Processing method based on pre-correctable touch film processing equipment

A technology of processing equipment and processing methods, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of waste of manpower and material resources, high production costs, and difficult control of yield, and avoid disconnection. , to ensure the effect of precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

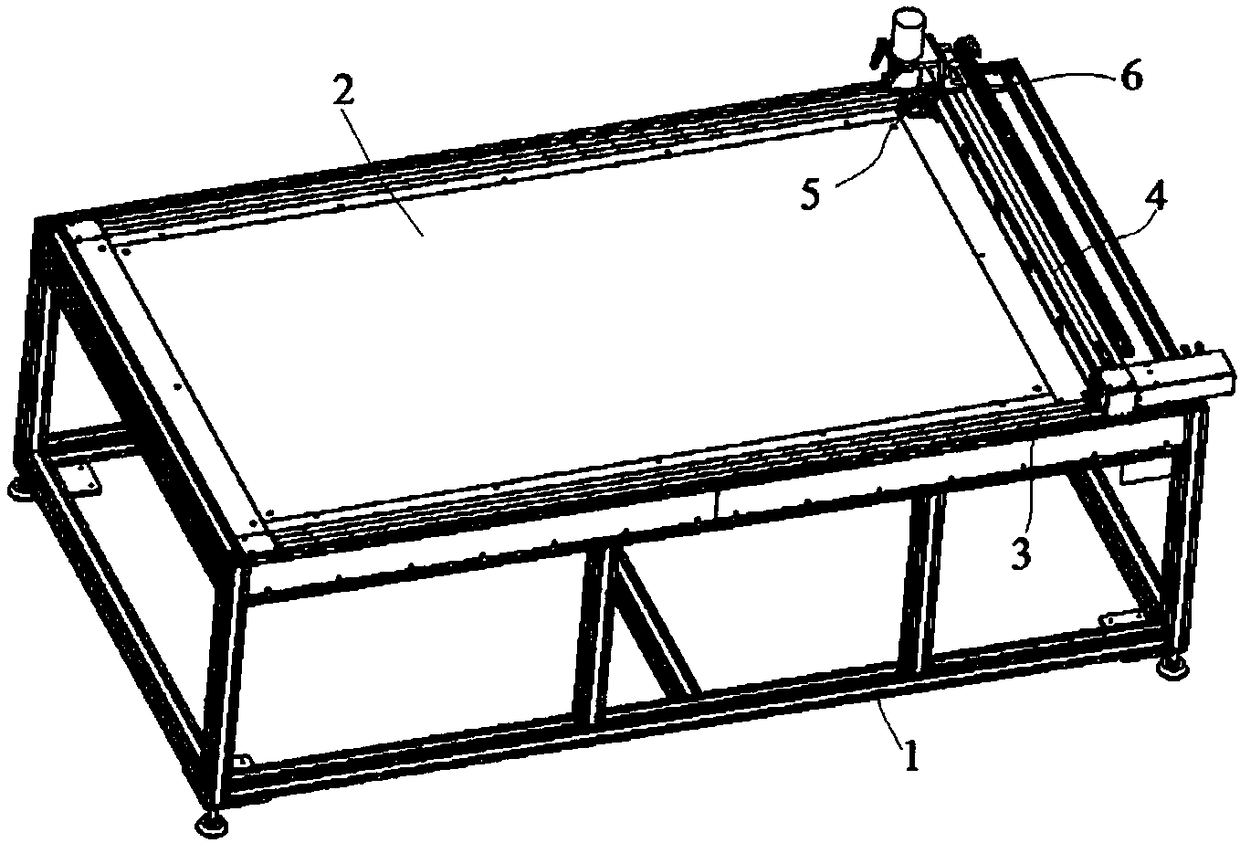

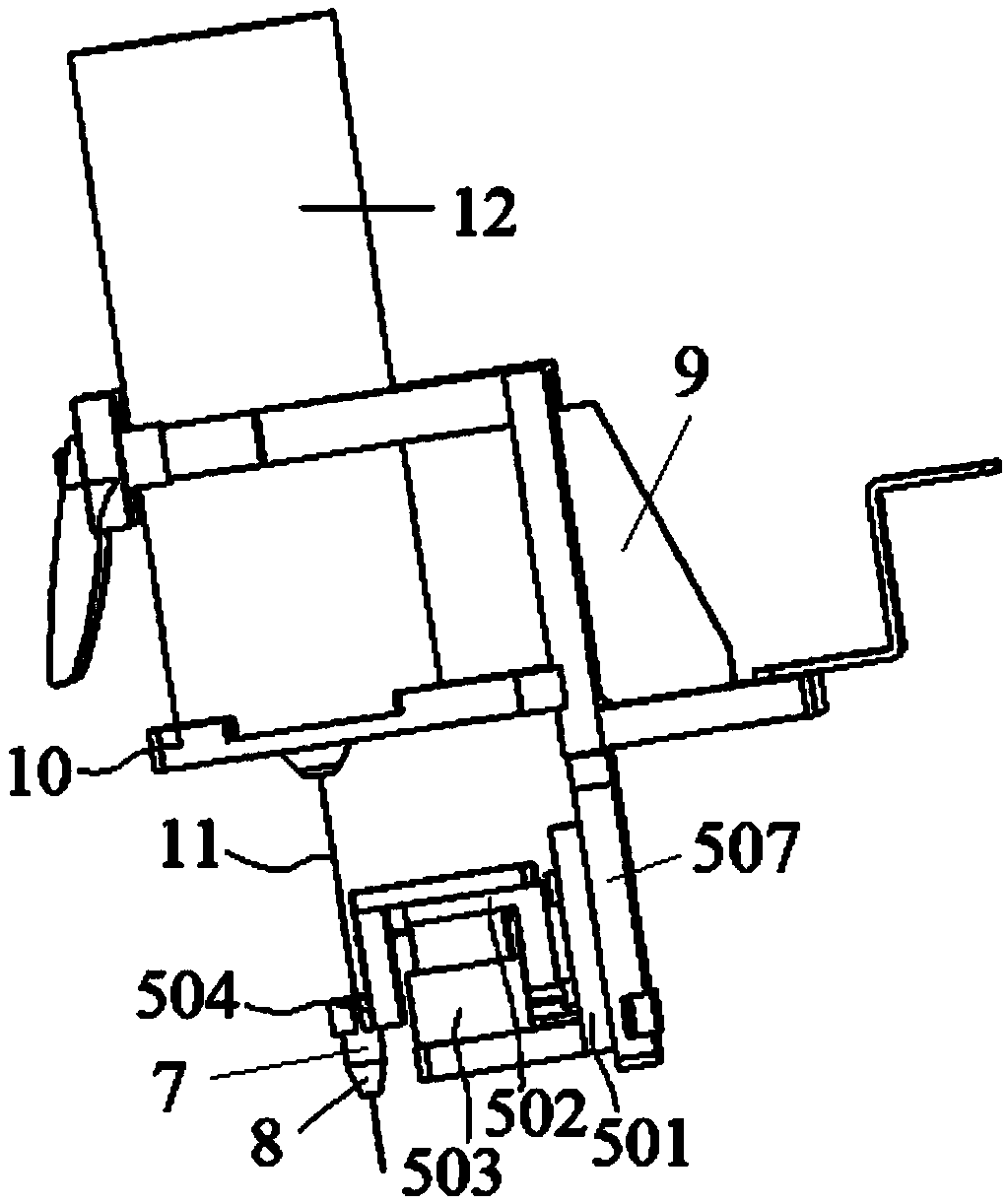

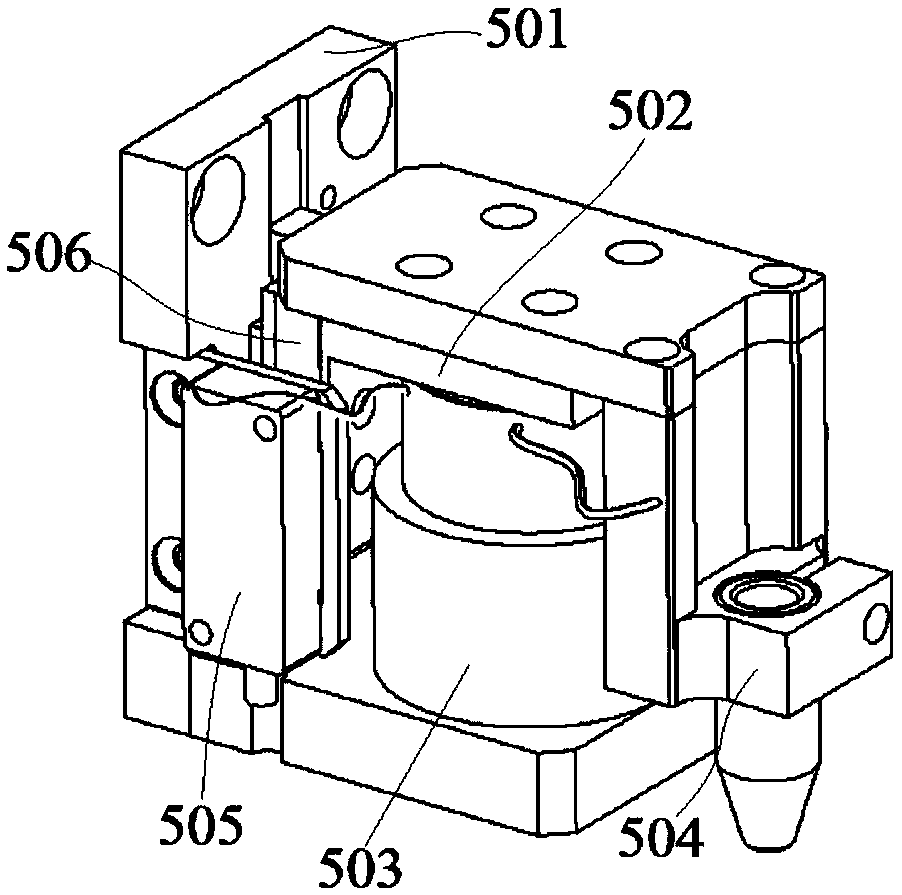

[0038] Embodiment 1: A processing method based on a pre-correctable touch film processing equipment, the processing method is based on a pre-correctable touch film processing equipment, the pre-correctable touch film processing equipment includes a frame 1 , work panel 2, X-axis drive mechanism 3, Y-axis drive mechanism 4 and Z-axis