A Linked Industrial Flow Accurate Metering Method

A metering method and flow metering technology, applied in liquid/fluid solid measurement, test/calibration volume flow, measuring devices, etc., can solve the problems affecting the accuracy of industrial flow metering, the decrease of metering accuracy of flowmeters, and unfavorable development of industrial automation, etc. , to achieve the effect of improving accuracy and reliability, reducing measurement deviation and optimizing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

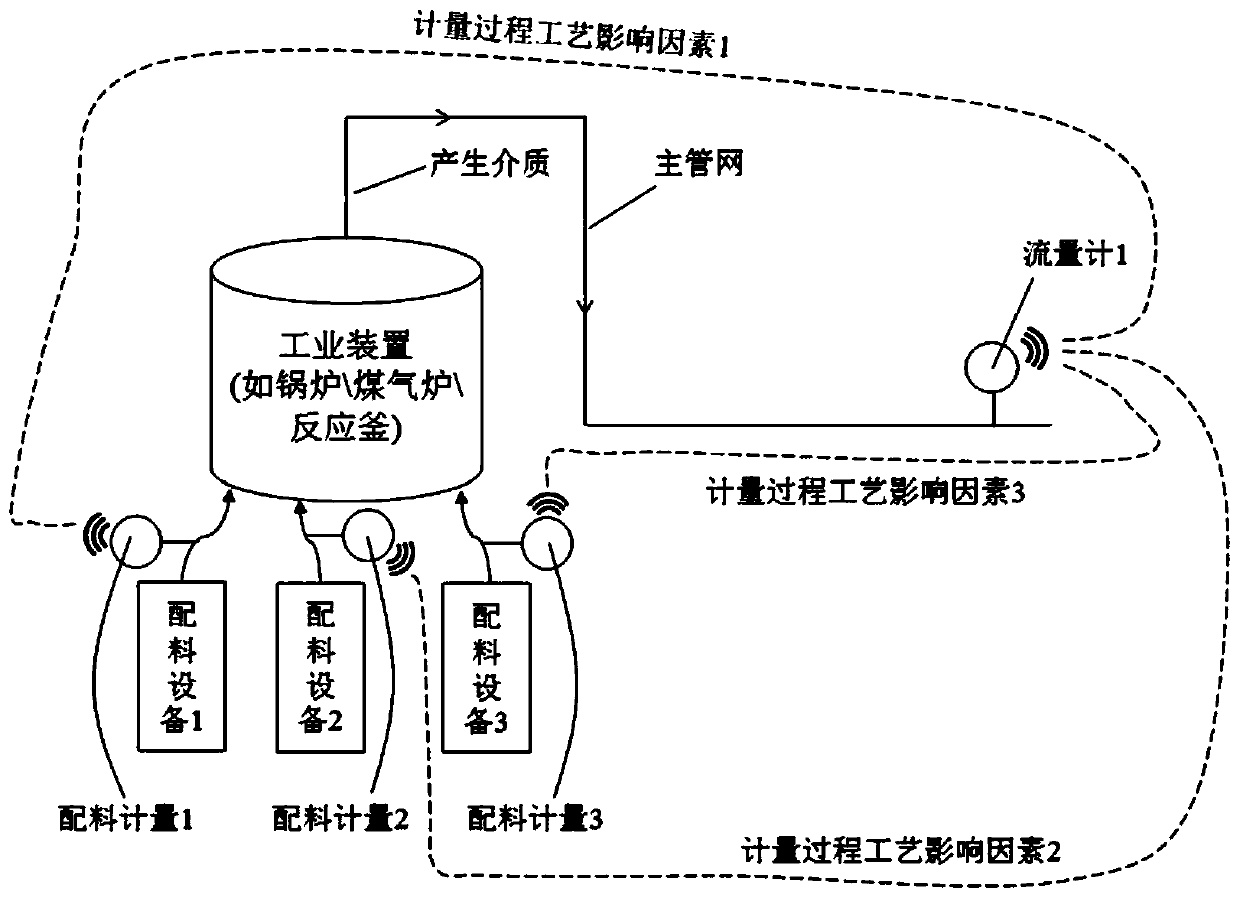

[0059] The specific steps of the present invention are described in detail. The linkage type industrial flow precise measurement method includes:

