A method for loading explosives in deep hole loosening blasting

A technology of loose blasting and explosives, which is applied in the field of blasting. It can solve the problems of the wrong position of the gun delivery, the mass of the gun barrel, and the inability to quickly recover the dumb gun, etc., and achieve the effect of reducing the cost of materials, accurate feeding position, and fast and stable charging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

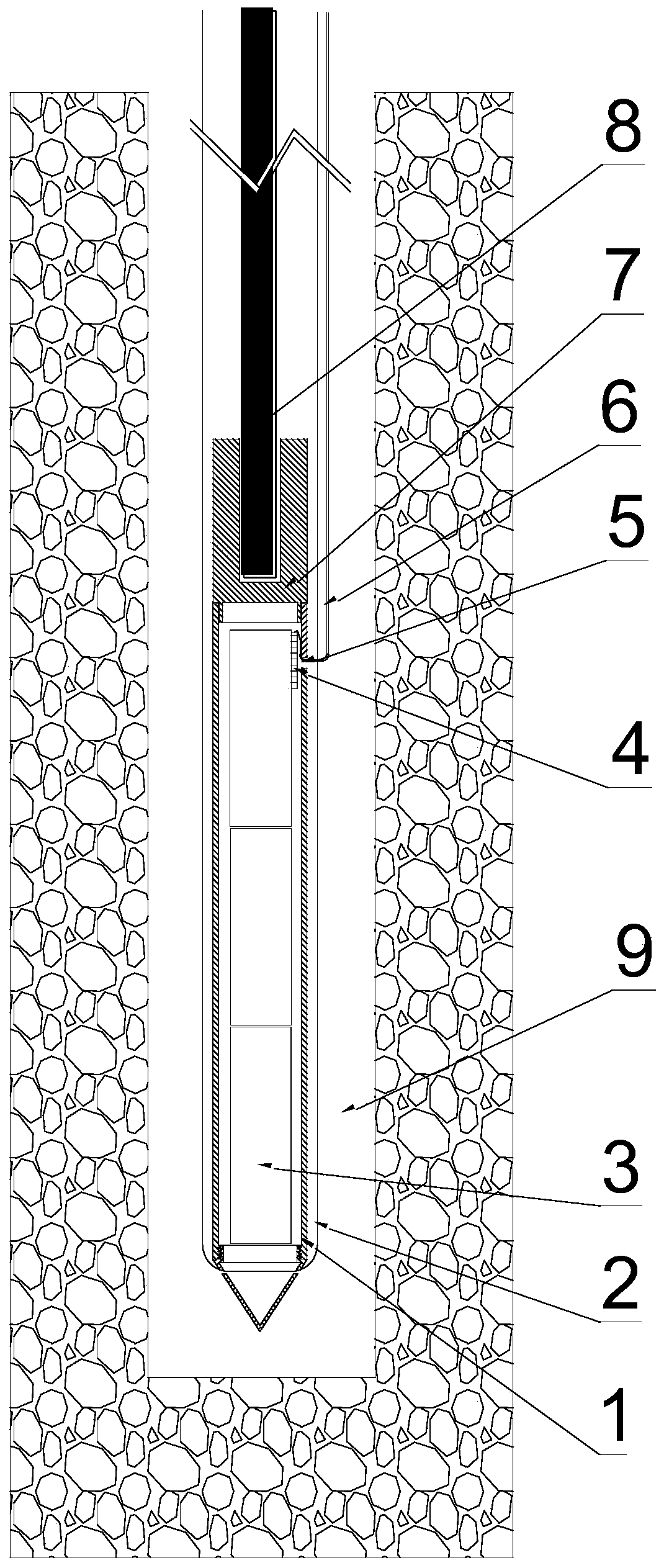

[0030] Such as figure 1 Shown, a kind of deep hole loosening blasting dress explosive method comprises the following steps:

[0031] a. Construct the loosening and blasting drilling 9 in front of the excavation working face according to the conventional method, the aperture and hole depth are selected according to the needs, and a predetermined position for blasting and loosening is set in front of the stress concentration area of the excavation head;

[0032] The larger the aperture of the blasting hole 9 is, the more the charge is, the greater the blasting energy is, and the guiding and compensation effects are more obvious, which is more conducive to the formation and development of cracks; however, after the aperture of the blasting hole increases to a certain value, , the rate of increase of air permeability coefficient gradually decreases with the increase o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com