Integrated bearing base capable of accurately detecting bearing working condition

An integrated, bearing seat technology, which is applied to the rigid support of bearing components, bearings, bearing cooling, etc., can solve the problems of bearing temperature data collection, etc., and achieve the effects of improving production efficiency, reducing temperature rise and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

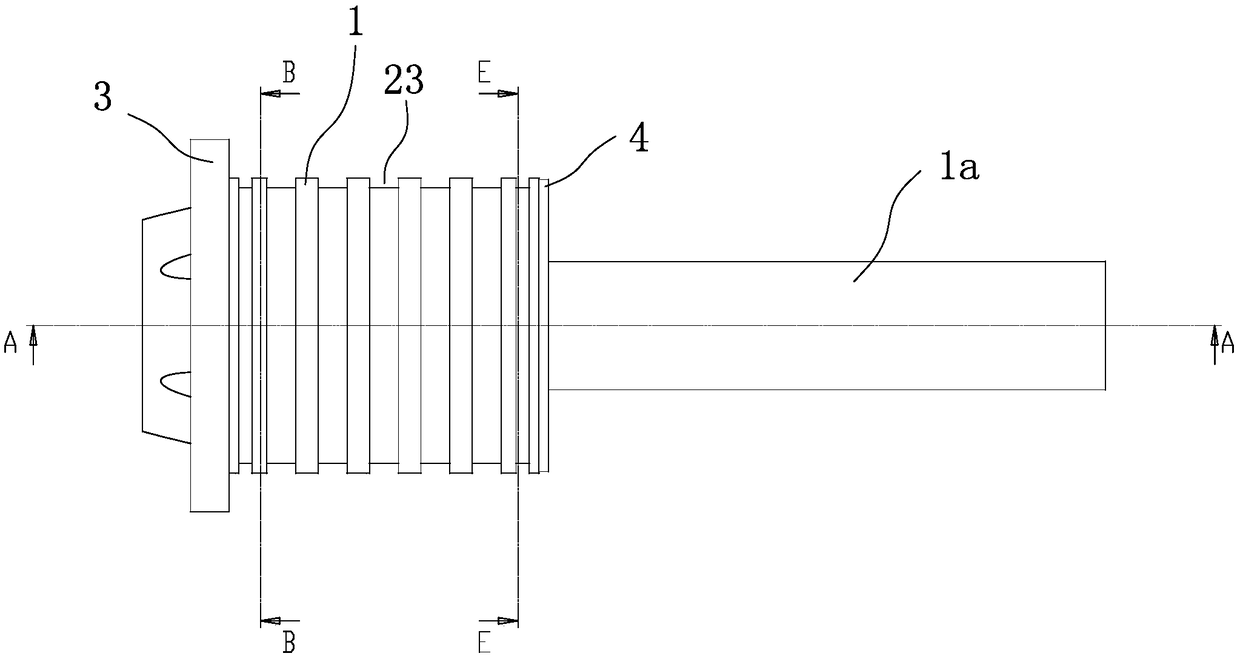

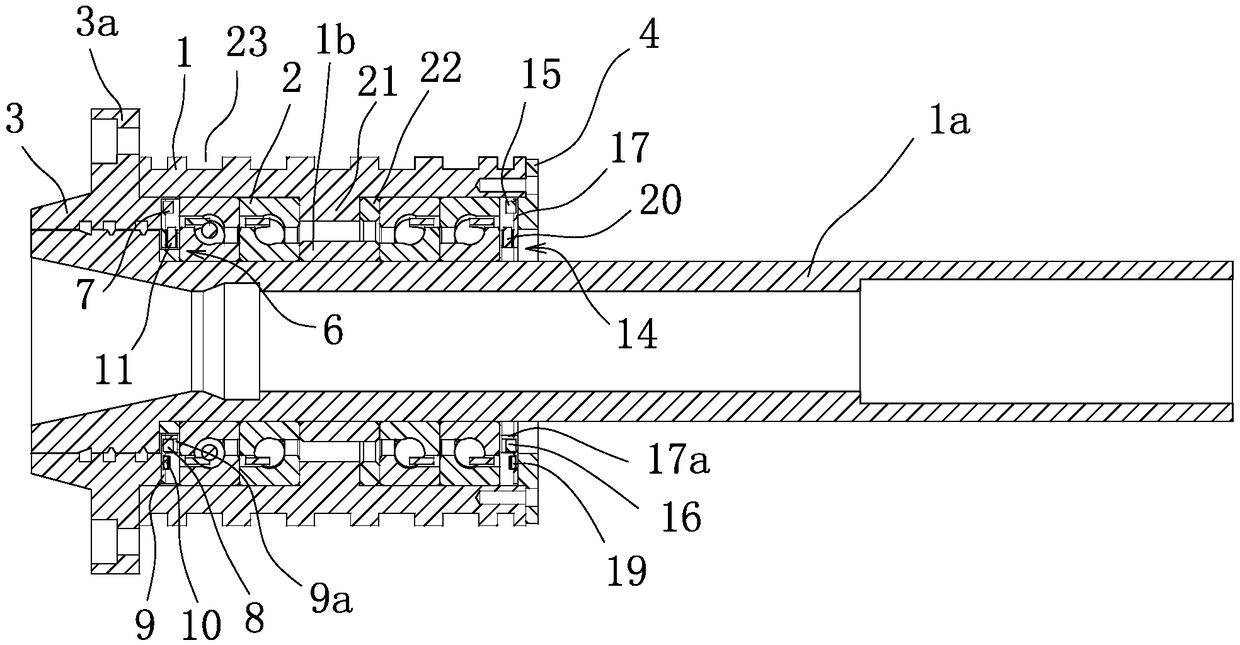

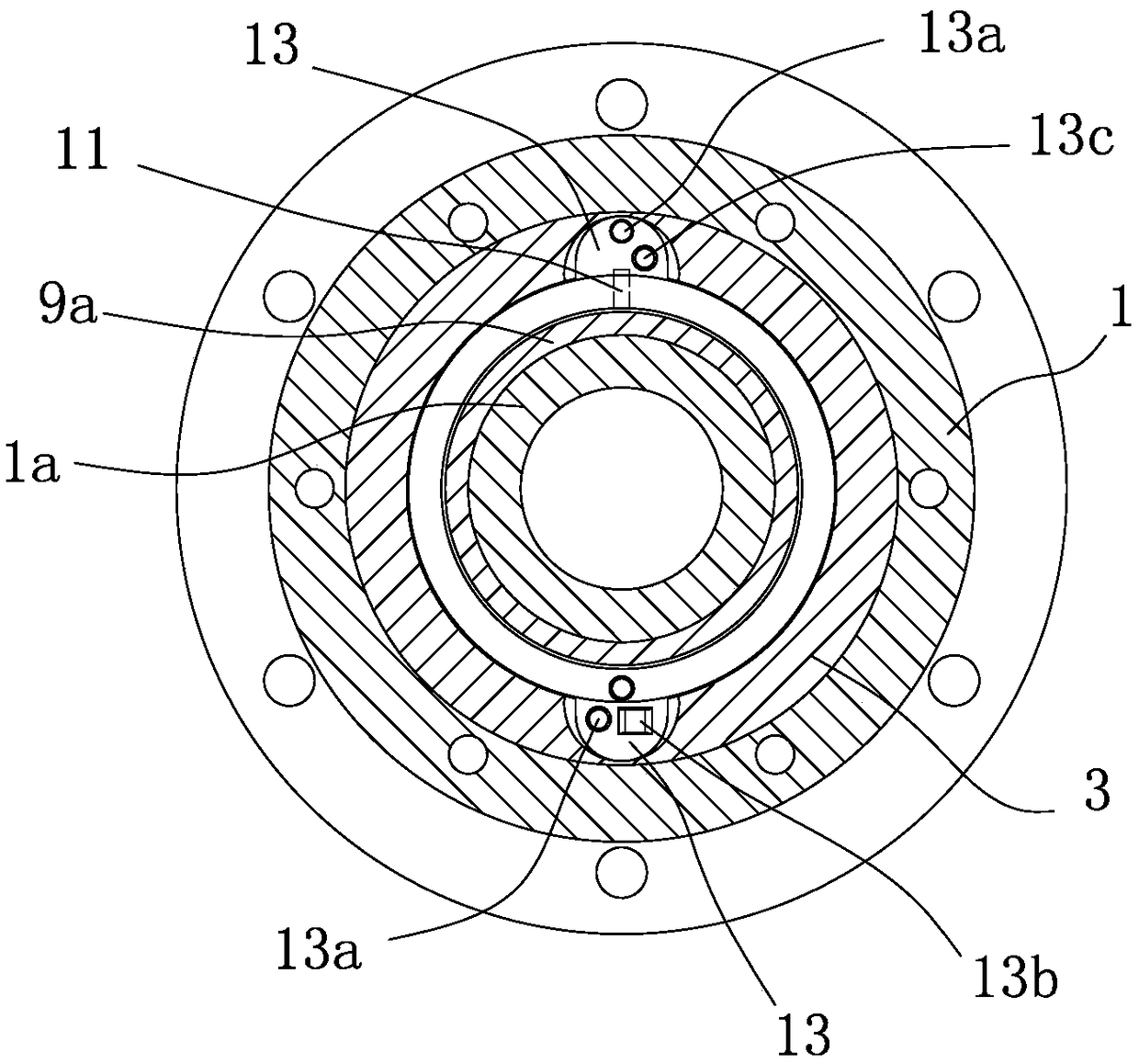

[0035] like figure 1 and Figure 5 As shown, an integrated bearing seat capable of accurately detecting the working condition of the bearing includes a shaft sleeve 1, which is in a cylindrical shape. There are rear end cover 3 and front end cover 4. In this embodiment, the number of bearings 2 is not limited. Those skilled in the art can adjust the number of bearings according to the needs of actual work. The outer ring of the bearing is tightly fitted with the inner wall of the shaft sleeve 1. The snare is arranged on the main shaft 1a and is connected with the main shaft. When the main shaft 1a rotates, the inner ring of the bearing 2 also rotates synchronously. Regarding the connection between the shaft sleeve 1 and the front end cover 4 and the rear end cover 3, methods such as screw connection, pin connection or card connection can be used. This is a common means f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com