Optical composite film and preparation method thereof

A technology of optical composite film and diffusion film, which is applied in the field of optical materials, can solve the problems of low production efficiency and large batch-to-batch differences, and achieve the effects of high production efficiency, low cost and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

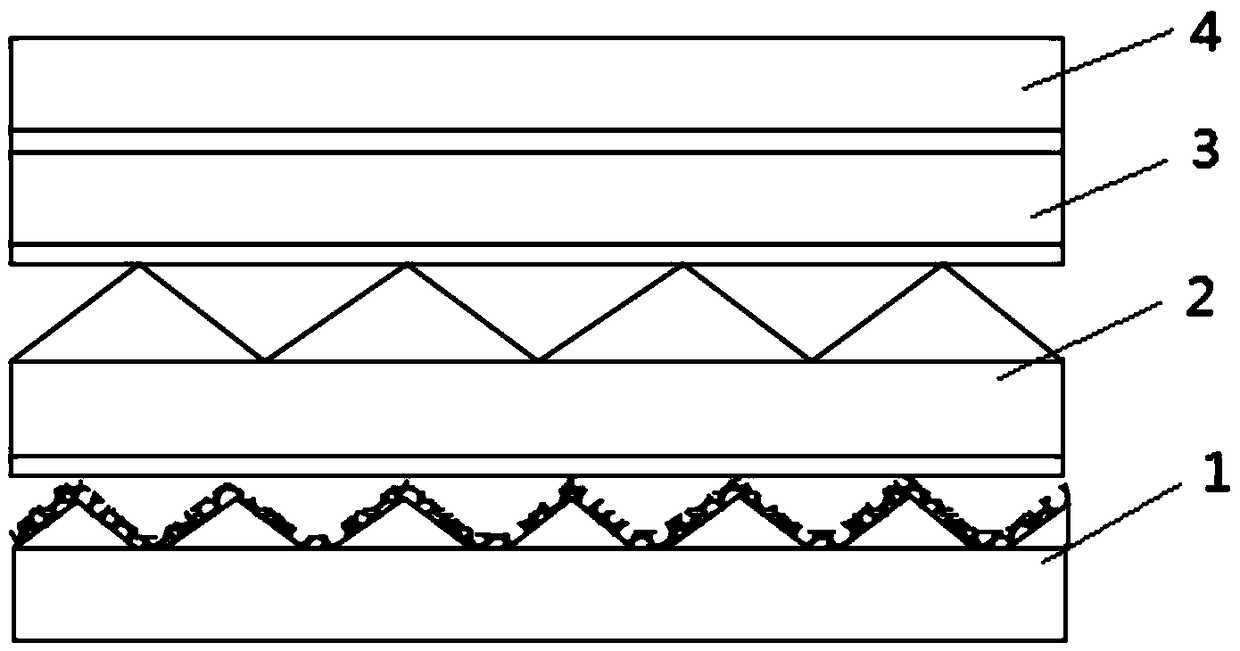

[0083] Such as figure 1 As shown, an optical composite film comprises from bottom to top:

[0084] Diffusion membrane 1,

[0085] a prism layer 2,

[0086] DBEF layer 3,

[0087] And the PSA layer 4 containing particles inside.

[0088] Both the diffusion film 1 and the prism layer 2 have a thickness of 60 μm.

[0089] The optical composite film is composed of four layers of optical films and integrates multiple functions.

[0090] Every two layers are bonded by polyurethane glue.

[0091] Among them, the diffusion film 1 has the function of structural diffusion, which adopts a combination of a pillar-shaped structure (ie, the prism layer 2) and sandblasting on the surface of the pillars to form a certain roughness, thereby improving the diffusion effect and reducing the luminance. Specifically, the diffusion film 1 has a prism structure, and there is a concave-convex structure imitating a diffusion structure between the prism peak structures, and the Rz is about 30um. ...

