Shredding equipment for construction waste

A technology of crushing equipment and building construction, applied in grain processing and other directions, can solve the problems of land waste, narrow and unobstructed construction site, etc., and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

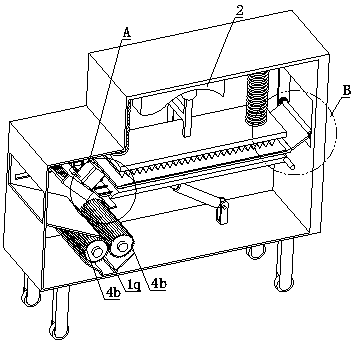

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

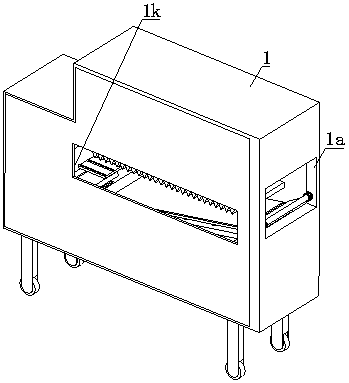

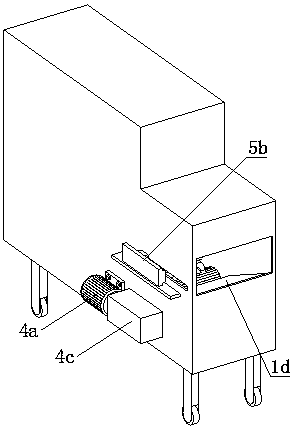

[0027] refer to Figure 1 to Figure 9 The shown crushing equipment for construction waste includes a body 1, a hammer crushing device 2, a squeeze crushing device, an auxiliary device and a balance device 6. The hammer crushing device 2 is installed on the upper part of the body 1, and the hammer crushing device 2 The bottom of the crushing device 2 is provided with a support discharge plate 3 that can be rotated at one end. The support discharge plate 3 is set horizontally under normal conditions, and the extrusion crushing device is arranged below the downstream of the support discharge plate 3. The auxiliary device Installed at the downstream of the support discharge plate 3 and include a load-bearing plate 5a that can be combined with the end of the support discharge plate 3, the bottom of the support discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com