High-safety diaphragm material and its preparation method and application

A high-safety, diaphragm material technology, applied in structural parts, electrical components, battery pack parts, etc., can solve problems such as battery performance degradation, improve heat resistance, improve ion transport characteristics, and improve anti-overcharge performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

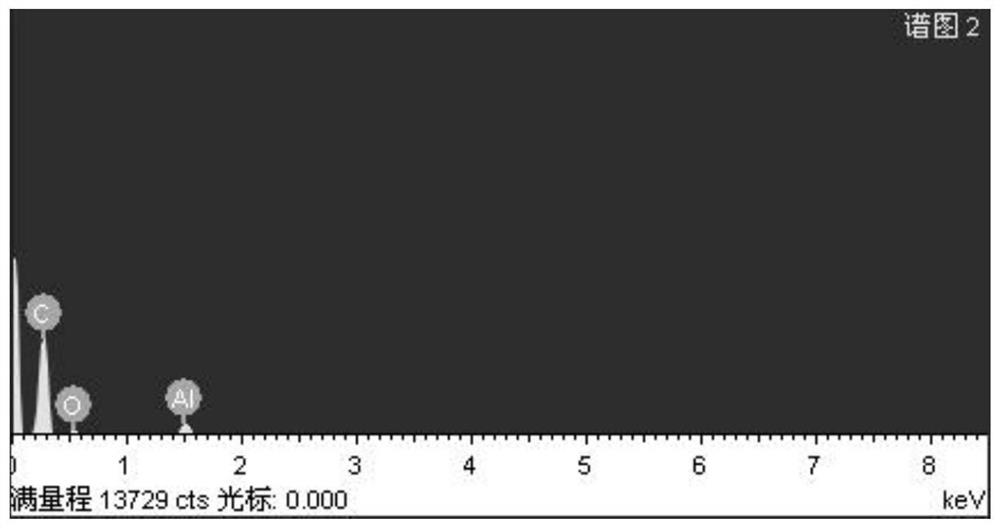

[0026] Example 1. Immerse the polyethylene microporous diaphragm in absolute ethanol, clean it under ultrasonic conditions for 30 minutes, take out the microporous diaphragm, rinse it with absolute ethanol three times, and dry it under vacuum at 60°C for later use. The pretreated PE microporous diaphragm is placed in the reaction chamber of the atomic layer deposition equipment, the chamber is closed, and the reaction chamber is cleaned with high-purity nitrogen with a purity of 99.999%. Use a vacuum pump to pump the reaction chamber to a low vacuum of 10hPa and heat it to 120°C. Under the condition of a carrier gas flow rate of 2ml / min, pass trimethylaluminum into the reaction chamber for 0.1s, and clean it with high-purity nitrogen for 10s to remove excess Trimethylaluminum, then pass in water vapor for 0.2s to hydrolyze the trimethylaluminum, and finally wash with high-purity nitrogen for 20s to remove unreacted water vapor. Repeatedly completing 50 deposition cycles in th...

Embodiment 2

[0032] Example 2. Immerse the microporous non-woven diaphragm of vinylidene fluoride-hexafluoropropylene copolymer in absolute ethanol, clean it under ultrasonic conditions for 30 minutes, take out the microporous diaphragm, rinse it with absolute ethanol three times, and dry it under vacuum at 60°C spare. The pretreated PVDF microporous non-woven diaphragm is placed in the reaction chamber of the atomic layer deposition equipment, the chamber is closed, and the reaction chamber is cleaned with high-purity nitrogen with a purity of 99.999%. Evacuate the reaction chamber to a low vacuum of 20hPa with a vacuum pump and heat it to 140°C. Under the condition of a carrier gas flow rate of 1ml / min, pass aluminum triisopropoxide into the reaction chamber for 0.5s, and clean it with high-purity nitrogen for 5s to remove The excess aluminum triisopropoxide is then fed with water vapor for 1 second to hydrolyze the aluminum triisopropoxide, and finally cleaned with high-purity nitrogen...

Embodiment 3

[0036] Example 3. Immerse the PE / PP / PE three-layer microporous diaphragm in absolute ethanol, clean it under ultrasonic conditions for 30 minutes, take out the microporous diaphragm, rinse it with absolute ethanol three times, and dry it under vacuum at 60°C for later use. Place the pretreated PE / PP / PE microporous diaphragm in the reaction chamber of the atomic layer deposition equipment, close the chamber, and then clean the reaction chamber with high-purity nitrogen with a purity of 99.999%. Use a vacuum pump to pump the reaction chamber to a low vacuum of 10hPa and heat it to 100°C. Under the condition of a carrier gas flow rate of 5ml / min, pass tetraethyl titanate into the reaction chamber for 0.1s, and clean it with high-purity nitrogen for 5s to remove The excess tetraethyl titanate was then fed with water vapor for 0.2s to hydrolyze the tetraethyl titanate, and finally cleaned with high-purity nitrogen for 10s to remove unreacted water vapor. In this way, 100 depositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com