Graphite sheet supplementing machine

A technology of graphite flakes and refilling, which is applied in the field of refilling machines, can solve the problems of affecting product quality, missing graphite flake refilling, and low degree of automation, achieving the effects of high degree of automation, reducing production costs, and improving quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

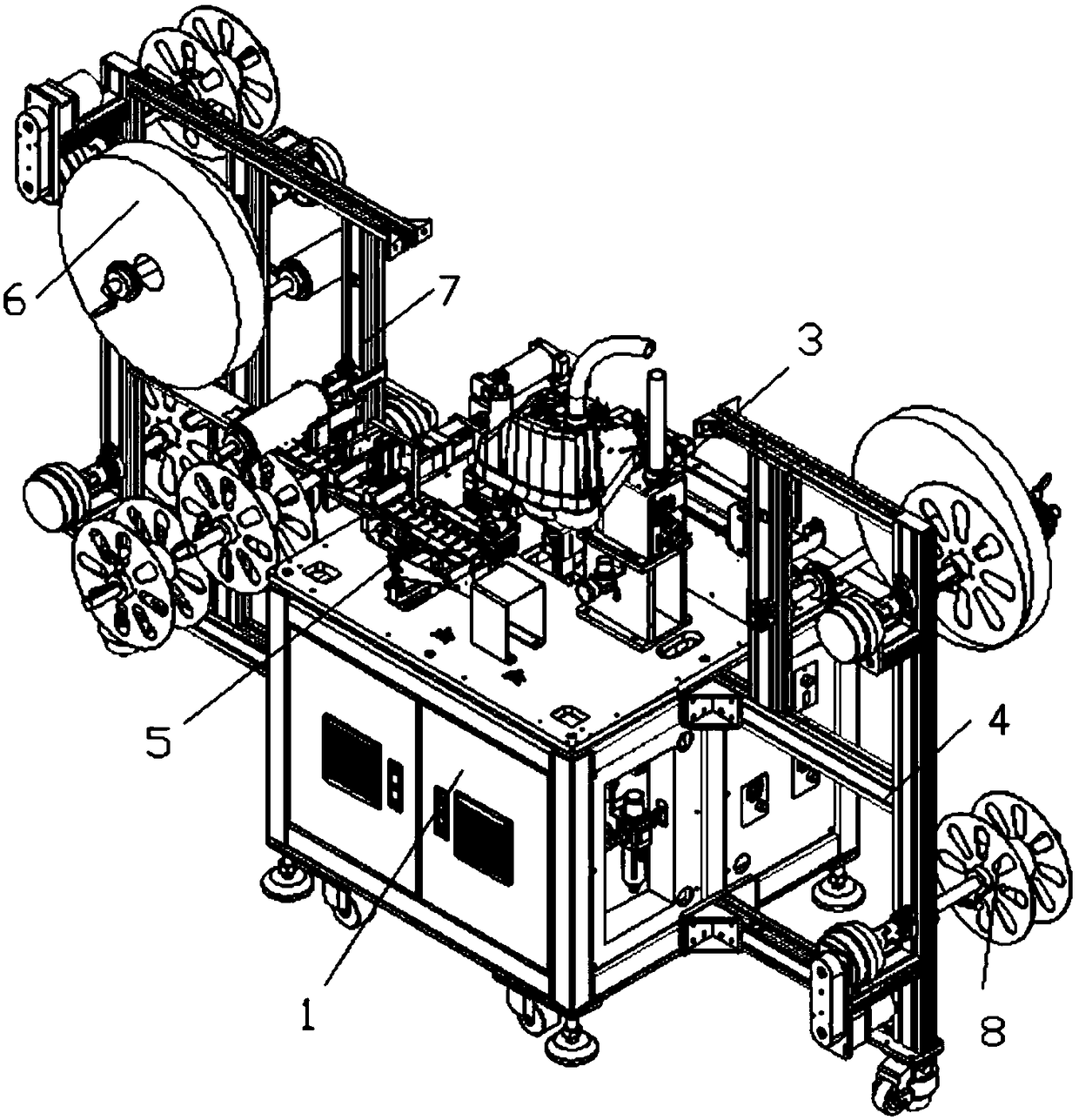

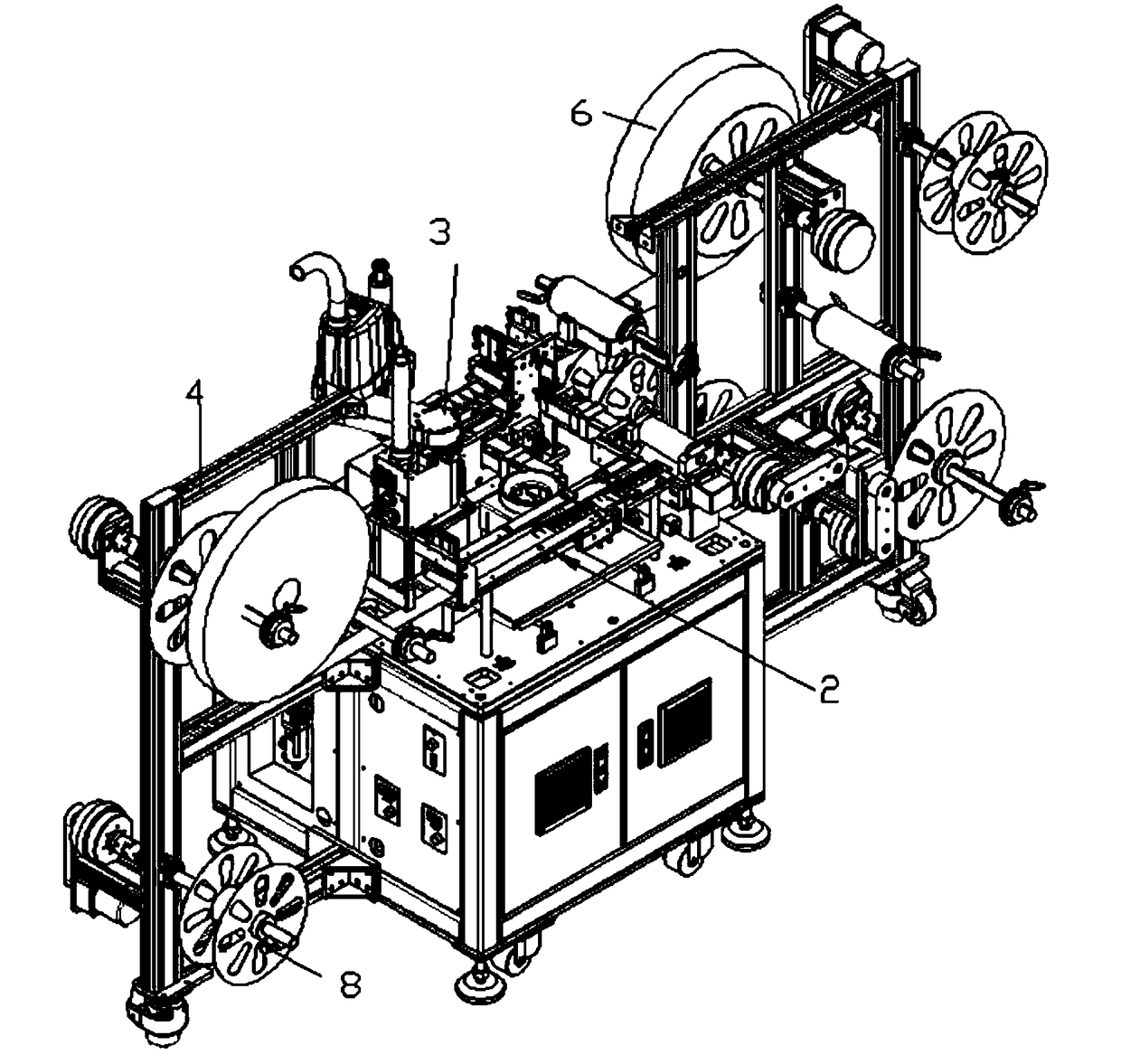

[0014] See Figure 1 to Figure 4 As shown, a graphite flake feeding machine includes a workbench 1, the workbench 1 is provided with a strip detection device 2, a reclaiming manipulator 3 vertically arranged on the top of the strip detection device 2, and also includes The first support 4, one end of the first support 4 is erected on the workbench 1, and the other end is fixed on the ground, and a material stripping device 5 is also provided below the retrieving manipulator 3, and the material pulling device 5 The input end is in transmission connection with the coiling device 6 , the coiling device 6 is fixed on the second support 7 , and the bottom of the first support 4 is connected with a feeding winding device 8 .

