Seepage-enhancing and blocking-removing liquid for uranium mines as well as using method and application thereof

A plugging and uranium mining technology, which is applied in the field of plugging removal in uranium mines, can solve the problems of short plugging removal effective time and poor plugging removal effect, and achieve the effect of enhancing plugging removal effect, prolonging the plugging removal validity period, and expanding the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

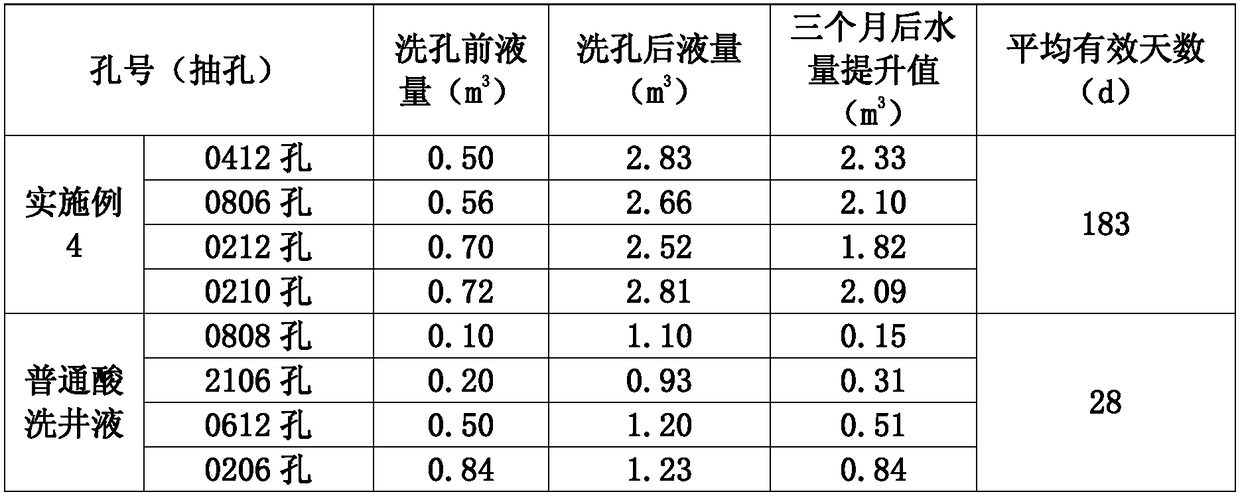

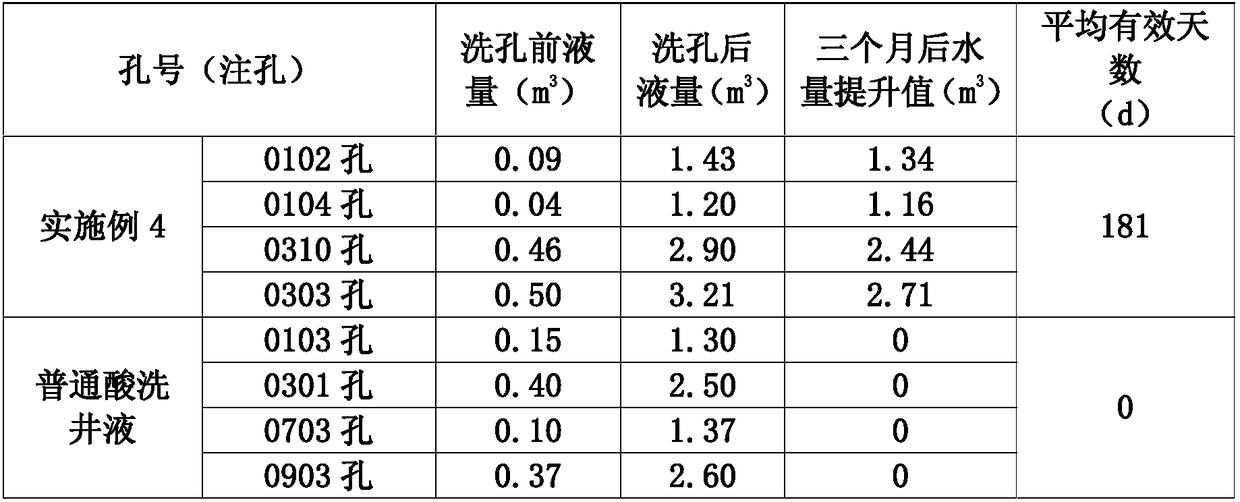

Examples

Embodiment 1

[0015] Example 1: Permeability-increasing and plugging-removing fluid for uranium mines, the components include comprehensive plugging-removing agent I, comprehensive plugging-removing agent II and anti-swelling displacement fluid, the volumes of comprehensive plugging-removing agent I, comprehensive plugging-removing agent II and anti-swelling displacement fluid The ratio is 2 to 13:1.5 to 7:3 to 4; the raw materials of comprehensive plugging remover I include hydrochloric acid and active acid; the raw materials of comprehensive plugging remover II include deep plugging removal acid, acidification corrosion inhibitor and iron ion stabilizer; The raw materials of the anti-expansion replacement liquid include monomolecular membrane active agent and potassium chloride.

[0016] In the permeability-increasing and plugging-removing fluid for uranium mines described in the present invention, the raw materials of each component have good compatibility, and the compatibility of each c...

Embodiment 2

[0022] Example 2: The components include comprehensive plugging removal agent I, comprehensive plugging removal agent II and anti-swelling displacement fluid, and the volume ratio of comprehensive plugging removal agent I, comprehensive plugging removal agent II and anti-swelling displacement fluid is 2 or 13:1.5 or 7 : 3 or 4; the raw materials of comprehensive plugging removal agent I include hydrochloric acid and active acid; the raw materials of comprehensive plugging removal agent II include deep plugging removal acid, acidification corrosion inhibitor and iron ion stabilizer; the raw materials of anti-swelling replacement fluid include single-molecule membrane active agent and potassium chloride.

Embodiment 3

[0023] Example 3: As an optimization of the above examples, the plugging removal solution for uranium mines includes comprehensive plugging removal agent I, comprehensive plugging removal agent II and anti-swelling replacement fluid; the raw materials of comprehensive plugging removal agent I are calculated by mass percentage Including 8% to 10% of hydrochloric acid, 1.5% to 5% of active acid and the balance of water; the raw materials of comprehensive plugging remover II include 2% to 5% of deep plugging removal acid and 1% to 5% of acidification corrosion inhibitor in terms of mass percentage. 2%, iron ion stabilizer 1% to 2% and the water of balance; amount of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com