Intelligent PCB chip cleaning system

A cleaning system and PCB board technology, applied in the cleaning/polishing of conductive graphics, secondary treatment of printed circuits, electrical components, etc., can solve the problems of air pollution in the workshop, dust spread, and inability to effectively remove dust, etc., and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

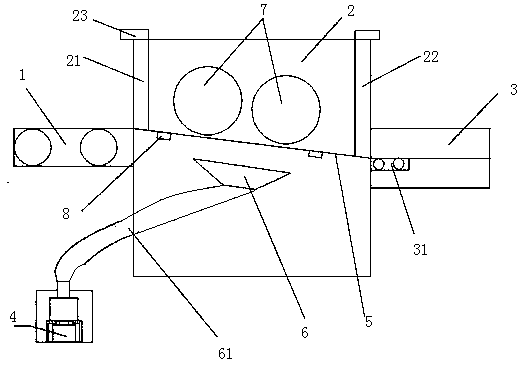

[0016] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0017] Such as figure 1 As shown, the present invention provides an intelligent PCB chip cleaning system, including a conveyor belt 1, a dust removal box 2, a storage box 3 and a dust collection box 4, and the conveyor belt 1 and the dust collection box 4 are located outside the dust removal box 2 The left side of the dust removal box 2 is provided with a first opening 21 for the passage of the PCB board, and the right side of the dust removal box 2 is provided with a second opening 22 for the passage of the PCB board; the conveyor belt 1 conveys the PCB board to the first opening 21 One side of the storage box 3 is connected to the second opening 22, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com