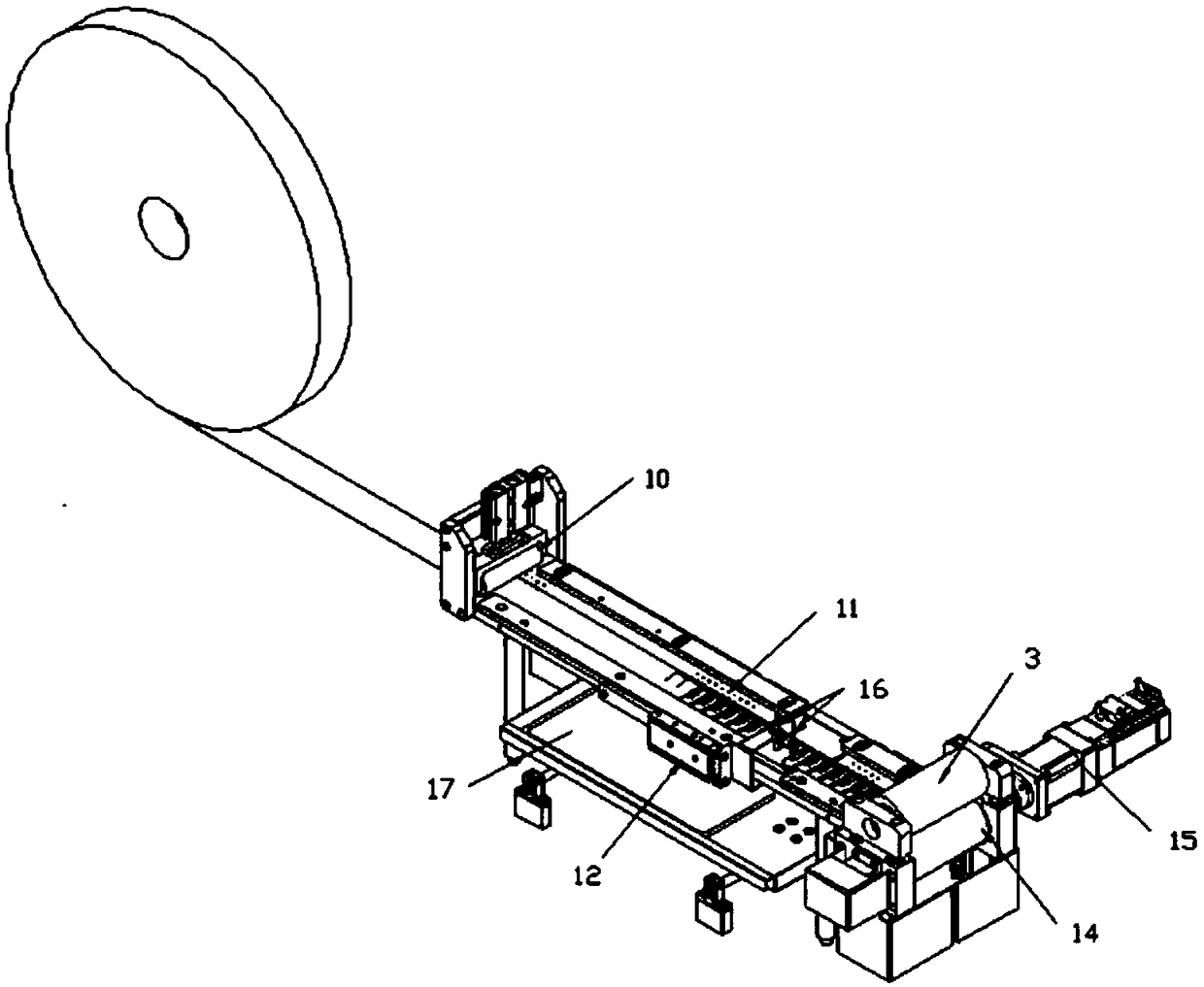

[0015] The output end of the winding device 8 is connected to the input end of the detection assembly line 9, the input portion of the detection assembly line 9 has a pinch roller 10, and the surface of the detection assembly line 9 has a vacuum suction hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com