A coal train loading non-continuous accumulative loading system and method

A loading system, non-continuous technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve problems such as loss of tons, low efficiency, and slow loading speed of dustpans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

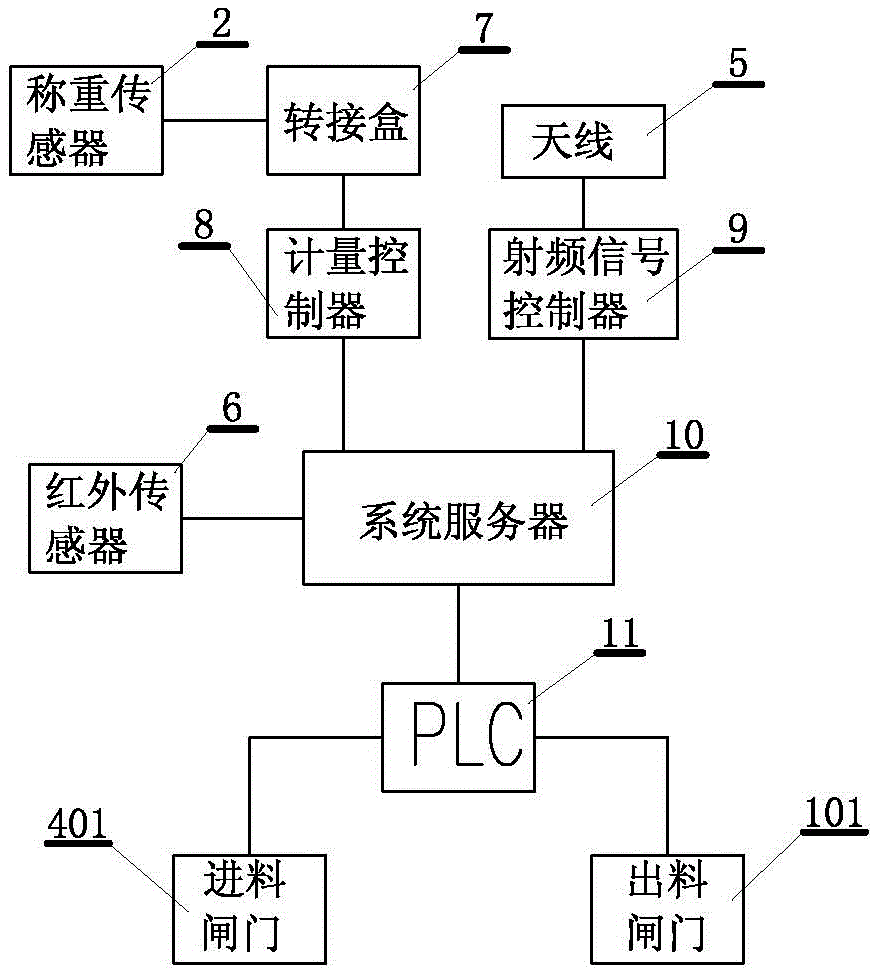

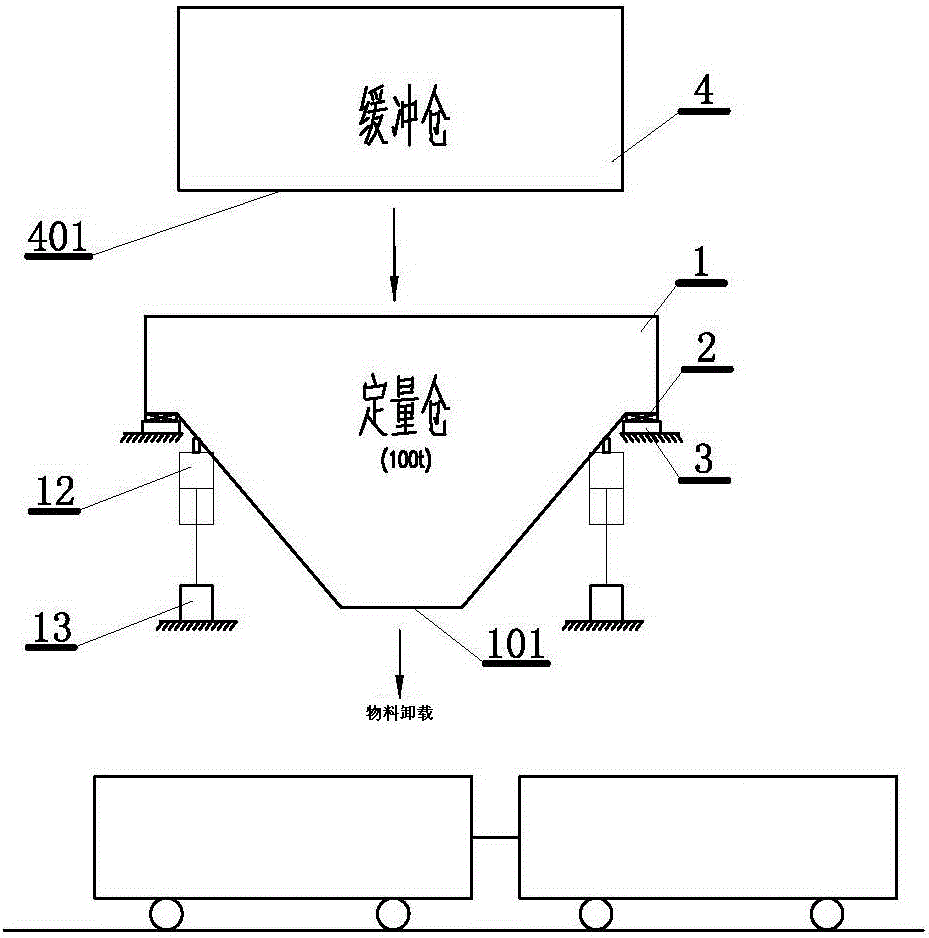

[0026] A non-continuous accumulative loading system for coal train loading, such as figure 1 and figure 2 As shown, it includes a non-continuous accumulative automatic weighing instrument. The non-continuous accumulative automatic weighing instrument is provided with a quantitative warehouse 1 across the train track in the loading area of the train carriage. The quantitative warehouse is supported on four load cells 2, and the four load cells are respectively Set on four supporting bases 3, the quantitative warehouse adopts the mode of upper feeding and lower discharging, and a material buffer bin 4 is arranged on the upper side of the quantitative bin, and the lower end of the buffer bin is aligned with the quantitatively provided feed gate 401. The lower end of the quantitative warehouse is provided with a discharge gate 101; wherein: the system is provided with a radio frequency signal transmitting and receiving antenna 5 on the train track entering the carriage loading ...

Embodiment 2

[0056] A loading method based on the coal train loading non-continuous accumulative loading system described in Embodiment 1, so the content in Embodiment 1 is taken as the content of this embodiment. First, a car information database table is established in the system server, and the load capacity and size data of the cars specified according to the model of the locomotive are entered in the table. When the locomotive enters the loading area at a specified speed, the method includes determining the car loading data The steps and the steps of loading and weighing; wherein:

[0057] The step of determining the loading data of the car is: the system transmits and receives the radio frequency signal arranged on the train track and scans the electronic radio frequency tag data set under the first train car body of the train car. The tag data includes the model of the locomotive. According to the obtained locomotive The model compares the table to determine the load capacity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com