Centrifugal compressor for butadiene C4 deep processing device

A centrifugal compressor and deep processing technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, machines/engines, etc., can solve the function of the compressor and how to apply it has no reference value, does not involve the structure of the compressor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1100

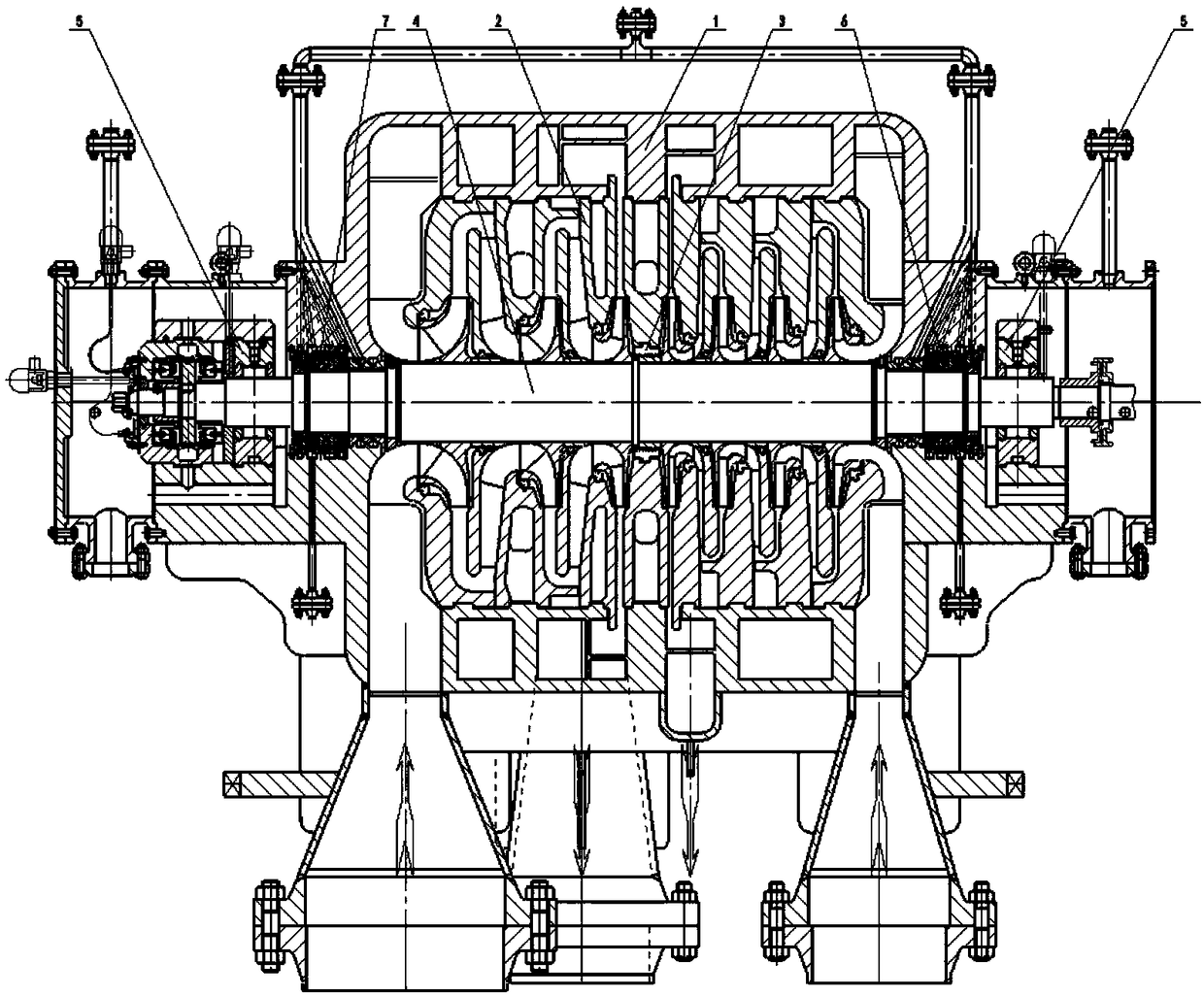

[0025] Example 1 Centrifugal compressor for 1 million tons / year continuous reforming unit

