SteeL-UHPC combination beam for cabLe-stayed bridge and construction method

A technology of cable-stayed bridges and composite beams, applied in the field of bridge engineering, can solve problems such as unfavorable applications, mechanical properties and crack resistance properties that cannot meet the requirements, and achieve the effects of saving engineering costs, superior crack resistance performance, and ensuring connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

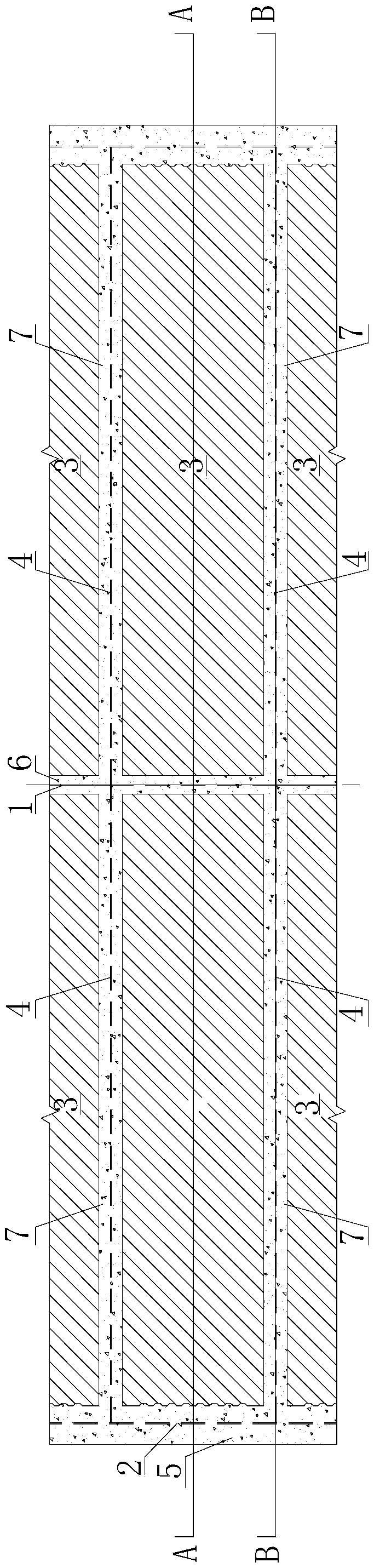

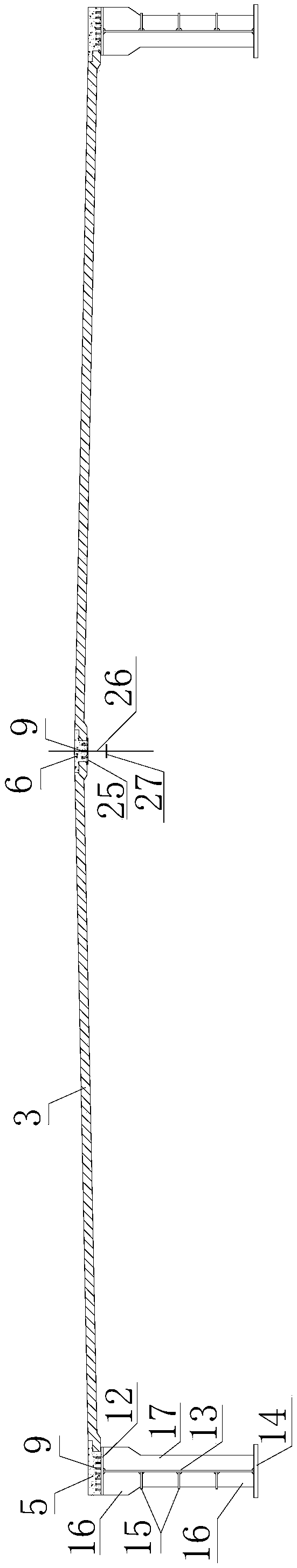

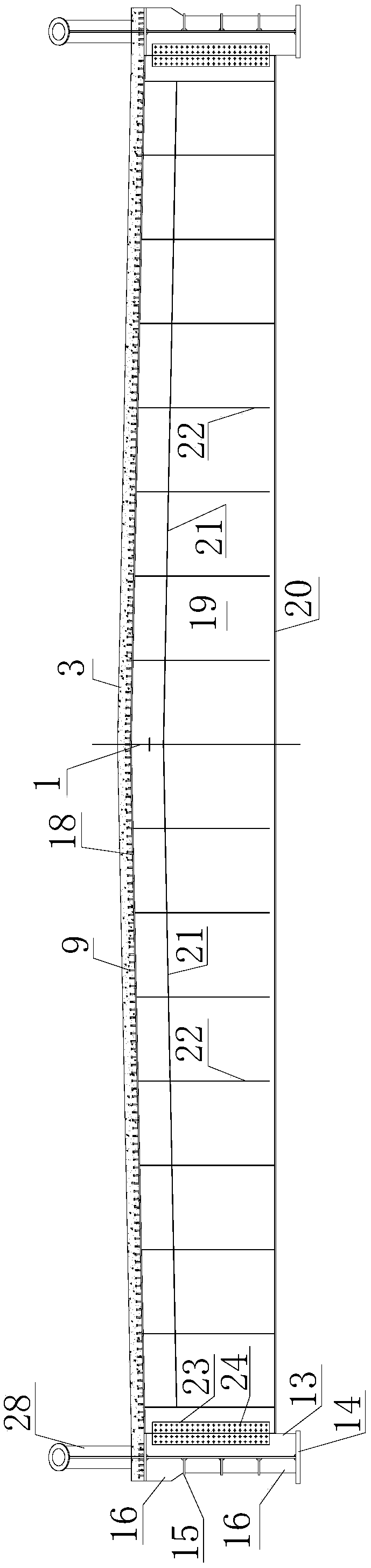

[0035] Figure 1 to Figure 7 An embodiment of the present invention is shown. In the steel-UHPC composite girder used for a cable-stayed bridge in this embodiment, there are two main longitudinal girders 2 arranged in parallel on both sides. There is a pouring belt 5; the middle longitudinal beam 1 has one, which is arranged in the middle of the two main longitudinal beams 2, and divides the bridge deck into two equal parts. The middle longitudinal beam 1 is the middle longitudinal cast-in-place belt 6; Pouring tape7. Set a 10mm thick rubber pad 11 on the top surface of the rectangular lattice surrounded by the main longitudinal beam 2, the intermediate longitudinal beam 1, and the cross beam 4, on which the UHPC prefabricated slab 3 rests, and is connected to the steel beam lattice by various cast-in-place belts and shear members 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com