Brake line with good water resistance

A brake cable and waterproof technology, which is applied in the field of brake cables, can solve the problems of not installing waterproof devices at the connection end of the brake cable, and achieve the effects of not easy to break, increasing the force-bearing area, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below by means of the accompanying drawings and examples.

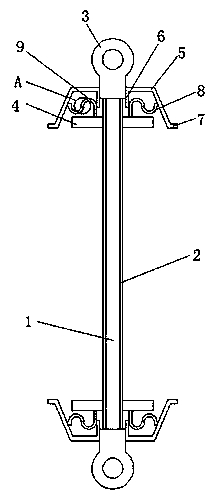

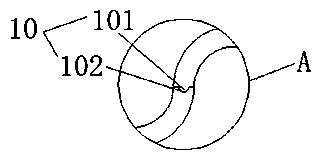

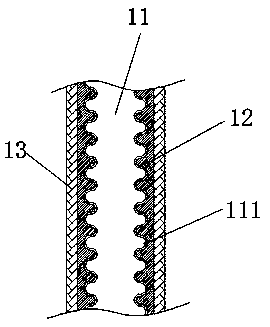

[0029] Such as Figure 1-5 Shown: a brake line with good water resistance, including a brake line body 1, a waterproof cover 2 is set on the outside of the brake line body 1, and a pull ring 3 is set on both ends of the brake line body 1, and the pull ring 3 is used for For the connection with the brake, the pull ring 3 is detachably sleeved on the end of the brake line body 1, and the outside of the end of the pull ring 3 is provided with a forward waterproof cover 5, and the forward waterproof cover 5 connects with the connecting plate 6. The pull ring 3 is welded, the forward waterproof cover 5 is a cylindrical trapezoidal structure, the opening diameter of the waterproof cover 5 is larger than the closing diameter, the opening of the waterproof cover 5 faces the middle of the brake line body 1, and the opening of the forward waterproof cover 5 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com