A grain sampling device for a grain depot

A technology for sampling and grain, applied in the field of grain-sampling device in grain depots, can solve the problems of small remaining space for grain surface and warehouse roof, unstable grain surface, and inability to cut samples, so as to avoid human hidden dangers and reduce The effect of human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

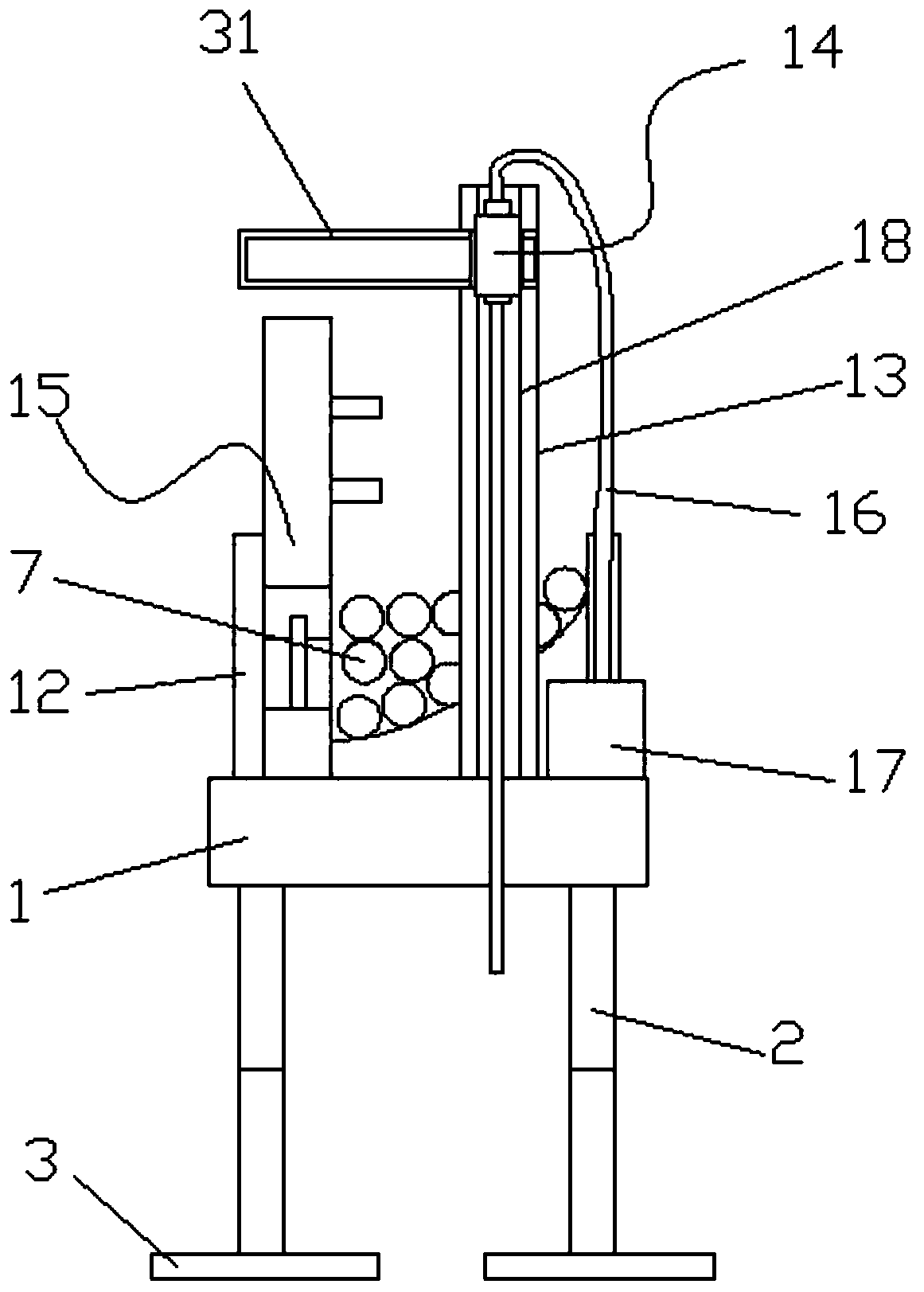

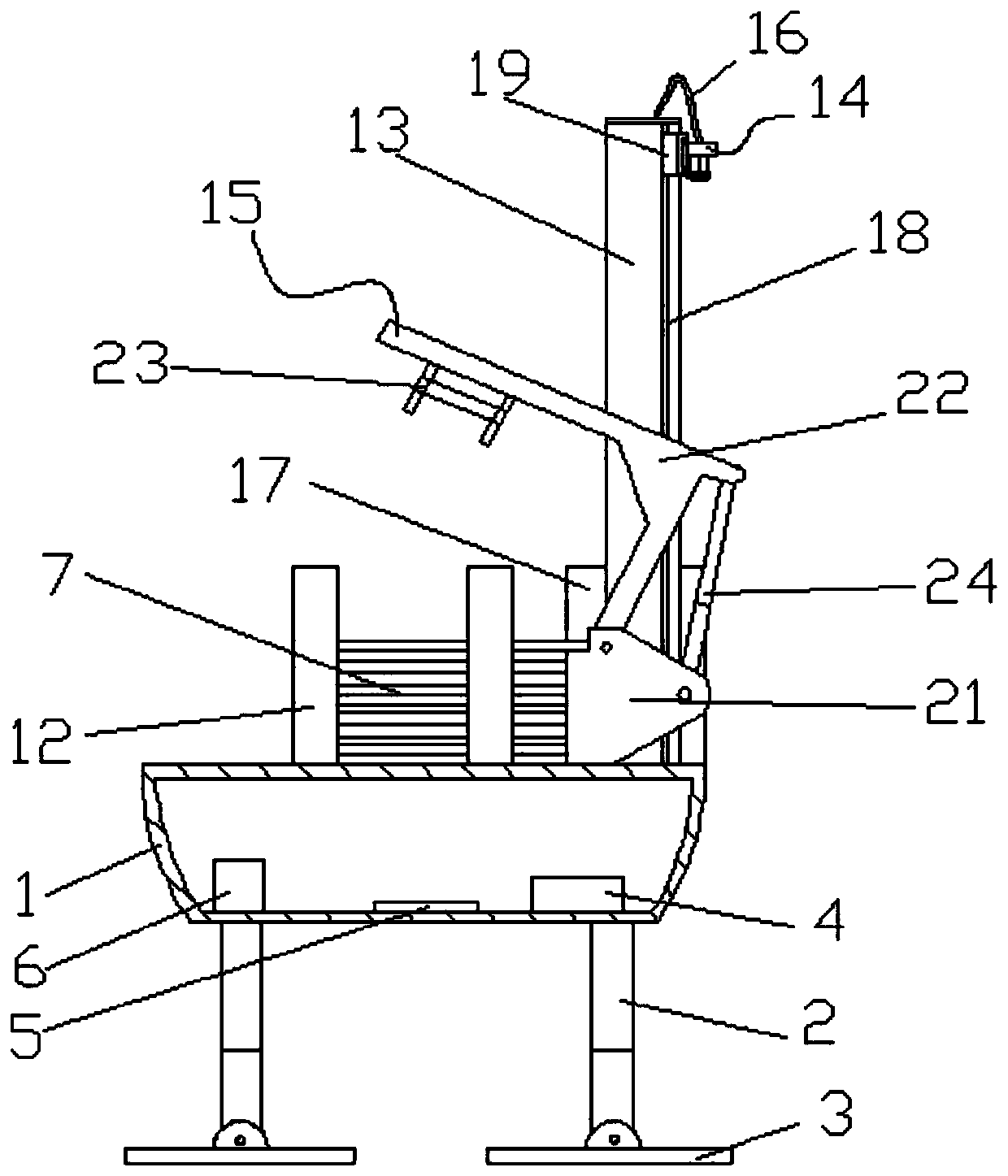

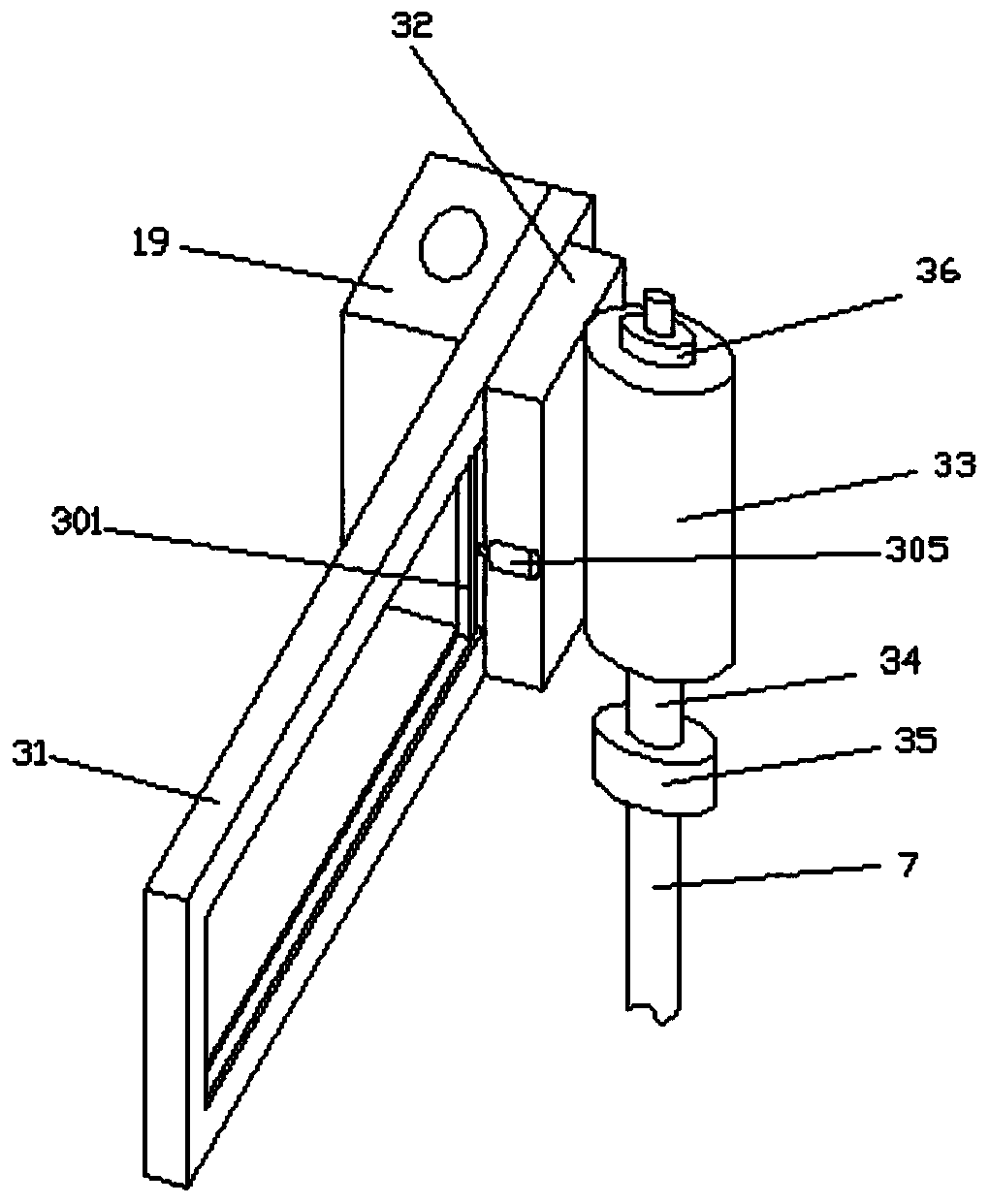

[0028] like figure 1 Shown; A grain depot grain sampling device, comprising a base box 1, a sampling rod 7, four corners of the lower bottom surface of the base box 1 are fixedly installed with four groups of first electric telescopic rods 2 perpendicular to the lower bottom surface, the first The lower end of the electric