Laser radar

A laser radar and laser technology, applied in the field of radar, can solve the problems of reducing the heat dissipation effect of the laser emission board, low space utilization, complex process, etc., to avoid local high temperature burning components, improve heat dissipation efficiency and performance, and flexible structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

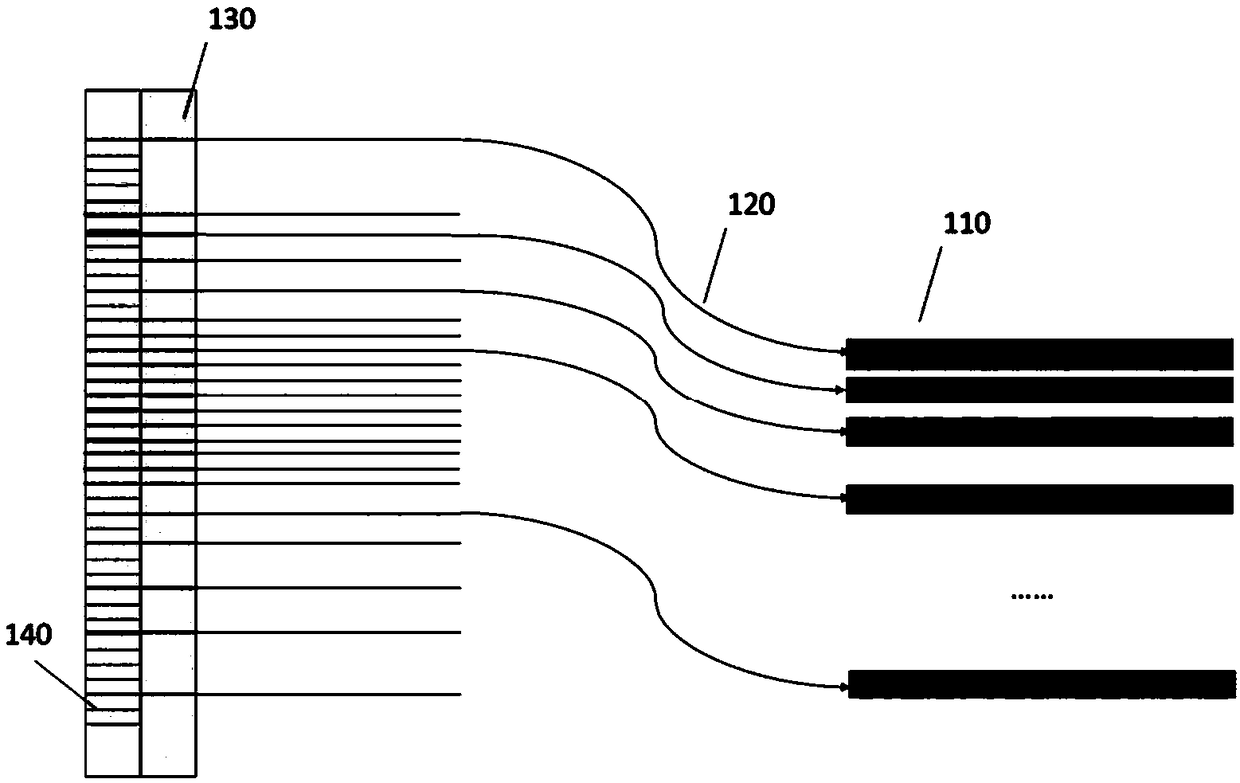

[0070] In a possible embodiment, a light emitting angle control device is provided, such as figure 1 As shown, the device includes a laser light source 110 , a first number of outgoing optical fibers 120 , and an optical fiber holder 130 . The laser beam emitted by the laser light source 110 is coupled to the outgoing optical fiber 120 .

[0071] The fiber holder 130 has a first surface on which a second number of fiber fixing grooves 140 are arranged, and the outgoing optical fiber 120 is fixed in the fiber fixing grooves 140 and passes through the first surface , and the outgoing end face of the outgoing optical fiber 120 passes through the optical fiber fixing groove 140 .

[0072] The outgoing end face of the outgoing optical fiber 120 and the fiber fixing groove 140 are configured to converge the light beam exiting the optical fiber end face according to a specified angle.

[0073] The laser light source 110 is a laser emitting board equipped with multiple lasers, and t...

