Method for combined heating and power of aluminum oxide plant

A technology for combined heat and power supply and aluminum plants, which is applied in the directions of combined combustion mitigation, steam engine installations, gas turbine installations, etc., can solve the problems of increasing the unit production cost of alumina, difficult to take into account both heat and power, and balance supply of heat and power, and achieves a small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

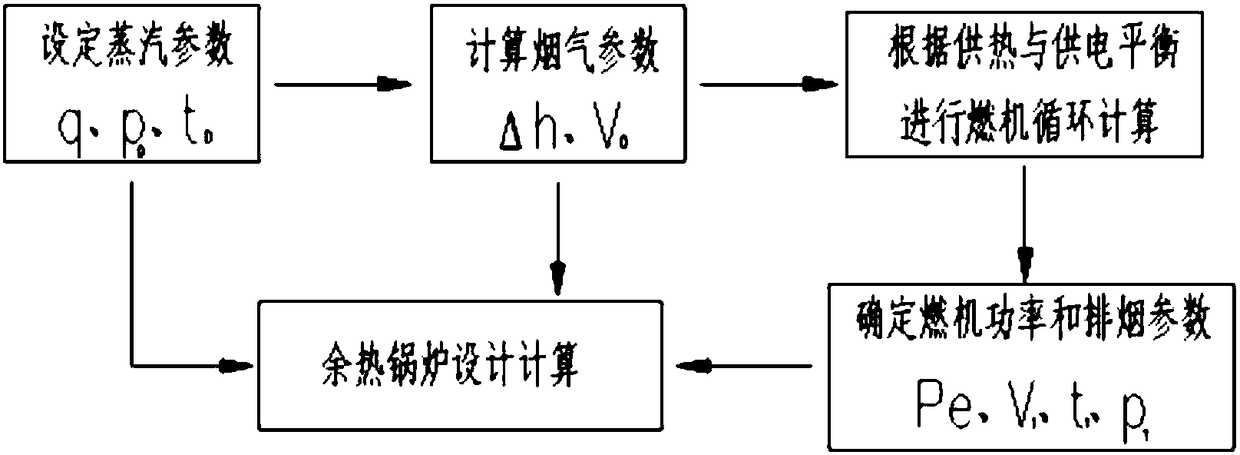

[0020] Such as figure 1 As shown, according to the requirements of the alumina high-pressure dissolution system for high-pressure steam, set the supply steam parameters, mainly including the flow rate q 0 , pressure p 0 and temperature t 0 , on the basis of setting the steam parameters, calculate and set the appropriate flue gas enthalpy drop Δh and flue gas flow rate V 0 . According to the heat supply and power supply balance, the gas turbine cycle calculation is carried out to determine the gas turbine power Pe and smoke exhaust volume V 1 , exhaust gas temperature t 1 , exhaust gas pressure p 1 . According to the basic conditions such as setting steam parameters, calculating flue gas parameters, and gas turbine exhaust parameters, the design calculation and type selection of waste heat boilers are carried out.

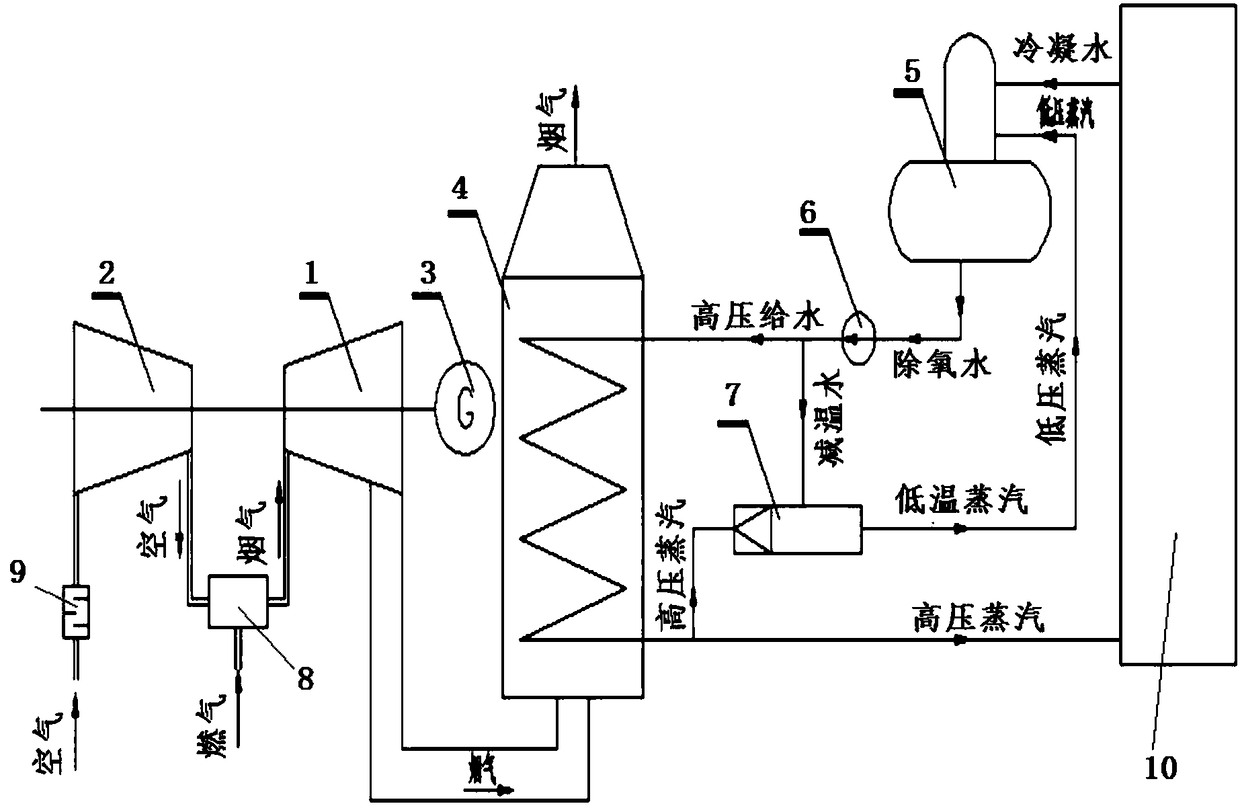

[0021] Such as figure 2 As shown, the gas turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com