Embodiment 2

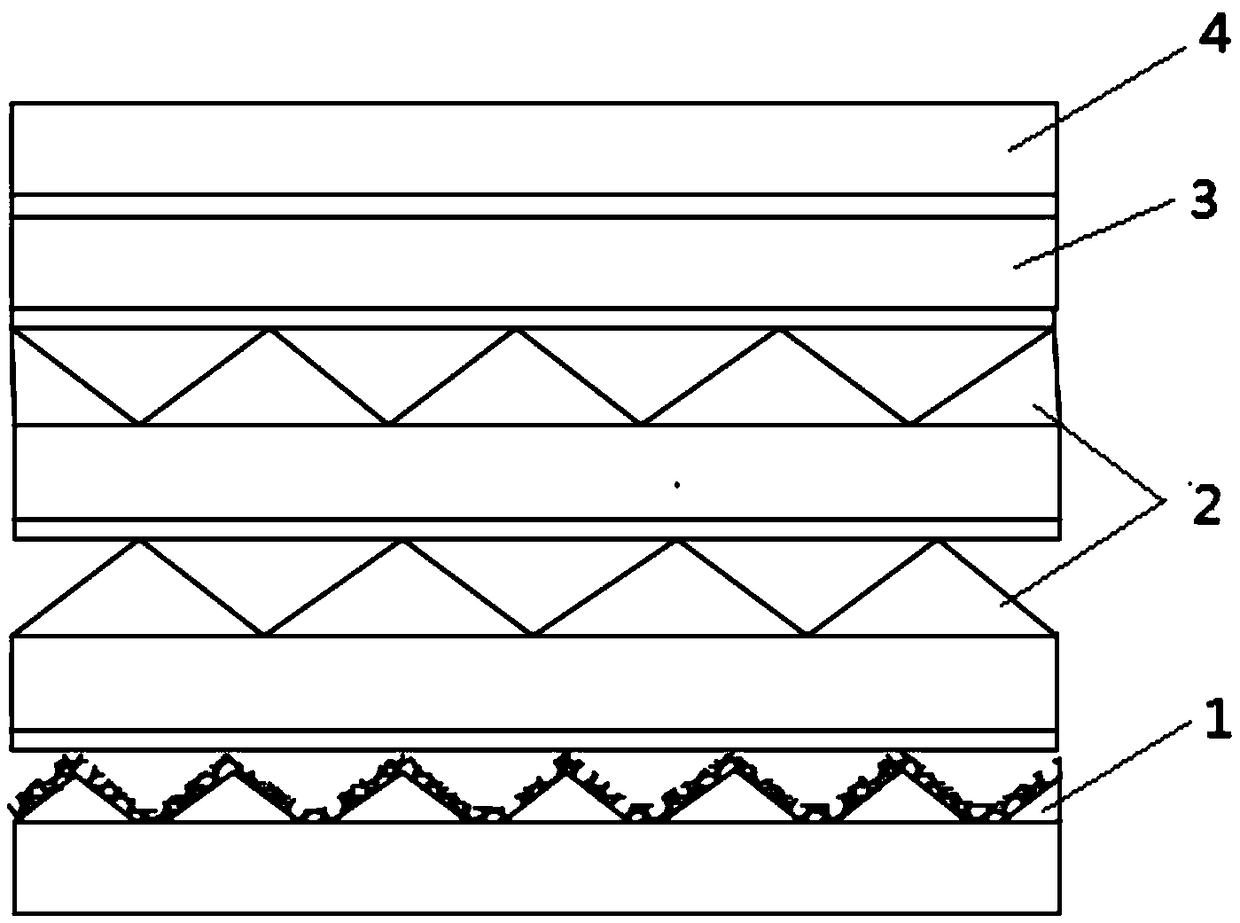

[0102] Such as figure 2 As shown, an optical composite film comprises from bottom to top:

[0103] Diffusion membrane 1,

[0104] two prism layers 2,

[0105] DBEF layer 3,

[0106] And the PSA layer 4 containing particles inside.

[0107] Both the diffusion film 1 and the prism layer 2 have a thickness of 60 μm.

[0108] The optical composite film is composed of four layers of optical films and integrates multiple functions.

[0109] Every two layers are bonded by polyurethane glue.

[0110] Among them, the diffusion film 1 has the function of structural diffusion, which adopts a combination of a pillar-shaped structure (ie, the prism layer 2) and sandblasting on the surface of the pillars to form a certain roughness, thereby improving the diffusion effect and reducing the luminance. Specifically, the diffusion film 1 has a prism structure, and there is a concave-convex structure imitating a diffusion structure between the prism peak structures, and the Rz is about 30u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com