Multi-AGV electric power management system and method based on automatic battery changing

A battery replacement and power management technology, applied in circuits or fluid pipelines, electric vehicle charging technology, electric vehicles, etc., can solve the problems of long charging time and reducing the effective working time of AGV, so as to increase the working time and reduce charging. The effect of waiting time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with example diagrams and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

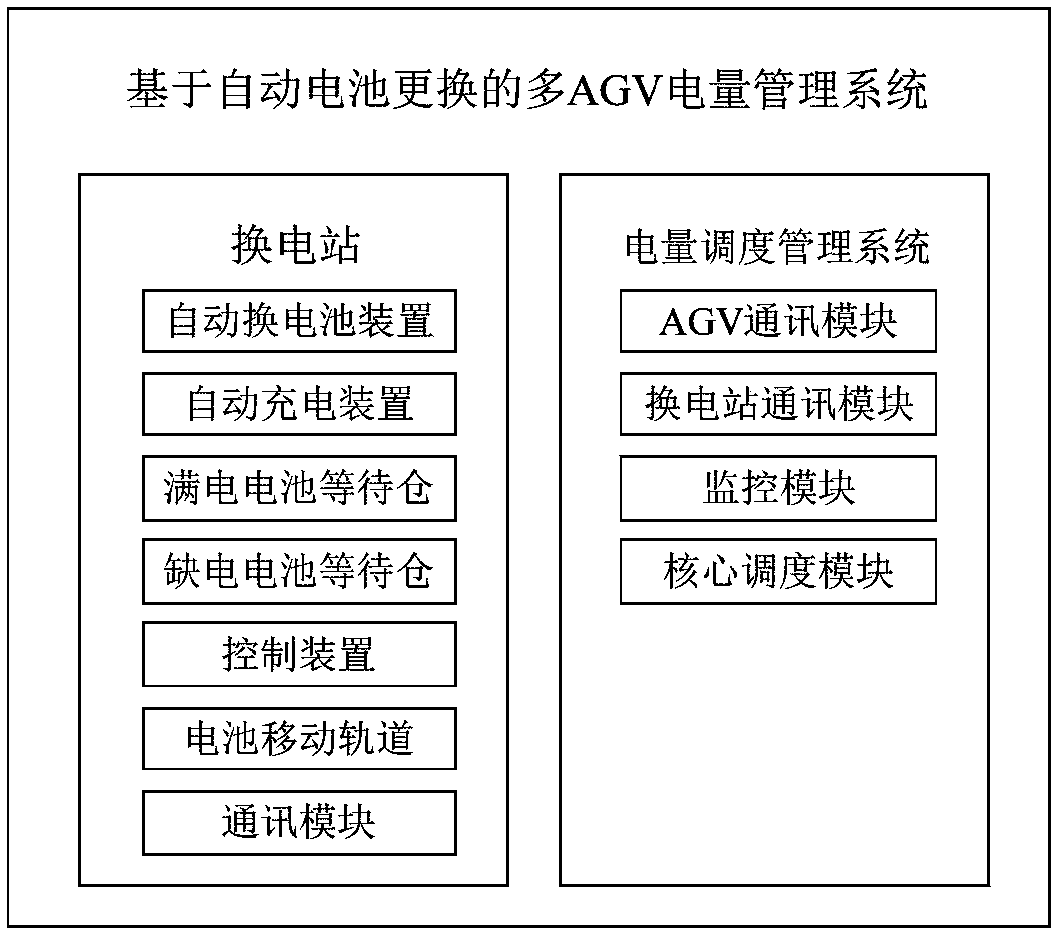

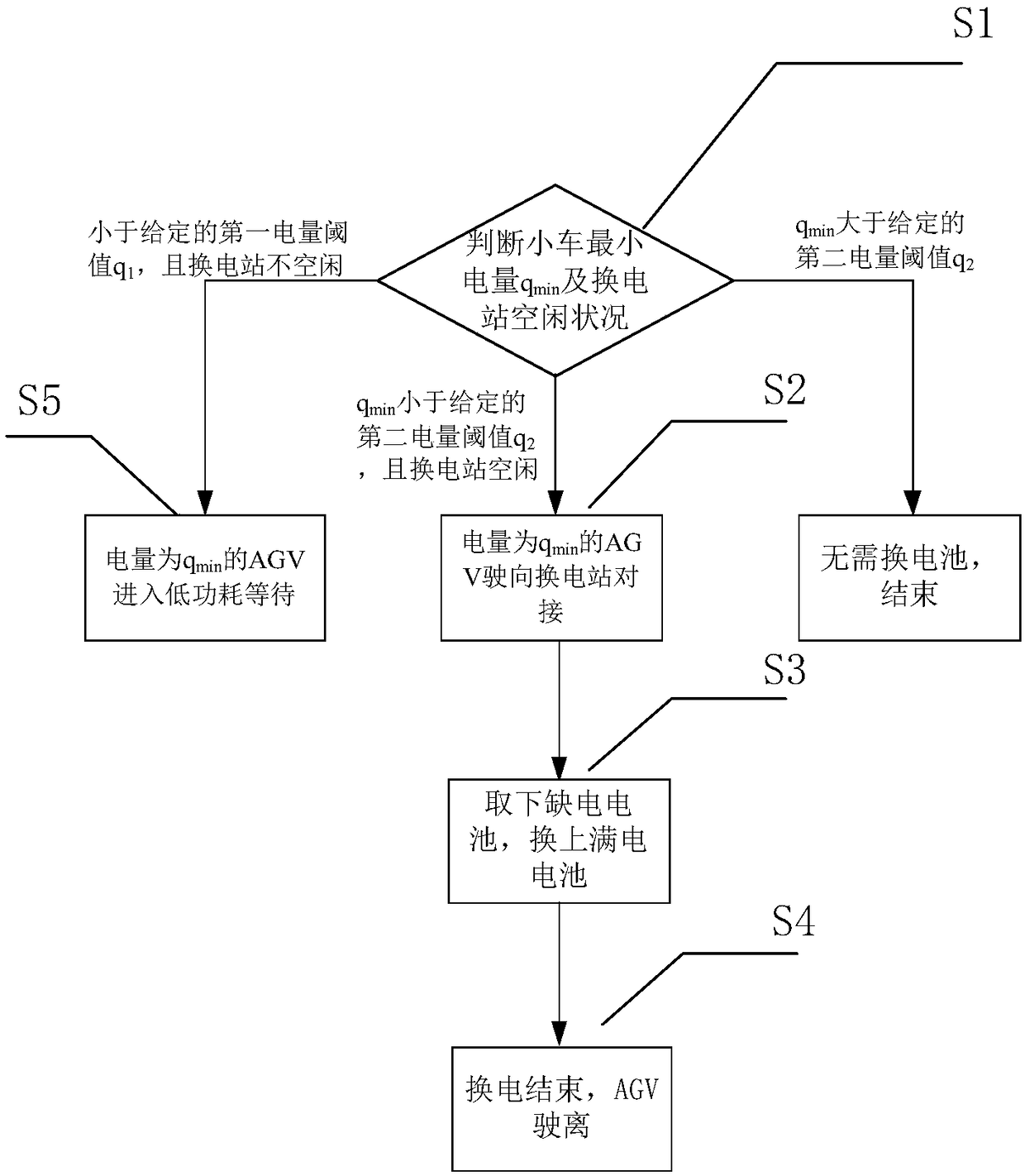

[0046] The present invention proposes a multi-AGV power management system and method based on automatic battery replacement to overcome the use efficiency bottleneck problem faced by the traditional multi-AGV power management and scheduling system management system. Such as figure 1As shown, the multi-AGV power management system based on automatic battery replacement of the present invention includes a power exchange station and a power dispatch management system.