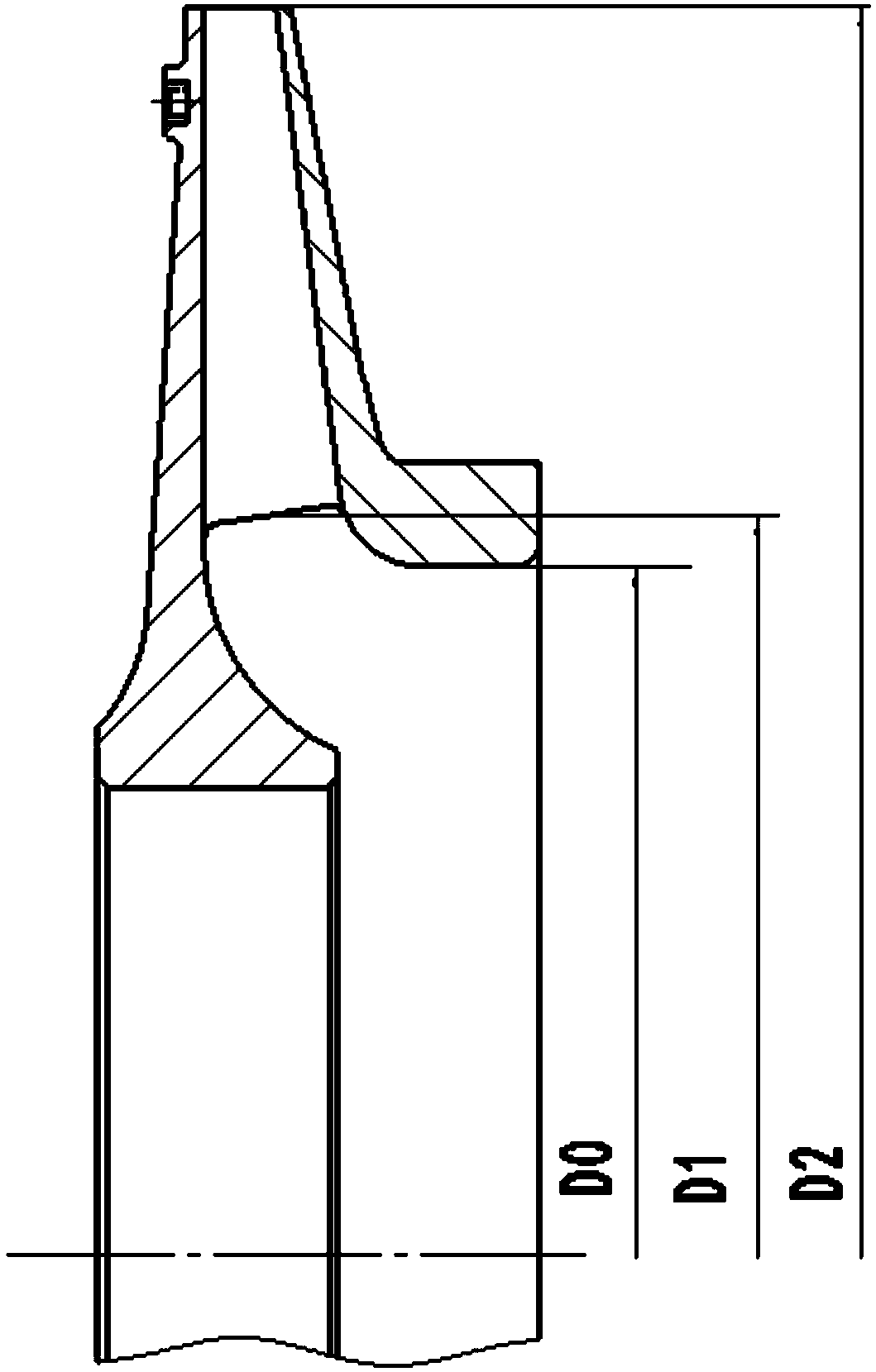

[0026] This embodiment 1 is a horizontally divided two-stage seven-stage centrifugal compressor, the diameter of the impeller is 450 mm, the blade adopts a backward curved structure, the wheel diameter ratio D1 / D2=1.14 (D0 / D2), and the first stage under the rated working condition is more The variable efficiency can reach up to 82.9%, and the variable efficiency of the second stage can reach up to 77.8%.

Embodiment 2

[0027] Example 2 Nitrogen centrifugal compressor for 100,000 tons / year polycarbonate project

[0028] This embodiment 2 is a two-stage eight-stage centrifugal compressor divided horizontally. The diameter of the impeller is 400mm. The variable efficiency can reach up to 74%, and the variable efficiency of the second stage can reach up to 74%.

Embodiment 3

[0029] Example 3 Centrifugal compressor for 100,000 tons / year industrial isooctane plant

[0030] Embodiment 3 is a horizontally divided two-stage eight-stage centrifugal compressor, with an impeller diameter of 600 mm, and its blades adopt a backward curved structure, and the wheel diameter ratio D1 / D2=0.84 (D0 / D2), and the first stage is variable under normal working conditions The highest efficiency can reach 82%, and the second-stage changeable efficiency can reach 76.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com