A double-head cutting device with mechanical synchronous chip removal

A technology of mechanical synchronization and cutting device, which is used in grinding machine parts, grinding/polishing safety devices, grinding racks, etc. , to achieve the effect of increasing integrity and aesthetics, increasing service life, and increasing cutting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

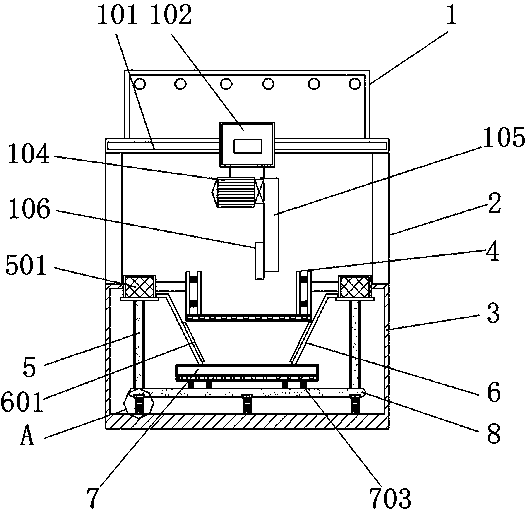

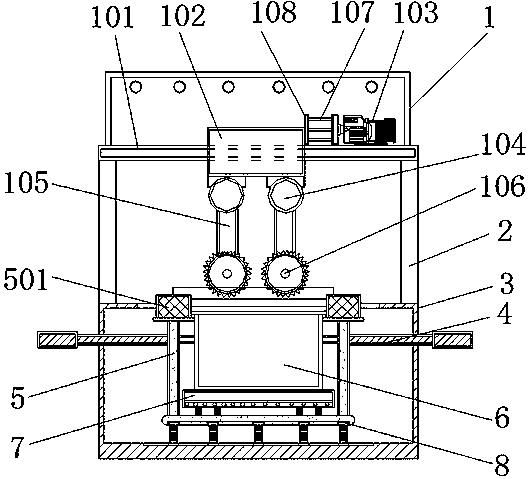

[0030] Embodiment 2, a double-head cutting device with mechanical synchronous chip removal, including a device main body 1, a column 2, a protective cover 3, a workbench 4, a support column 5, a deflector 6, a waste chip collection tank 7 and a limit plate 8. There is a device main body 1 above the protective cover 3, and the device main body 1 is connected to the protective cover 3 through the column 2. The hydraulic cylinder 103 is fixed on the device main body 1. The output end of the hydraulic cylinder 103 is connected with a hydraulic rod 107, and the hydraulic rod The other end of 107 is connected with push plate 108 , and push plate 108 is connected with sliding installation block 102 . The hydraulic cylinder 103 drives the hydraulic rod 107 to expand and contract, thereby driving the sliding mounting block 102 to move along the sliding rod 101 through the push plate 108, which is convenient for cutting the steel to be processed.

[0031] The lower part of the sliding m...

Embodiment 3

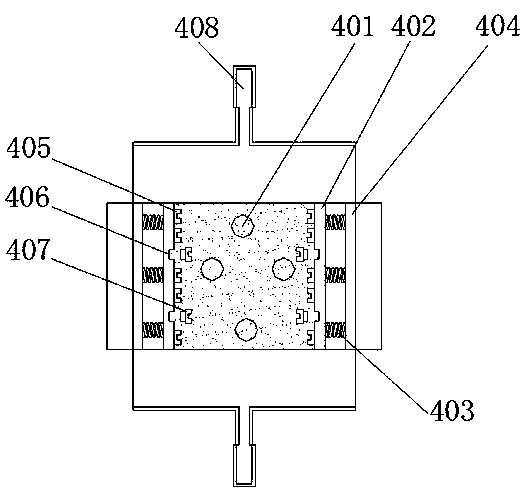

[0032]Embodiment 3, a double-head cutting device with mechanical synchronous chip removal, the two ends of the workbench 4 are provided with limit rods 408, the limit rods 408 pass through the protective cover 3 and cooperate with the protective cover 3, the limit rods 408 can be Sliding relative to the protective cover 3, the ends of the two limit rods 408 are provided with stoppers to limit the position, which ensures the level of the workbench 4 and prevents the processing of steel from being affected. The bottom of the workbench 4 is provided with a base plate, and the base plate is provided with a waste chip collection hole 401, and the waste chips generated in the process flow out through the waste chip collection hole 401, and four waste chip collection holes 401 are evenly and symmetrically arranged to ensure that waste during processing Chips flow down smoothly. Both sides of the base plate of the workbench 4 are provided with spring bases 404, the base plates of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com