Label insertion execution mechanism and automatic label insertion execution method

An actuator and label insertion technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of high production cost and complexity, achieve the effect of convenient operation, simple structure of the device, and increase the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

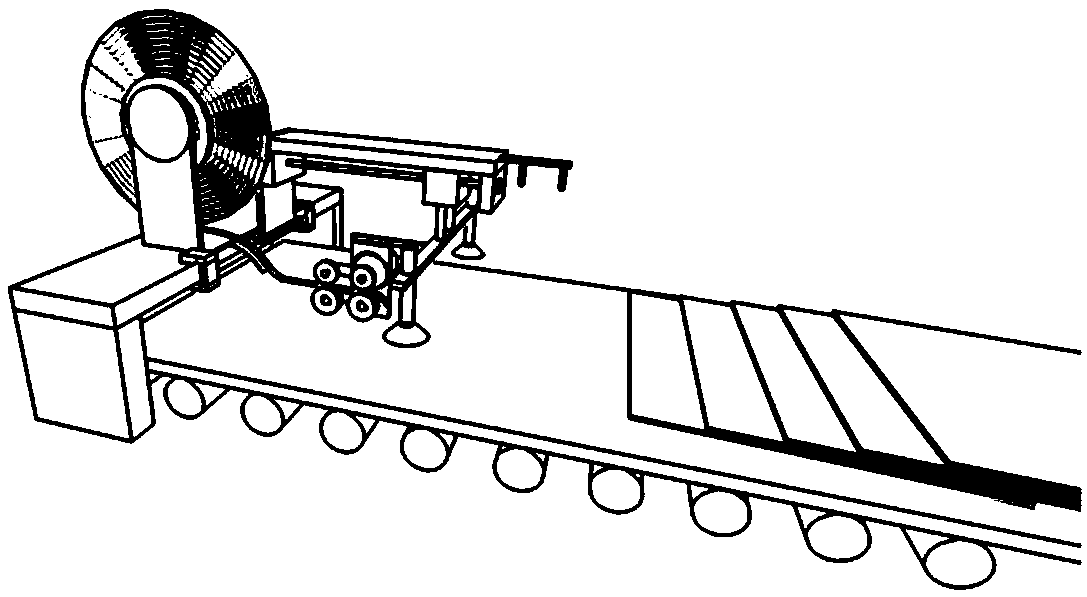

[0039] Such as figure 1 As shown, the label insertion actuator of the present invention includes a base 1, a lead screw slider assembly 2, a vacuum suction cup assembly 3, a paper cutting assembly 4 and a controller (not shown in the figure), and the lead screw slider assembly 2 The first end of the first end is fixed on the base 1, the second end is extended upstream, the vacuum suction cup assembly 3 is slidably connected under the screw slider assembly 2, and the paper cutting assembly 4 is fixed on the vacuum through a mounting support. The downstream side of the suction cup assembly; the paper cutting assembly 4 is provided with a label paper channel; the controller controls the label insertion actuator to realize automatic label insertion.

[0040] Such as figure 2 As shown, the label insertion actuator further includes a sensor group 5, which is arranged on the upstream side of the second end of the lead screw slider assembly 2, and is used to detect incoming signals ...

Embodiment 2

[0054] This embodiment provides an automatic label insertion execution method, which is used for the automatic label insertion actuator of the above-mentioned paper assembly line, and the controller of the automatic label insertion actuator is also connected with a timer A, a timer B, a timer C and a timer d.

[0055] The automatic label insertion execution control method specifically includes the following steps:

[0056] S1, obtain the speed v of the paper conveyor belt;

[0057] S2, according to the speed v of the conveyor belt, obtain the delayed start time T of the insertion actuator delay ;

[0058] S3, real-time detection of the output signal of the Hall sensor at the paper cutter, when the output signal is the N+1th sheet of paper, start the timer C to start counting, when the timer time reaches T delay Finally, start the timer D to start counting, and start the servo motor 21 and the pneumatic push rod 41 to start working at the same time. When the vacuum chuck 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com