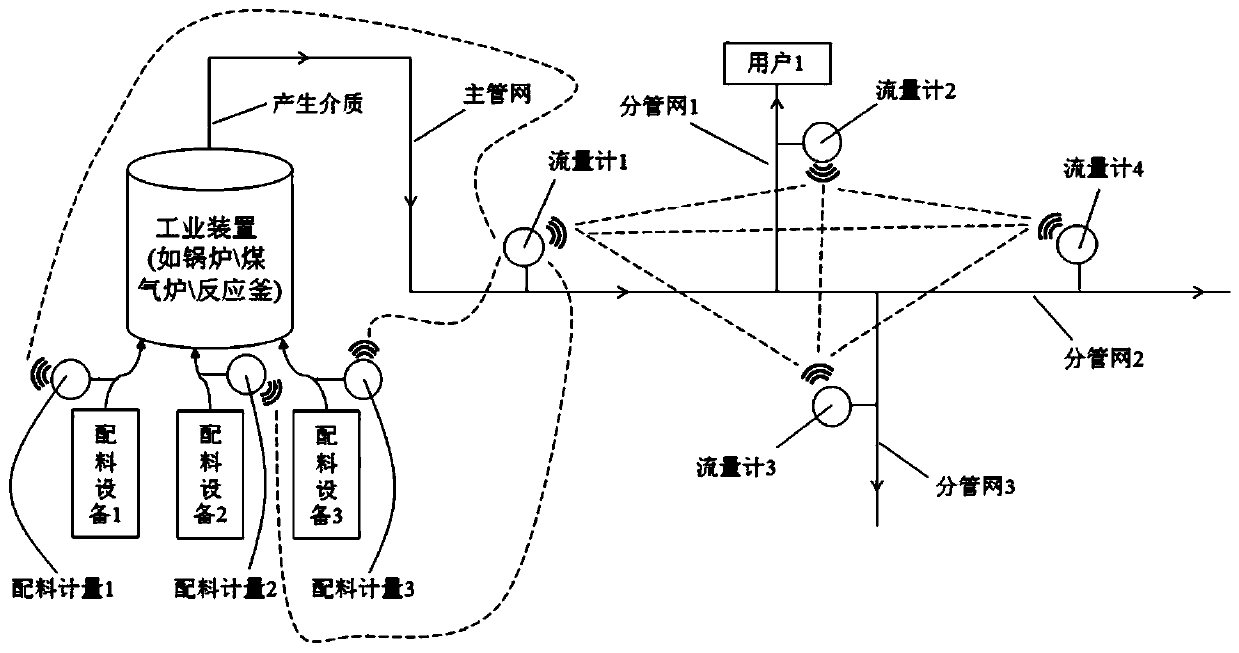

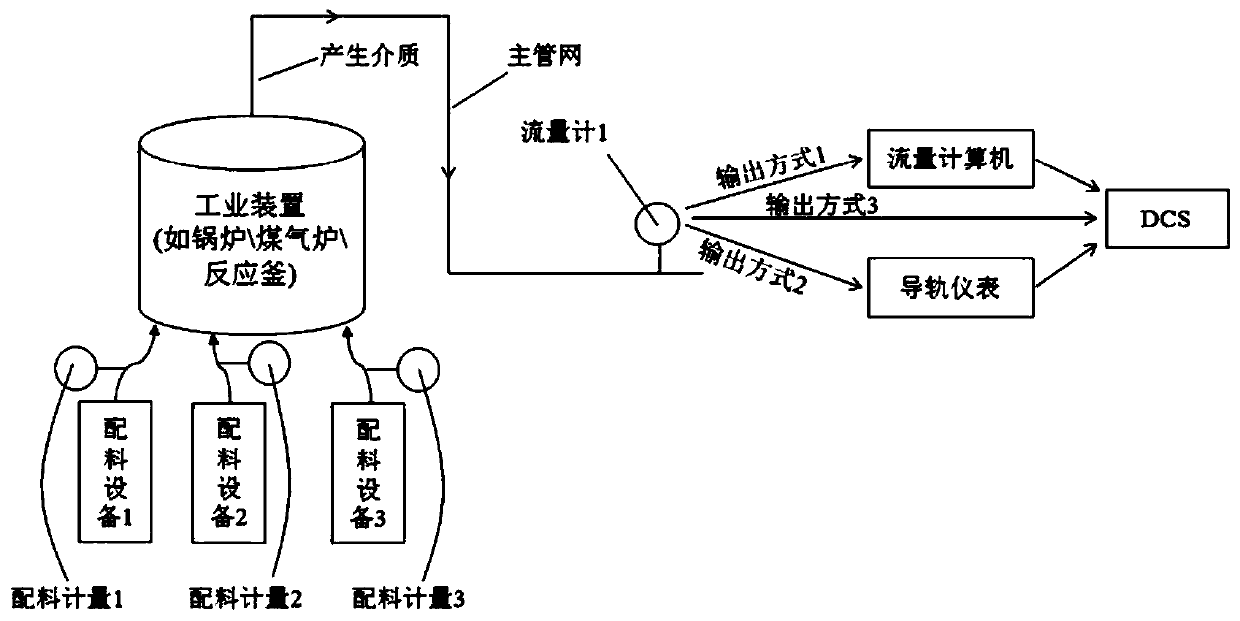

[0060] Step 1. The process algorithm interacts with the measurement process data. The process involved in the method of the present invention refers to the process of producing a flow medium, which is produced by an industrial device and then transported and distributed through the main network. The flow meter 1 is a flow meter arranged on the main network, and is used to measure the mass or volume flow of the flowing medium produced by the industrial device. In the traditional flow measurement process, the data measured by the flowmeter 1 will be directly transmitted to the industrial control system DCS (distributed measurement control system, used to receive the data from each independent instrument), or through the secondary meter (or flow computer ) to the DCS; after that, the next step is performed by the DCS (such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com