Fin pitch measuring system and measuring method

A measurement system and measurement method technology, applied in the direction of measurement devices, instruments, optical devices, etc., can solve the problems of incompatibility, poor flexibility, and high cost of products with different sizes, and achieve reliable test methods, low cost, and satisfactory The effect of production process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Various embodiments of the invention will be described below with reference to the accompanying drawings, which form a part hereof. It should be understood that although directional terms are used in the present invention, such as "front", "rear", "upper", "lower", "left", "right", "inner", "outer", etc. Various example structural parts and elements of the present invention, but these terms are used herein for convenience of description only, are based on the example orientations shown in the drawings. Since the disclosed embodiments of the present invention may be arranged in different orientations, these directional terms are for illustration only and should not be viewed as limiting. Where possible, the same or similar reference numerals used in the present invention refer to the same components.

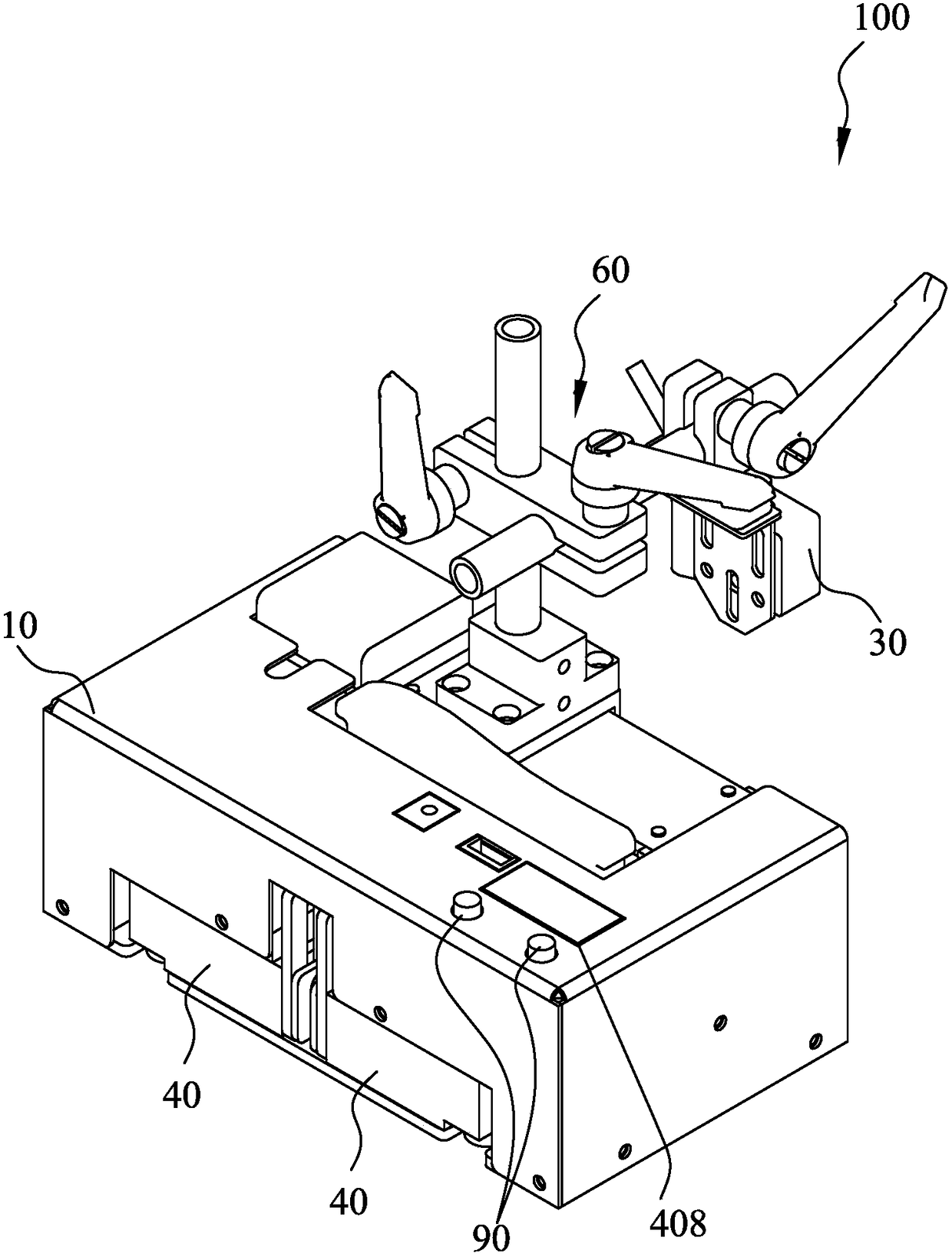

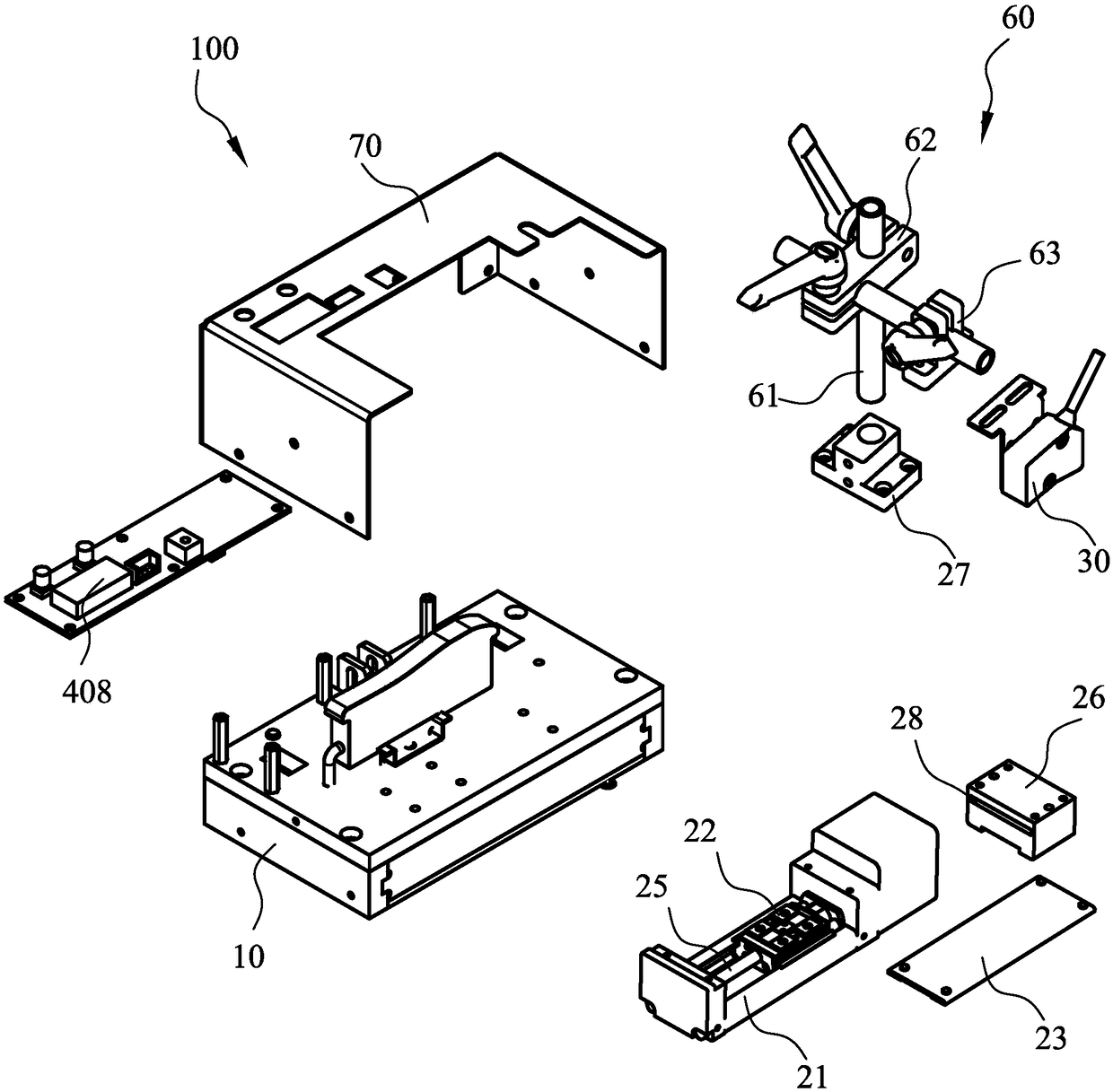

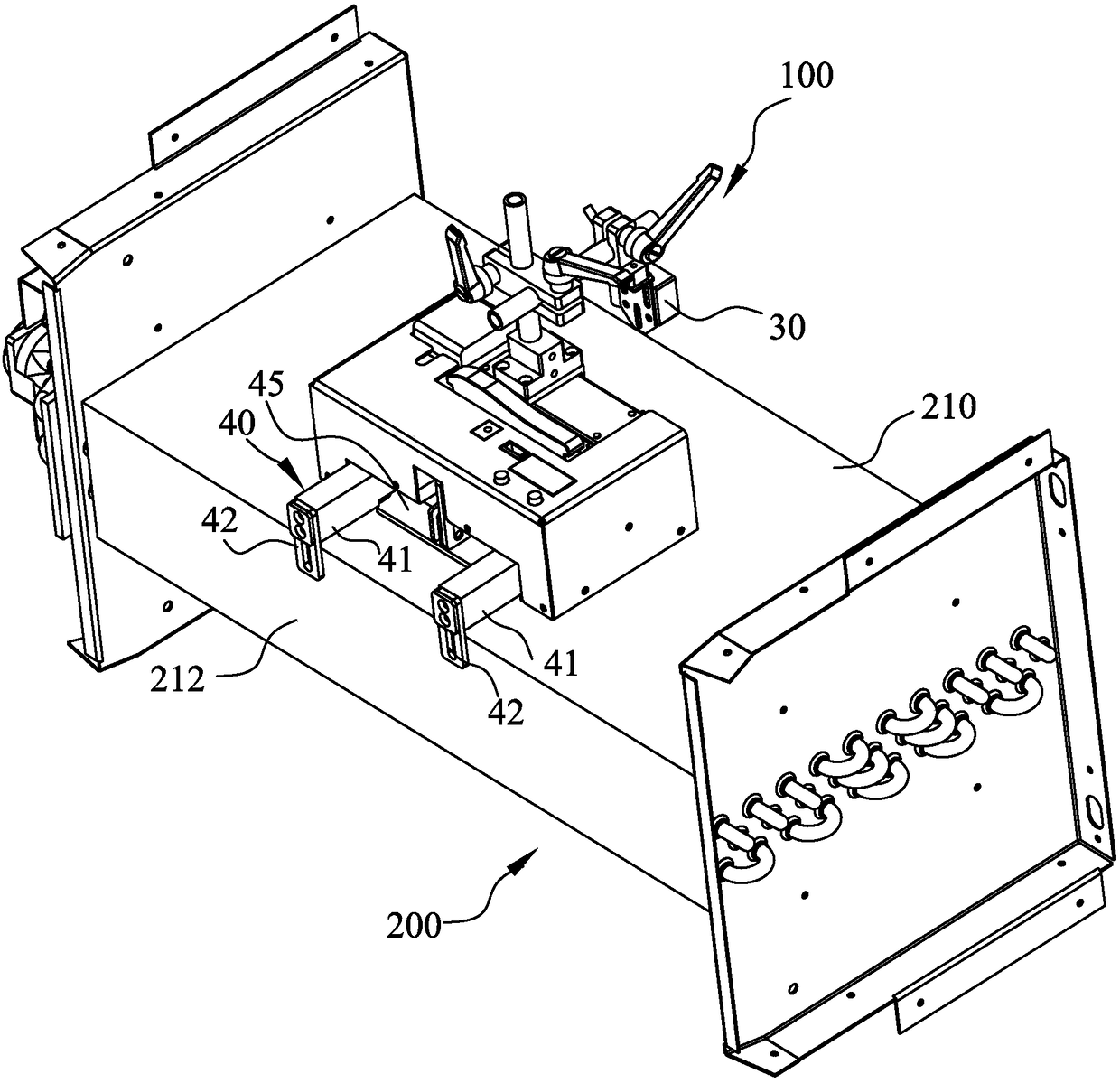

[0024] Figure 1A A perspective view of a fin-to-fin distance measuring system 100 according to the present invention is shown, while Figure 1B is an exploded view of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com