Slot-in-place prefabricated light-weight round-hole partition wallboard and manufacturing method thereof

A technology for partition boards and round holes, which is applied to walls, manufacturing tools, building components, etc., can solve the problems of increasing wall construction costs, increasing construction costs, and reducing sound insulation effects, so as to promote the standardization process and reduce labor costs. Good strength and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

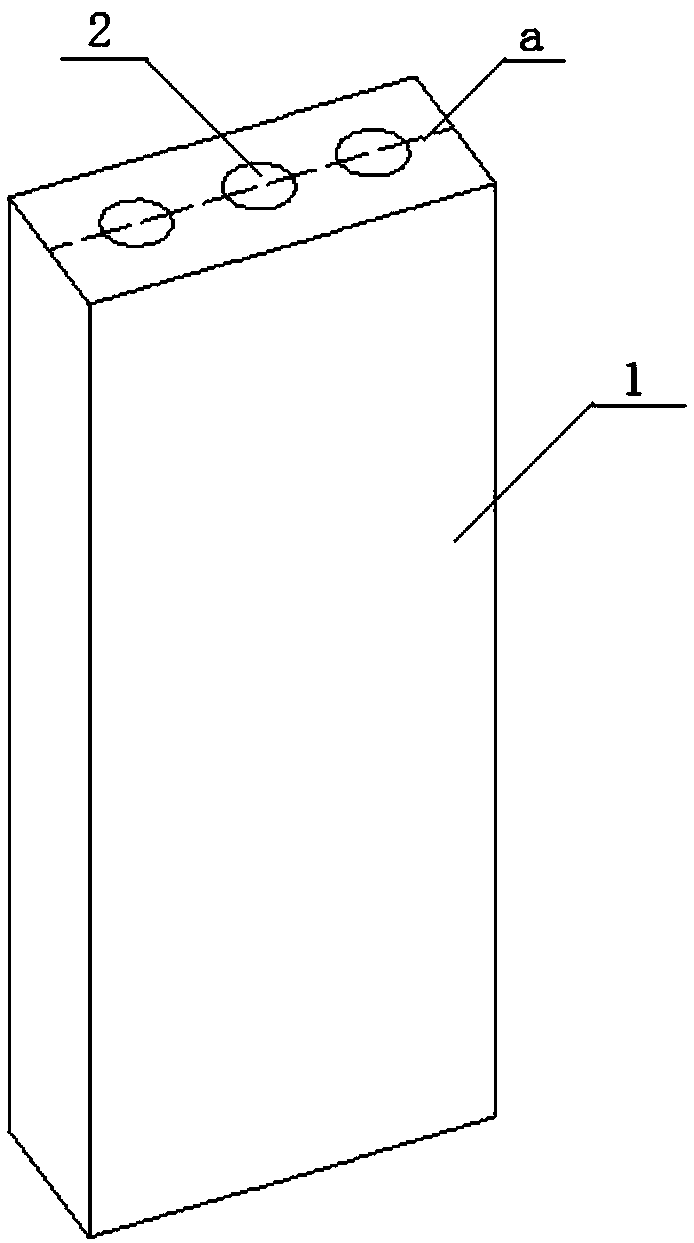

[0058] The specifications of the prefabricated lightweight round hole partition board (length╳width╳thickness) are: 3000mm╳600mm╳90mm (the thickness of the board body 1 is T=90mm);

[0059] The application occasions are: kitchen, bathroom partition wall;

[0060] The partitions of the kitchen and bathroom are located indoors. The prefabricated lightweight insulation wall panels used in this occasion require certain sound insulation performance and supporting force. The minimum thickness X between the outer sides of the plate body 1 is 15mm, and the pipelines 5 in the kitchen and bathroom are mainly cold and hot water pipes and electric wire pipes with a pipe diameter of d=20mm, then:

[0061] The diameter D=T-2X=90mm-2╳15mm=60mm of circular hole 2 (heat transfer coefficient is between 1.113-1.575);

