Multiphase fracturing machine set electric drive control system

A technology of control system and electric drive, applied in the direction of control system, AC motor control, electrical components, etc., can solve the problems of increased production cost, large manpower, and material resources in oil fields, and achieve reduced energy consumption costs, improved operating efficiency, and comfortable work sex increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with the accompanying drawings, the present invention is described in detail.

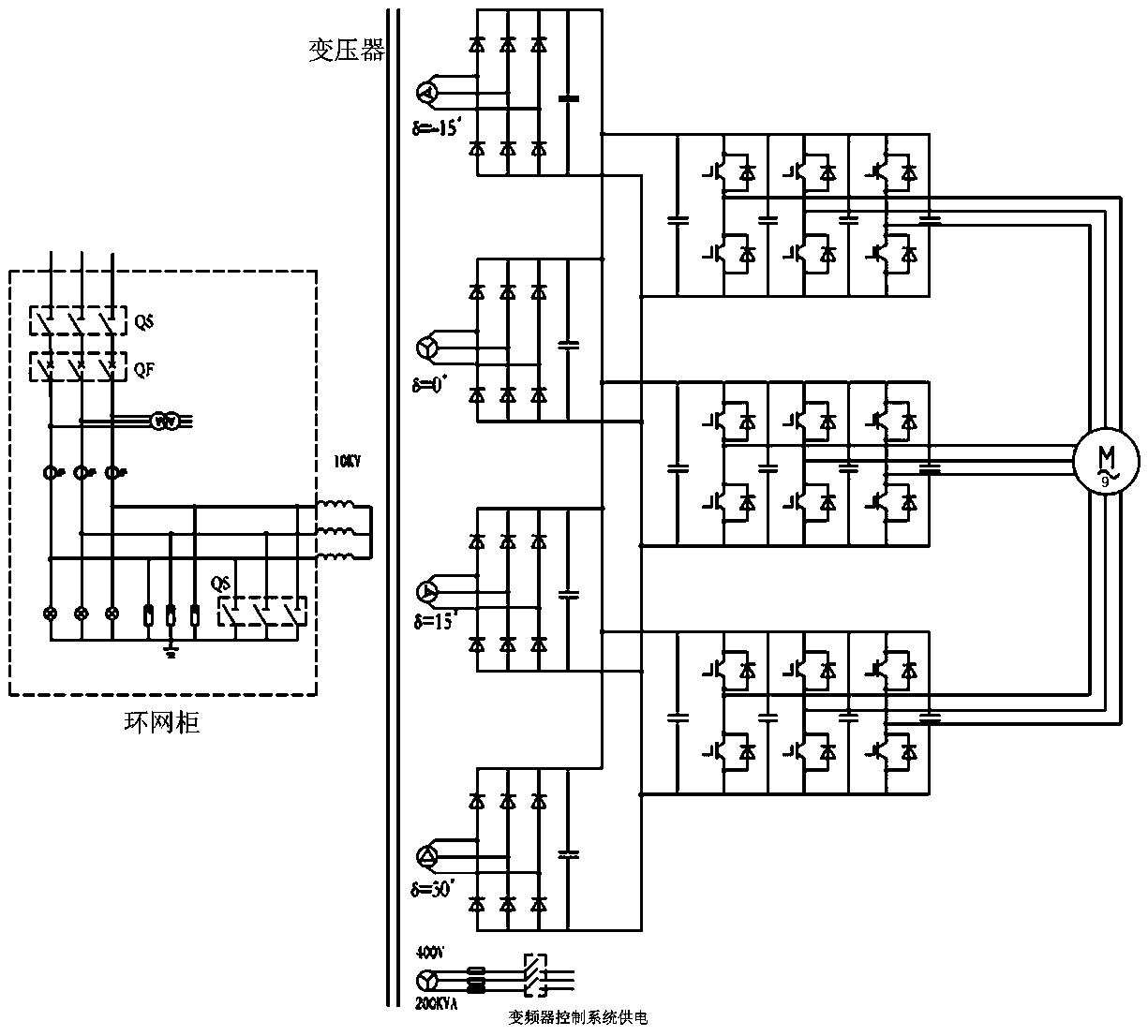

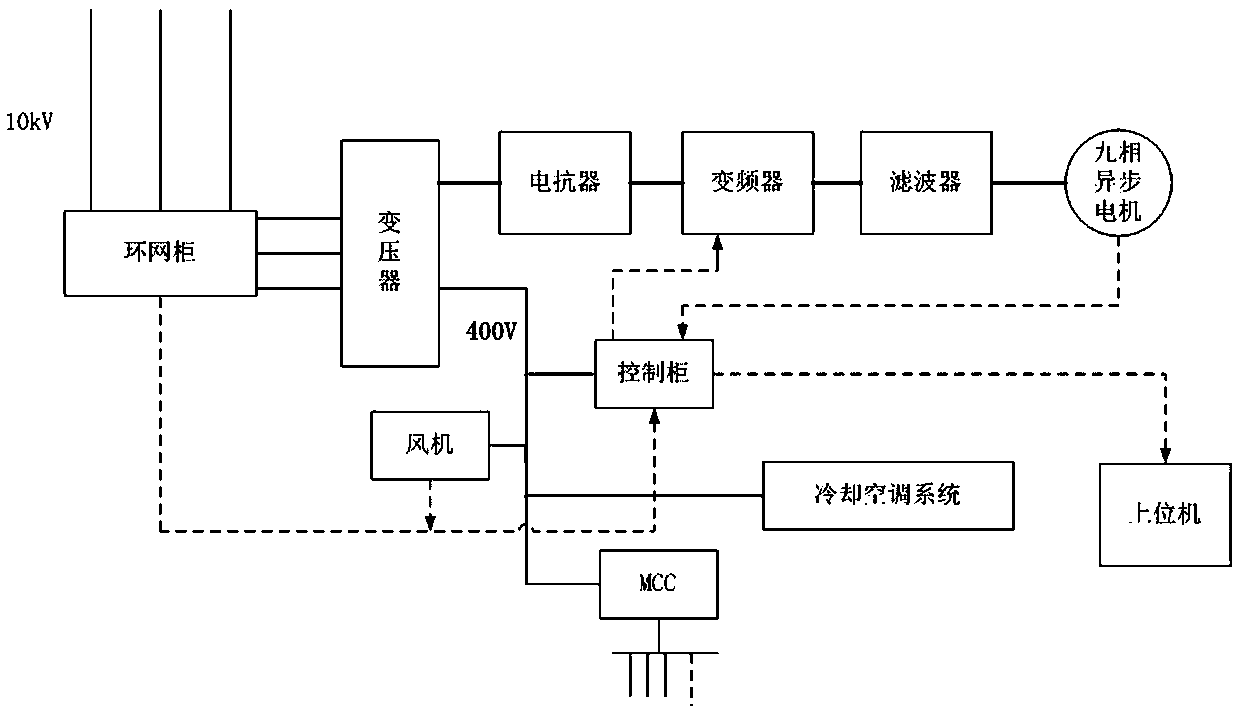

[0017] figure 1 The topology diagram of the main electrical principle, as shown in the figure, uses external high-voltage power supply, and after passing through the ring main unit, it is connected to a phase-shifting transformer. The secondary side output 1 of the phase-shifting transformer has a total of 4 extended side Δ secondary side windings. After being uncontrolled rectified by diodes, they output a common DC bus. For each inverter bridge, the rectified DC power is filtered by capacitors, and the inverter bridge has three bridge arms in total, which are used to realize two-level output voltages. The 9 bridge arms of the three inverter bridges output 9 phases in total and form a 9-phase inverter for driving a 9-phase variable frequency motor.

[0018] The frequency converter outputs three channels of three-phase PWM waves, the amplitude and frequency of each channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com