Method for monitoring dynamic loading capacity of automobile tyre based on wheel-mounted intelligent sensing

A technology of dynamic load and automobile tires, which is applied in the direction of automobile tire testing, vehicle testing, measuring devices, etc., can solve the problems of real-time monitoring of tire dynamic load capacity, unfavorable prediction and evaluation, and inability to effectively obtain tire dynamic load capacity, etc., to achieve Increase the prediction function, ensure tire safety performance, and avoid damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

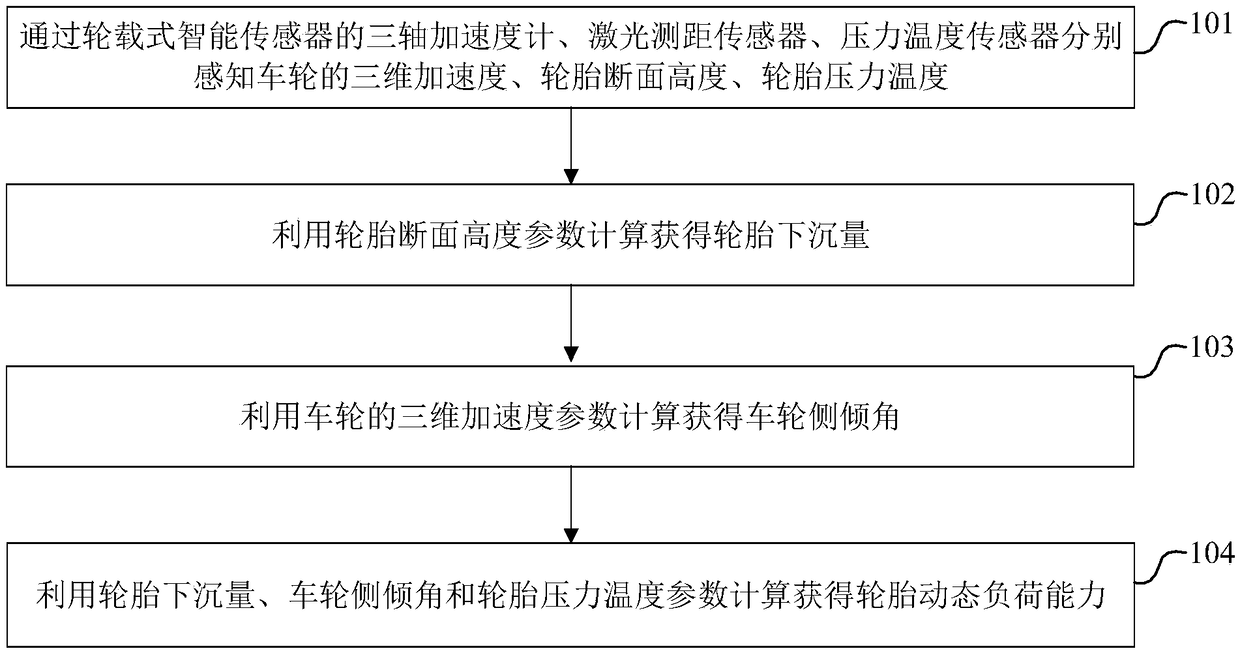

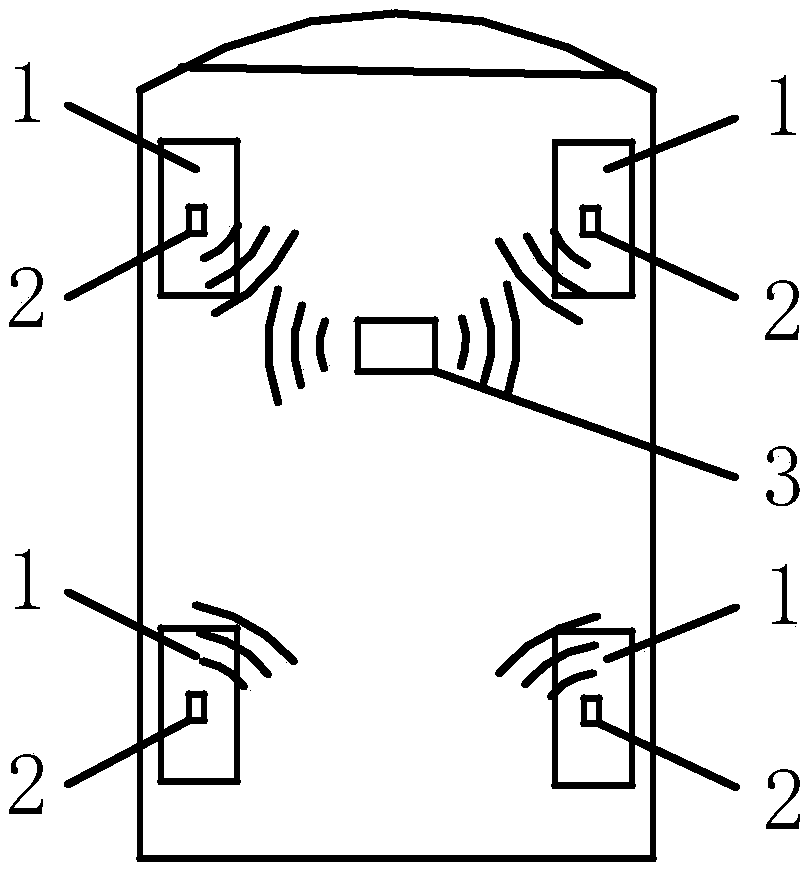

