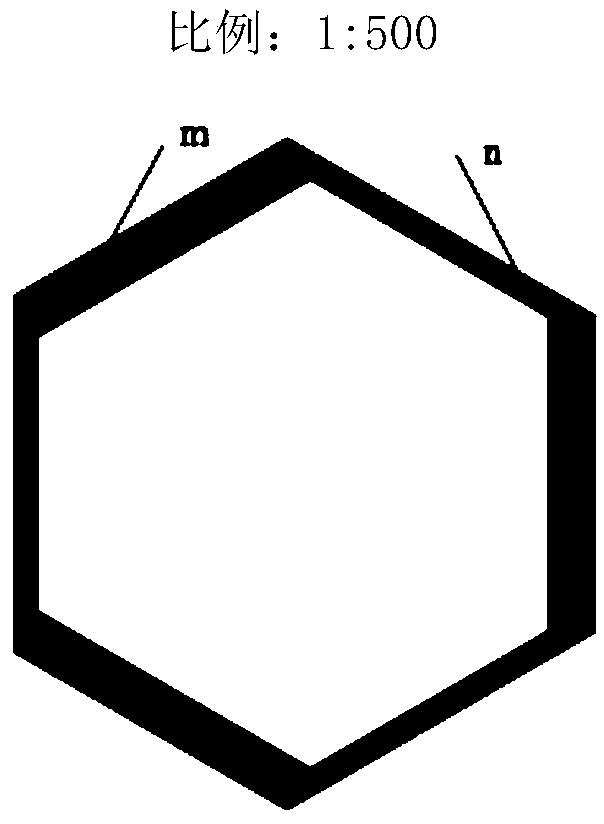

Benzene ring network structure for intaglio printing

A gravure printing and benzene ring technology, applied in the field of benzene ring network structure of gravure printing plates, can solve problems such as water ripples, plate blocking, poor drying, etc., and achieve the effects of increasing the area, improving the printing endurance, and increasing the ink capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

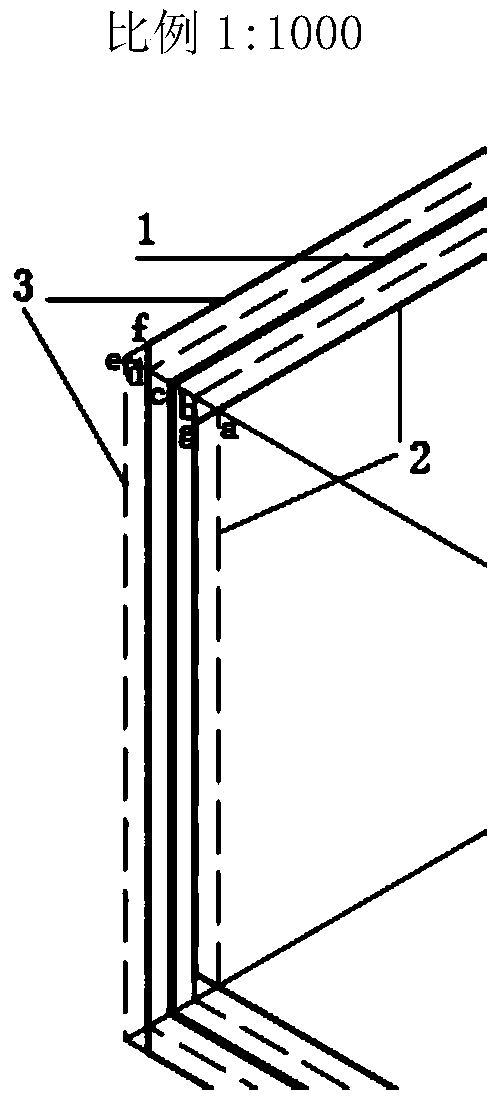

[0023] This patent provides a gravure printing benzene ring network structure. In order to make the purpose, technical solution and effect of this patent more clear and definite, the invention will be further described in detail below with reference to the accompanying drawings.

[0024] The design method of the mesh structure of this patent comprises the following steps:

[0025] The gravure printing benzene ring network structure described in this technology is composed of mesh walls and mesh holes.

[0026] Determine the number of screen lines, screen angle, and screen mode for printing dots.

[0027] The number of screen lines: refers to the number of printed screen lines in each inch of the printed matter, that is, the density of the printed screen lines. The screen line number of the printed dots is set to 70l / cm or 175lpi.

[0028] Screening angle: the angle between the center line of adjacent screen dots on the screen line and the horizontal reference line. It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com