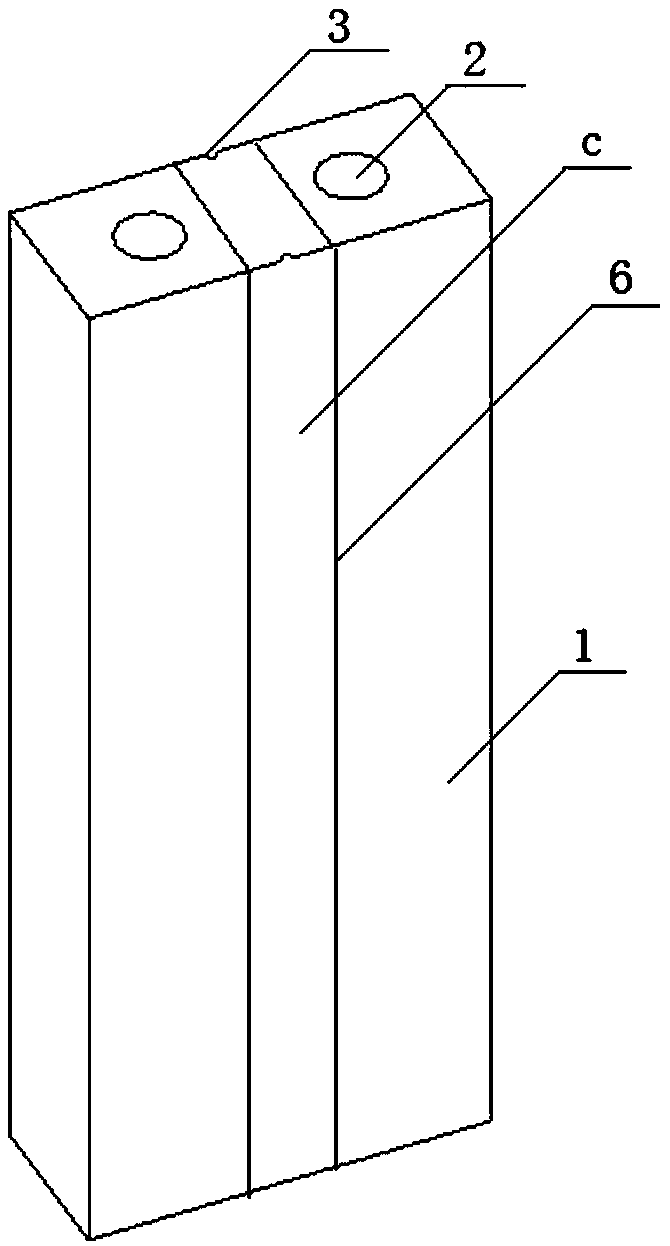

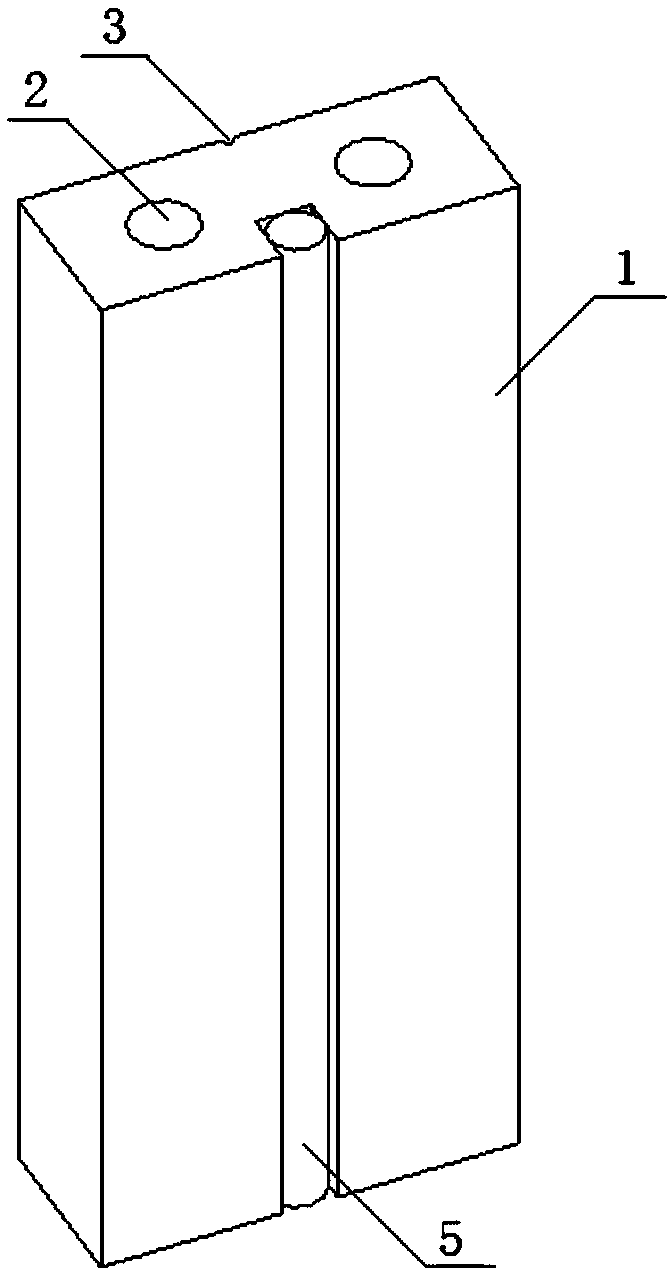

[0062] The length of the connecting line between the centers of two adjacent round holes 2 (distance between two slotted marks 3) Z=2X+d+D=2╳15mm+20mm+60=110mm;

[0063] The dis...

example 2

[0065] The specifications of the prefabricated lightweight thermal insulation wallboard (length╳width╳thickness) are: 3000mm╳600mm╳120mm (the thickness of the board body 1 is T=120mm);

[0066] The application occasions are: peripheral wall, bedroom partition wall;

[0067] The bedroom partition wall, especially the peripheral protective wall, has higher requirements on the sound insulation performance and supporting force of the prefabricated lightweight thermal insulation wall panel. The minimum thickness X between the outer sides of the plate body 1 = 30mm; the pipeline 4 is mainly a wire tube with a diameter of d = 20mm, then:

[0068] The diameter D=T-2X=120mm-2╳30mm=60mm of the round hole 2 (the heat transfer coefficient is below 1.113);

[0069] The length of the connecting line between the centers of two adjacent round holes 2 (distance between two slotted marks 3) Z=2X+d+D=2╳30mm+20mm+60=140mm;

[0070] The distance between the grooved area line 6 and the center of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com