A fabric wrinkle recovery performance testing device and use thereof

A technology for testing devices and fabrics, applied in measuring devices, adopting mechanical devices, analyzing materials, etc., can solve problems such as large discreteness, poor test stability, and long test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Sample fabric parameters: raw material 100% cotton, plain weave, warp yarn density 41.6tex, weft yarn density 58.3tex, warp density 350, weft density 280.

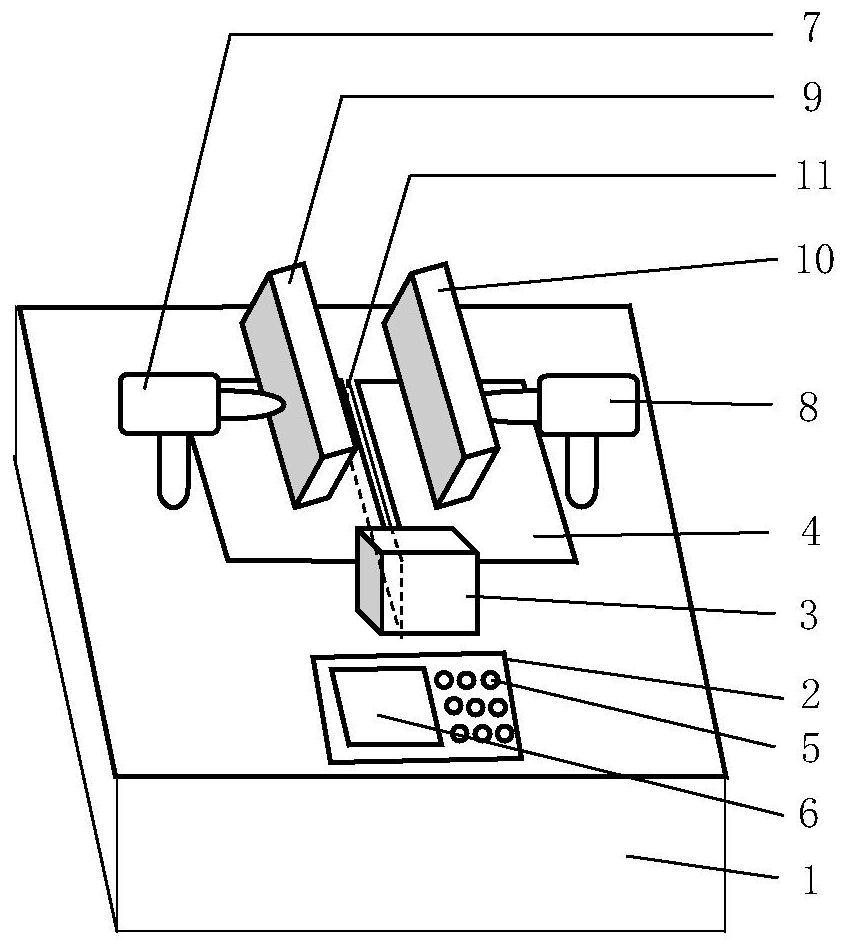

[0023] The steps of testing the sample fabric with the fabric wrinkle recovery performance device of the present invention are as follows:

[0024] Step 1: Select the fabric to be tested with a size of 380mm×380mm, and place the fabric to be tested horizontally on the sample table 4;

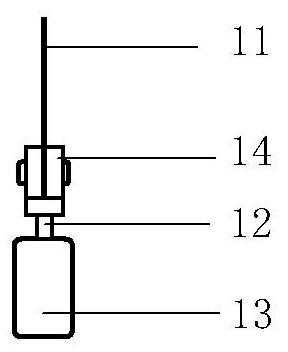

[0025] Step 2: Start the lifter 12, lift the fabric to be tested by 80mm at a rising speed of 0.02m / s through the sheet 11, so that part of the fabric to be tested enters between the left press block 9 and the right press block 10, and passes through the left cylinder 7 And the right cylinder 8 makes the left pressing block 9 and the right pressing block 10 move toward each other at a speed of 0.02m / s, and after contacting the fabric to be tested, apply a pressure of 20N, pressurize for 1min, and then control the left pressing block 9...

Embodiment 2

[0028] Sample fabric parameters: raw material 65% cotton / 35% polyester, two up and one down left twill weave, warp yarn density 58.3tex, weft yarn density 58.3tex, warp density 320, weft density 250.

[0029] The steps of testing the sample fabric with the fabric wrinkle recovery performance device of the present invention are as follows:

[0030] Step 1: Select the fabric to be tested with a size of 380mm×380mm, and place the fabric to be tested horizontally on the sample table 4;

[0031] Step 2: Start the lifter 12, lift the fabric to be tested by 80mm at a rising speed of 0.02m / s through the sheet 11, so that part of the fabric to be tested enters between the left press block 9 and the right press block 10, and passes through the left cylinder 7 And the right cylinder 8 makes the left pressing block 9 and the right pressing block 10 move toward each other at a speed of 0.02m / s, and after contacting the fabric to be tested, apply a pressure of 20N, pressurize for 1min, and ...

Embodiment 3

[0034] Sample fabric parameters: raw material 100% wool, two upper and two lower left twill weaves, warp yarn density 16.6tex, weft yarn density 14.6tex, warp density 345, weft density 300.

[0035] The steps of testing the sample fabric with the fabric wrinkle recovery performance device of the present invention are as follows:

[0036] Step 1: Select the fabric to be tested with a size of 380mm×380mm, and place the fabric to be tested horizontally on the sample table 4;

[0037]Step 2: Start the lifter 12, lift the fabric to be tested by 90mm at a rising speed of 0.02m / s through the sheet 11, so that part of the fabric to be tested enters between the left press block 9 and the right press block 10, and passes through the left cylinder 7 And the right cylinder 8 makes the left pressing block 9 and the right pressing block 10 move towards each other at a speed of 0.02m / s, and after contacting the fabric to be tested, apply a pressure of 25N, pressurize for 1min, and then contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com