telescopic rod 2 is hinged with a horizontal backing plate 3, and a controller 4, a level sensor 5 and a battery pack 6 are installed inside the base box 1, and the controller 4 is electrically connected to the level sensor 5 and the first electric telescopic rod 2 and the battery pack. 6. Both sides of the upper surface of the base box 1 are provided with baffles 12, and the sample rod 7 is located on the upper surface of the base box 1 between the baffles 12 on both sides. The front end of the base box 1 is equipped with a column 13 perpendicular to the upper surface. 13 upper end is equipped with inserting rod device 14, and the base box 1 upper surface o...

Embodiment 2

[0032] like figure 1 Shown; A grain depot grain sampling device, comprising a base box 1, a sampling rod 7, four corners of the lower bottom surface of the base box 1 are fixedly installed with four groups of first electric telescopic rods 2 perpendicular to the lower bottom surface, the first The lower end of the electric telescopic rod 2 is hinged with a horizontal backing plate 3, and a controller 4, a level sensor 5 and a battery pack 6 are installed inside the base box 1, and the controller 4 is electrically connected to the level sensor 5 and the first electric telescopic rod 2 and the battery pack. 6. Both sides of the upper surface of the base box 1 are provided with baffles 12, and the sample rod 7 is located on the upper surface of the base box 1 between the baffles 12 on both sides. The front end of the base box 1 is equipped with a column 13 perpendicular to the upper surface. 13 upper end is equipped with inserting rod device 14, and the base box 1 upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com