Embodiment 2

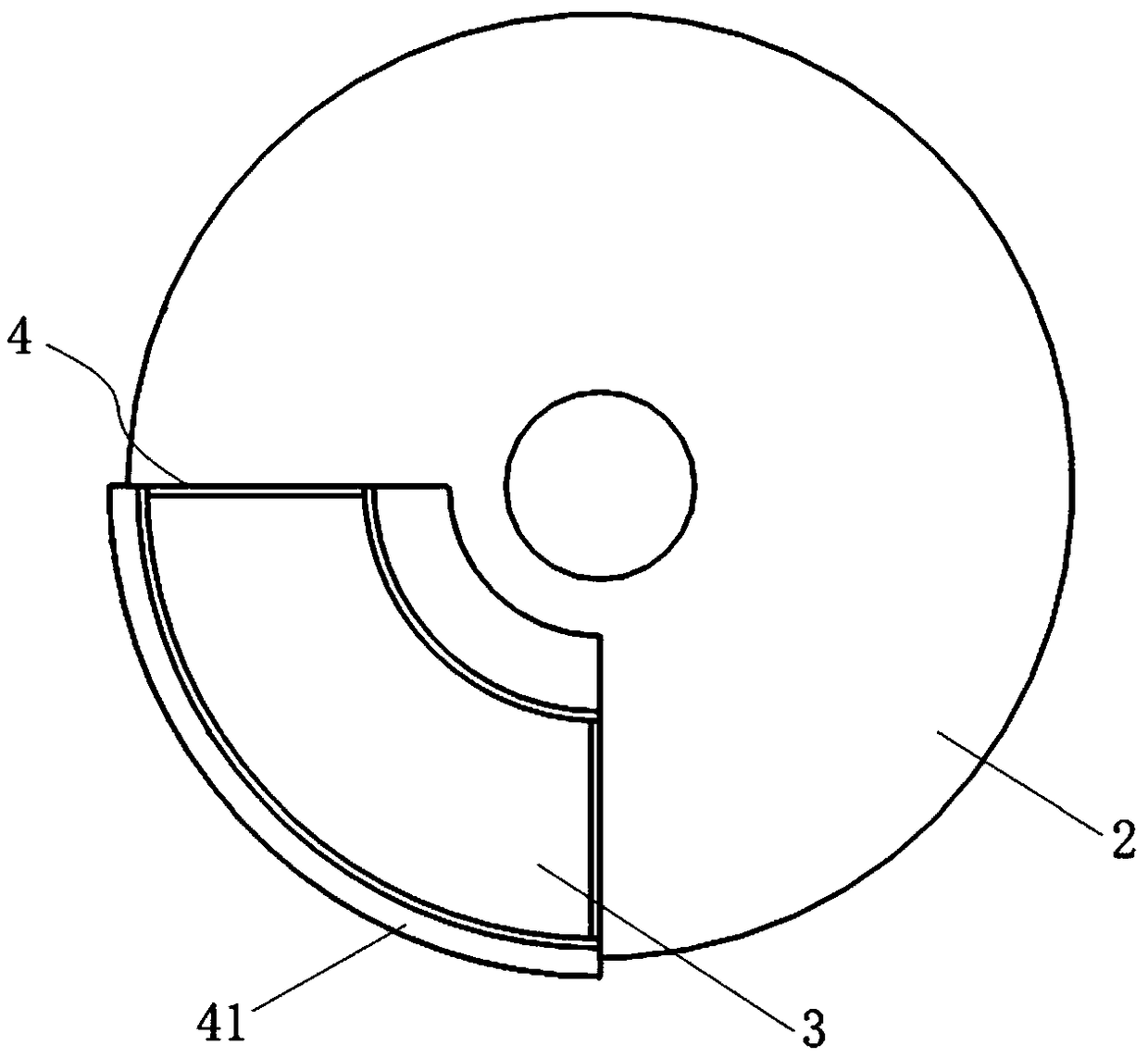

[0105] combine figure 2 , image 3 as well as Figure 20 to Figure 22 , a high-line-number laser radar, including a rotor, a laser emitting device, and an exit lens group,

[0106] The rotor has an emitting cavity and a receiving cavity isolated from each other;

[0107] The laser emitting device is used to emit detection light to the target object;

[0108] The outgoing lens group is used to emit the received detection light to the detection area;

[0109] The laser emitting device includes at least one laser emitting board 3 and a coupling optical fiber, the laser emitting board 3 is arranged in the emitting cavity, and at least one light source for emitting detection light is installed on the laser emitting board 3, so The coupling optical fiber corresponds to the light source one by one, the light source is coupled to the input end of the coupling optical fiber, and the output end of the coupling optical fiber is arranged at the focal plane of the outgoing lens assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com