mechanism 5, the work panel 2 is horizontally installed on the frame 1, and the X-axis drive mechanism 3 is installed on the frame 1, so The Y-axis driving mechanism 4 is movably installed on the X-axis driving mechanism 3, and the Z-axis mechanism 5 is movably connected with the Y-axis driving mechanism 4 through a mounting plate 6. The Z-axis mechanism 5 has a testing state and a processing state. When the Z-axis mechanism 5 is in the testing state, a test head 7 is movably installed on the Z-axis mechanism 5, and when the Z-axis mechanism 5 is in the processing state, a printing nozzle 8 is movably installed on the Z-axis mechanism 5;

[0039] T...

Embodiment 2

[0052] Embodiment 2: A processing method based on a pre-correctable touch film processing equipment, the processing method is based on a pre-correctable touch film processing equipment, the pre-correctable touch film processing equipment includes a frame 1 , work panel 2, X-axis drive mechanism 3, Y-axis drive mechanism 4 and Z-axis mechanism 5, the work panel 2 is horizontally installed on the frame 1, and the X-axis drive mechanism 3 is installed on the frame 1, so The Y-axis driving mechanism 4 is movably installed on the X-axis driving mechanism 3, and the Z-axis mechanism 5 is movably connected with the Y-axis driving mechanism 4 through a mounting plate 6. The Z-axis mechanism 5 has a testing state and a processing state. When the Z-axis mechanism 5 is in the testing state, a test head 7 is movably installed on the Z-axis mechanism 5, and when the Z-axis mechanism 5 is in the processing state, a printing nozzle 8 is movably installed on the Z-axis mechanism 5;

[0053] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com