A novel flexible shear stress and pressure sensor structure and manufacturing method

A technology of a pressure sensor and a manufacturing method, which is applied in the direction of measuring fluid pressure, fluid pressure measurement through thermal devices, instruments, etc., can solve the problems of reducing measurement sensitivity and accuracy, and achieve high aspect ratio, fast response, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

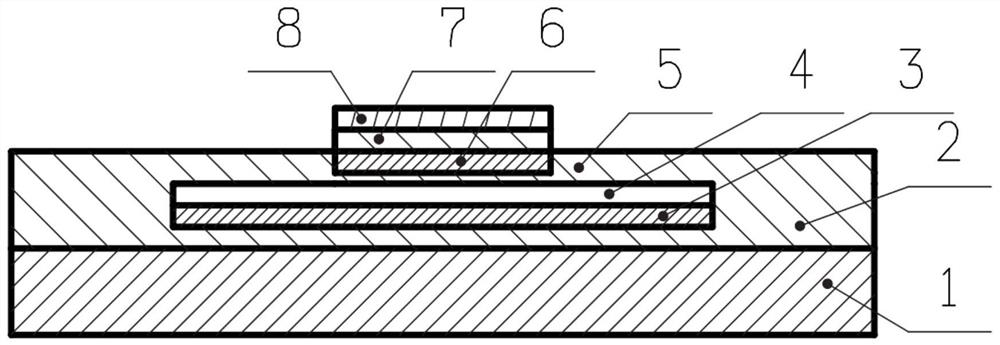

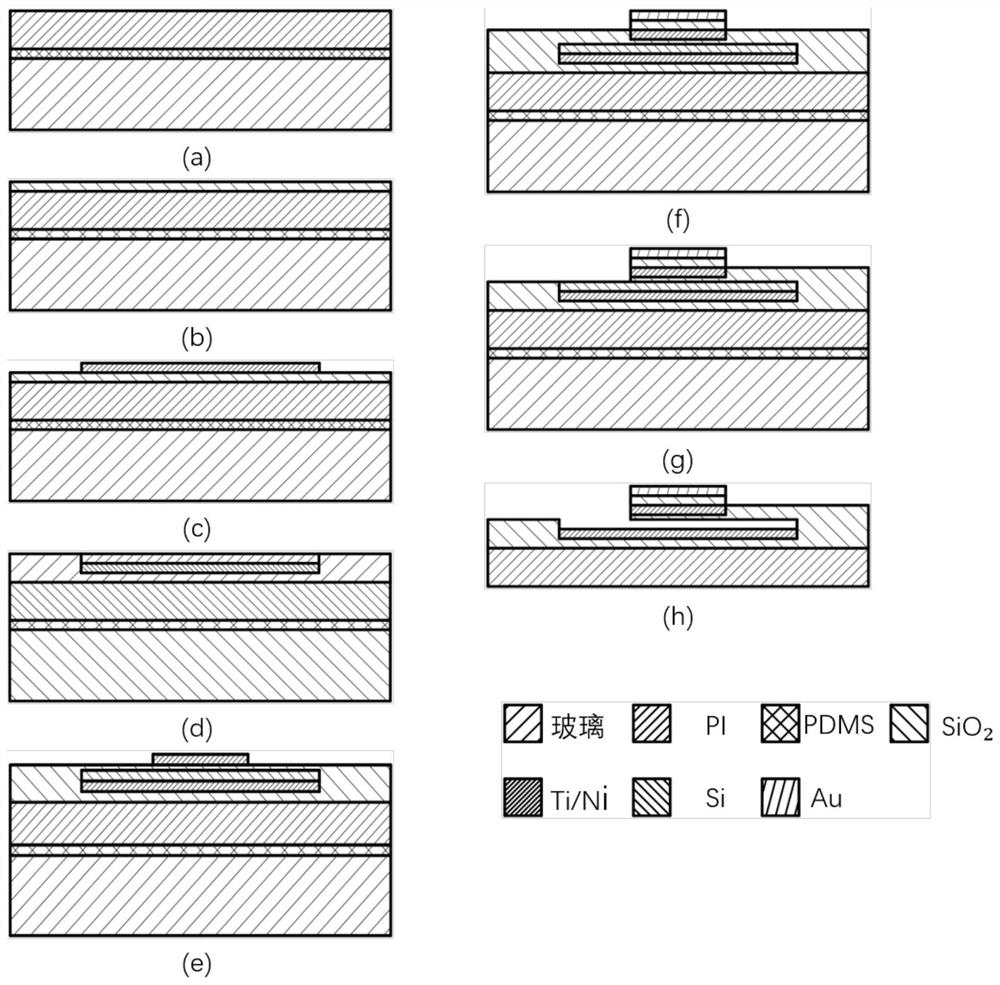

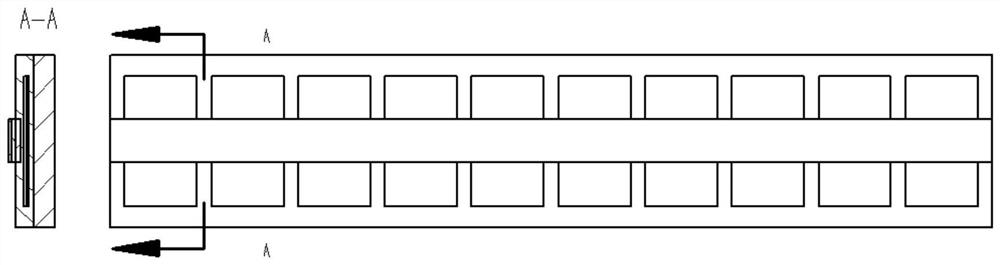

[0030] Refer to figure 1 , image 3 , Figure 4 The new type of flexible shear stress and pressure sensor in this embodiment has a silicon dioxide layer 2 on the PI flexible substrate 1, a cavity 4 in the middle of the silicon dioxide layer 2 with a width of 9 μm; the cavity 4 The upper middle position is the "sandwich" sensitive unit of the sensor. The sensitive unit is the heating unit 8, the silicon dioxide insulating layer 7 and the measuring unit 6 from top to bottom; the materials of the heating unit 8 and the measuring unit 6 in this embodiment They are gold and nickel. The sensitive unit is supported by 100 micron-sized simply supported beams 5 on the upper end of the cavity 4. The length, width and height of the simply supported beams 5 are 9 μm, 1 μm, and 1 μm, respectively. One of the two adjacent simply supported beams 5 The gap between them is 5μm; the two ends of the simply supported beam 5 are fixed on the sidewalls of the cavity 4; the bottom of the cavity 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com