A high-efficiency cleaning device for mechanical parts

A technology for mechanical parts and cleaning devices, applied in the field of cleaning, can solve the problems of wasting time and manpower, the influence of mechanical transmission, inconvenient cleaning, etc., and achieve the effect of easy access and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

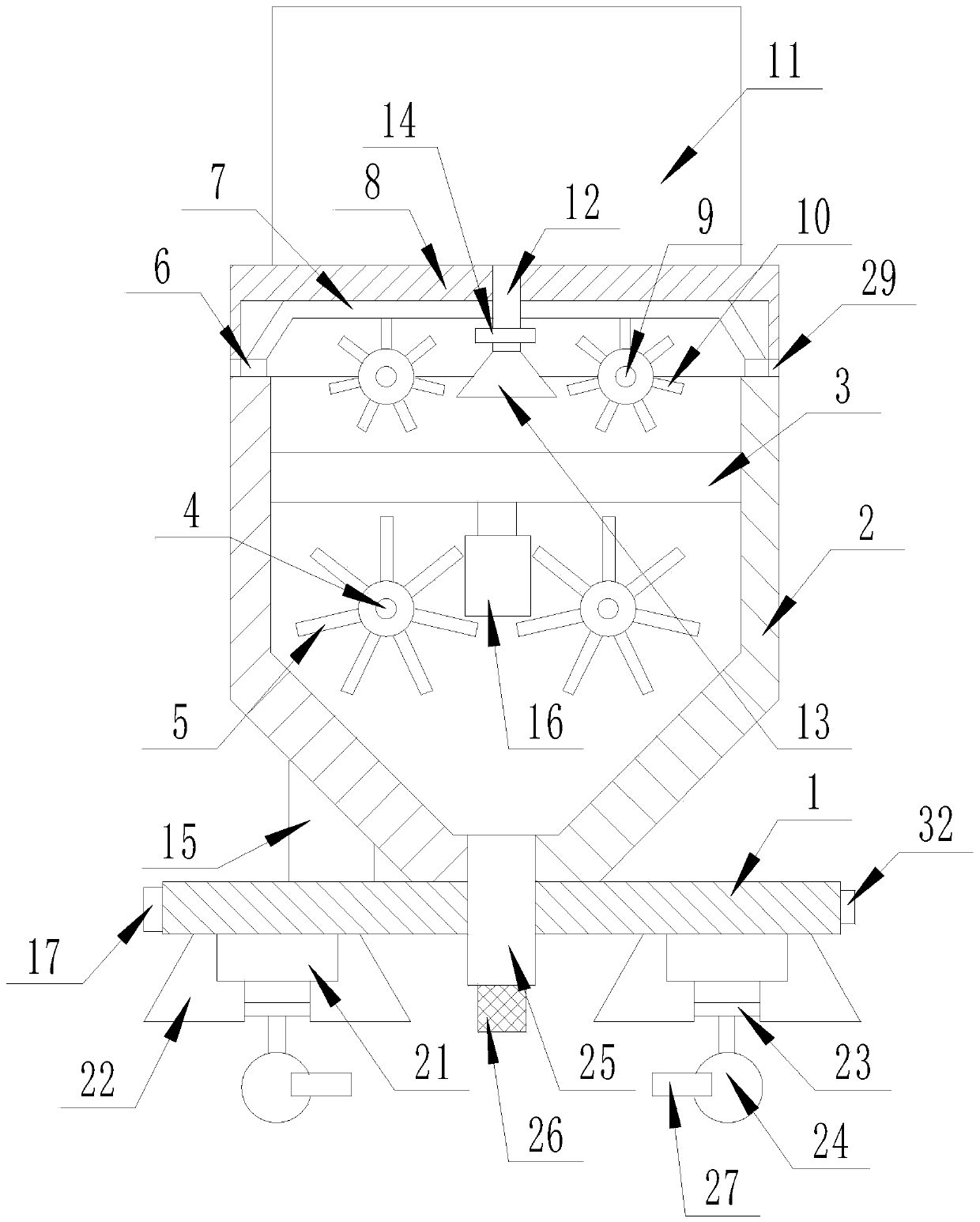

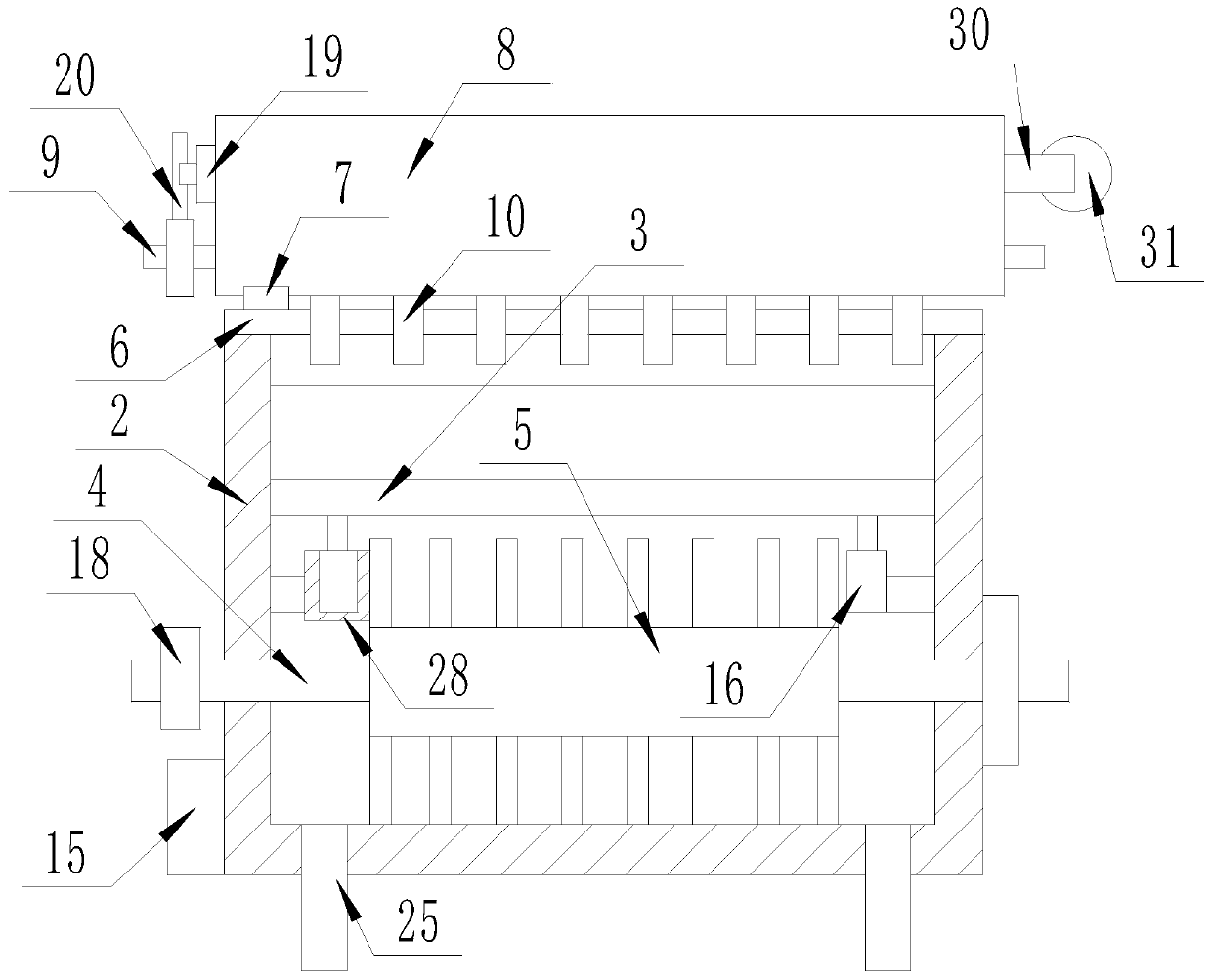

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a high-efficiency cleaning device for mechanical parts includes a strip-shaped bearing base 1, a parts cleaning mechanism is arranged on the upper surface of the strip-shaped bearing base 1, and a moving mechanism is installed on the lower surface of the strip-shaped bearing base 1. The parts cleaning mechanism is mainly composed of the strip-shaped cleaning box 2 arranged on the upper surface of the strip-shaped bearing base 1, the No. 1 strip-shaped opening processed on the upper surface of the strip-shaped cleaning box 2, and the The tool carrier 3, which runs through the strip-shaped cleaning box 2 and is connected to a group of No. 1 horizontal circular shafts 4 below the tool carrier 3, is set on each No. 1 horizontal round shaft 4 and is located in the strip-shaped cleaning box 2 No. 1 cleaning roller brush 5 inside, a group of horizontal slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com