[0022] Such as figure 1 As shown, it is a method for monitoring the dynamic load capacity of automobile tires based on wheel-mounted intelligent sensors, and the method includes the following steps:

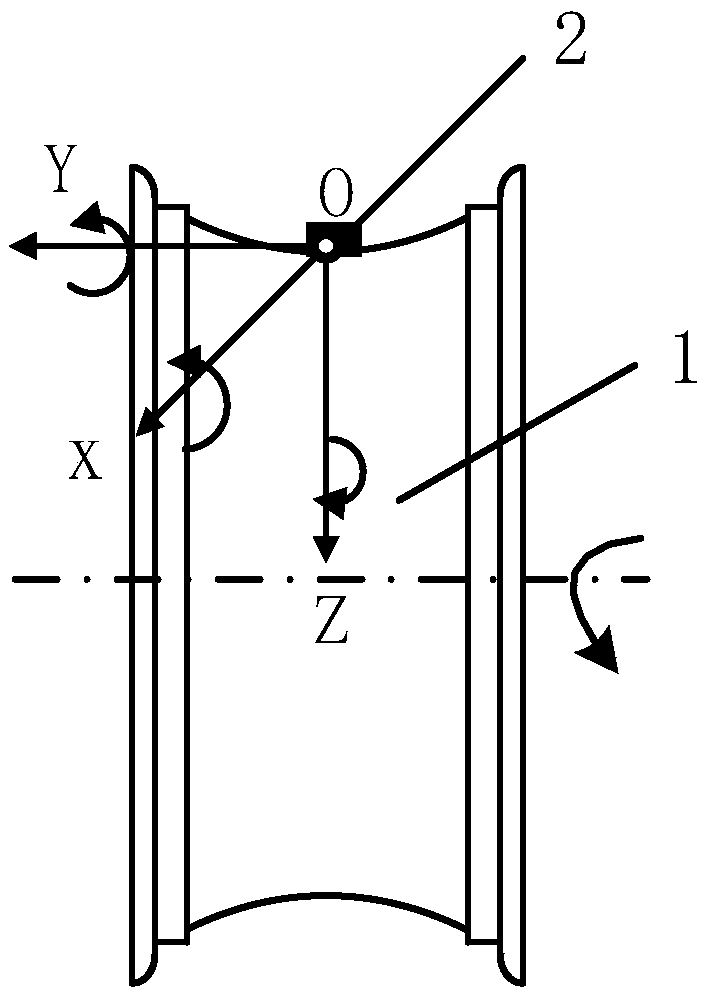

[0023] Step 101 senses the three-dimensional acceleration of the wheel, the height of the tire section, and the pressure and temperature of the tire through the three-axis accelerometer of the wheel-mounted smart sensor, the laser ranging sensor, and the pressure and temperature sensor;

[0024] Step 102 calculates and obtains the tire sinkage by using the tire section height parameter;

[0025] Step 103 calculates and obtains the wheel roll angle by using the three-dimensional acceleration parameters of the wheel;

[0026] Step 104 calculates and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com