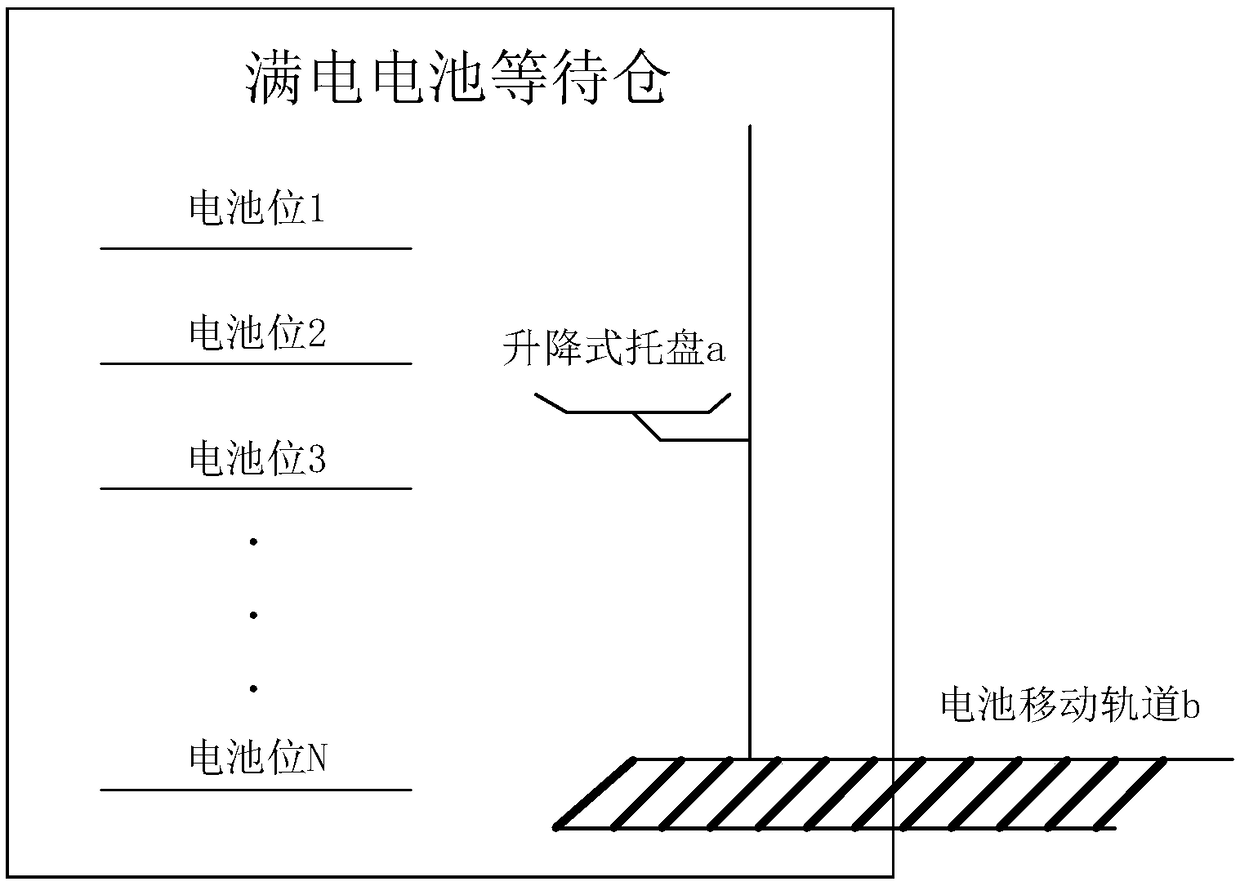

[0047] The battery replacement station includes an automatic battery replacement device, an automatic battery charging device, a fully charged battery waiting compartment, a power-deficient battery waiting compartment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com