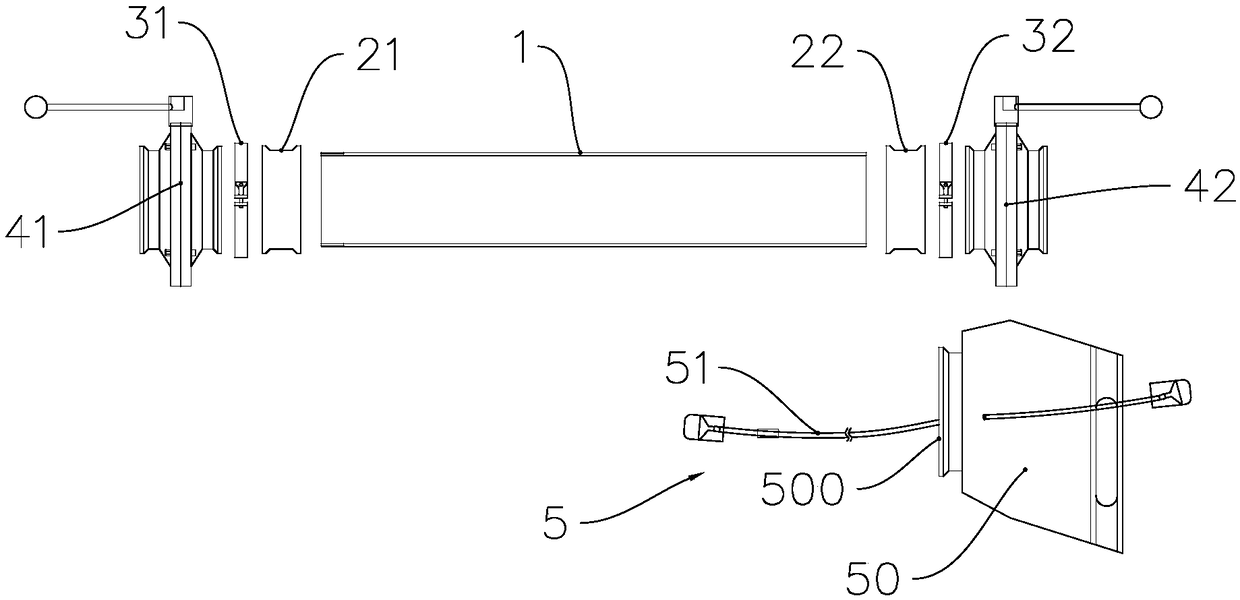

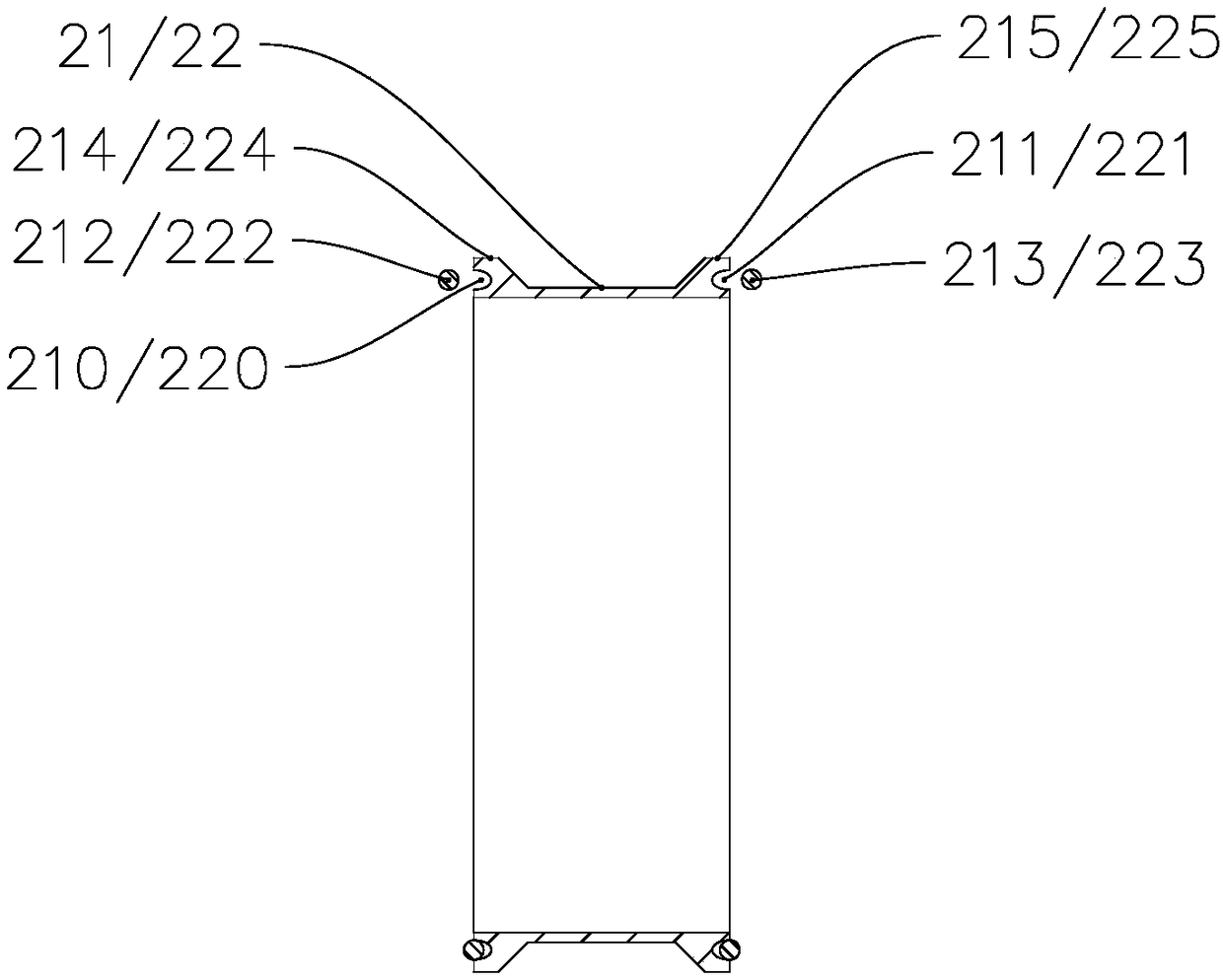

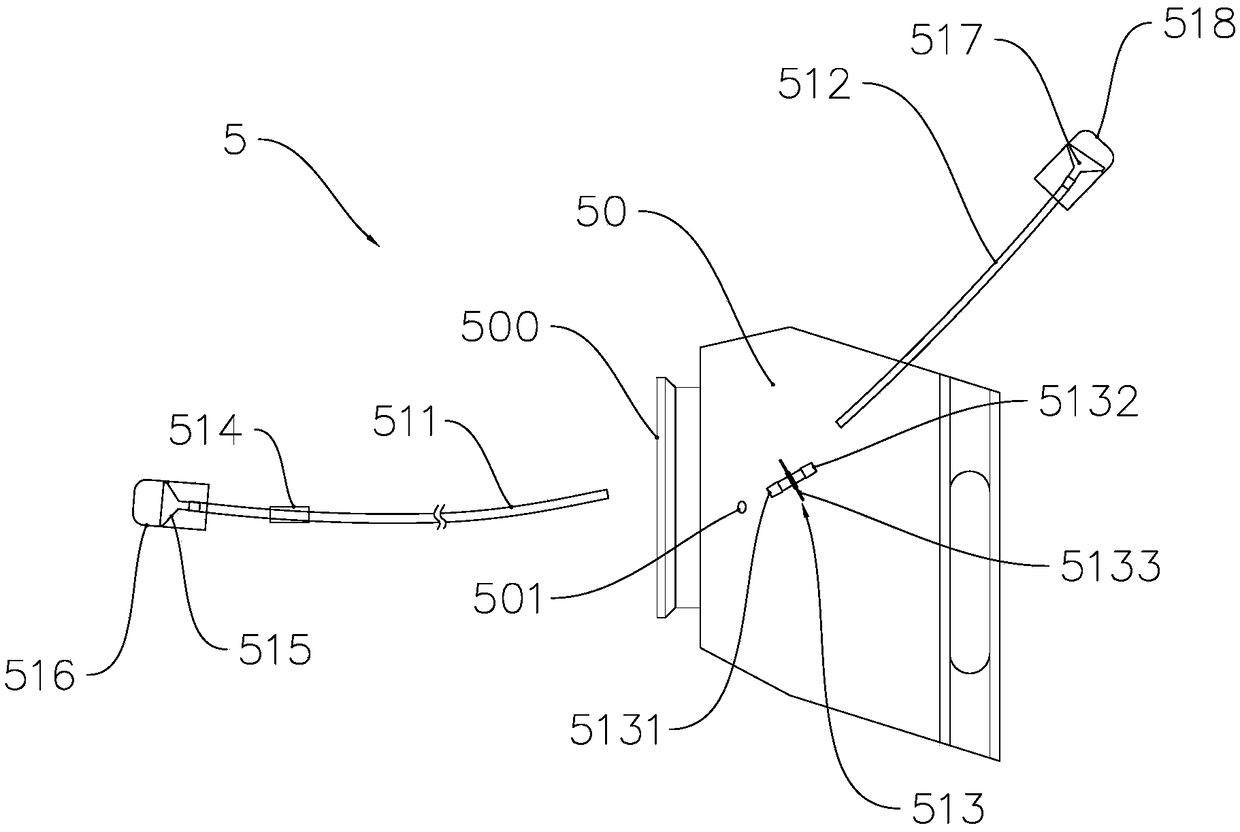

[0034] see figure 1 , figure 1 It is a structural exploded schematic diagram of an embodiment of the aseptic liquid cross-level transmission device of the present invention. In this embodiment, the sterile liquid cross-level transfer device includes a sleeve 1, fastening chucks 21 and 22, clamps 31 and 32, valve bodies 41 and 42 and a disposable liquid transfer bag 5, the sleeve 1 is two A hollow structure with an open end, the casing 1 can use a stainless steel pipe or a plastic pipe, and this embodiment uses a stainless steel pipe. Tightening chucks 21, 22 are installed on the two ends of sleeve pipe 1 respectively, threaded cooperation between sleeve pipe 1 and fastening chucks 21, 22, for example, external threads can be set on sleeve pipe 1, fastening chucks 21, 22 Internal thread is set on 22. The fastening chucks 21 and 22 constitute the fixing components of the casing 1 and are used to fix the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com