Method for extracting pigment by using plant ash method

A plant ash and pigment technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of low extraction efficiency and long pigment extraction time, and achieve the effect of simple operation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

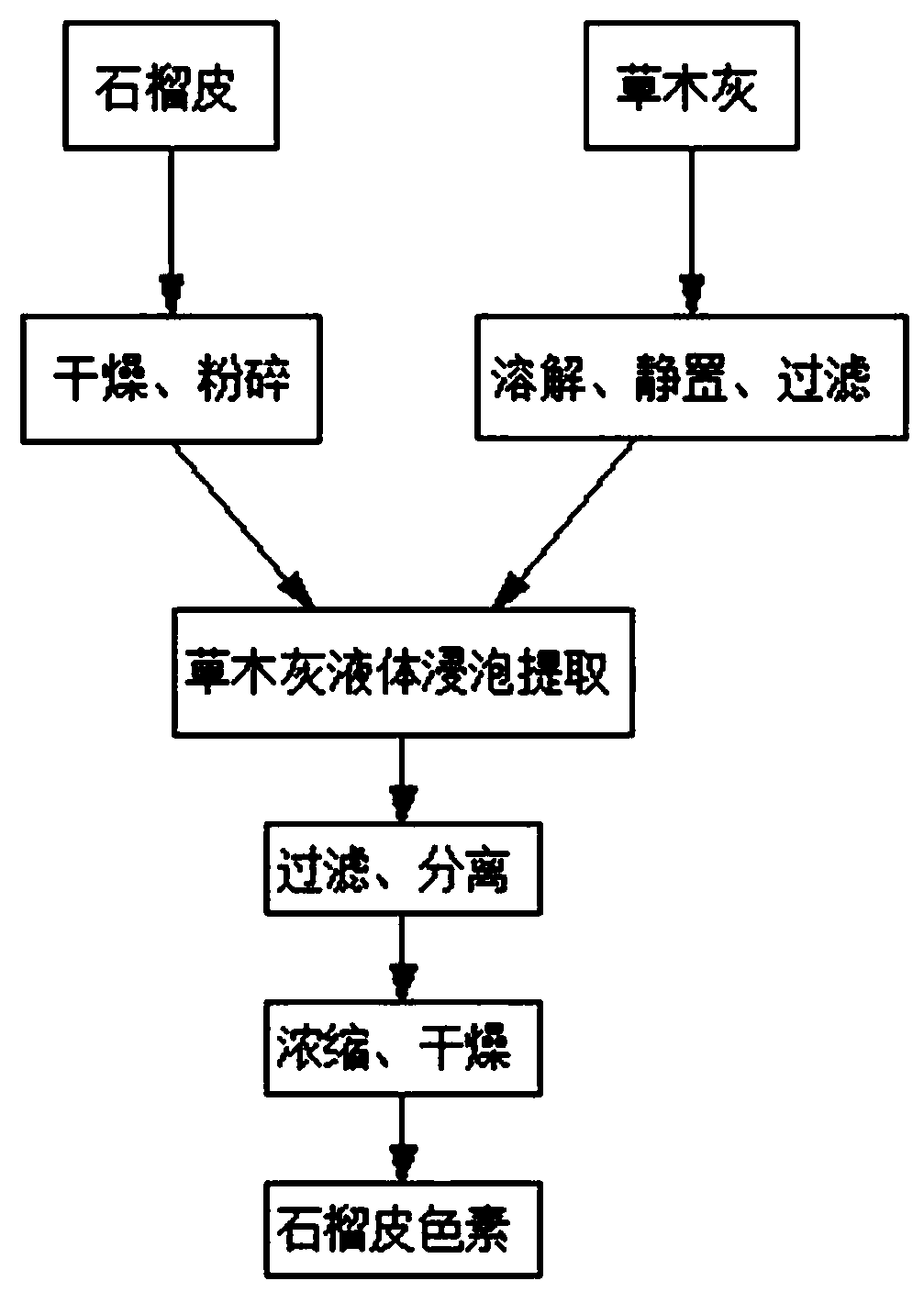

Method used

Image

Examples

Embodiment 1

[0024] The application discloses a method for extracting pomegranate peel pigment by plant ash method, comprising the following steps:

[0025] Take 2g of pomegranate peel, after cleaning, put it in an oven and dry it at 55-65°C until the moisture content is less than 15%, cool it at room temperature, pass through a 20-mesh sieve after crushing, and store the pomegranate peel powder in a dry environment for later use;

[0026] Weigh 0.6g of plant ash and place it in a container, add 100-400ml of deionized water into the container, put the container in a water bath constant temperature oscillator and heat for 20-45min, set the temperature to 60-90°C, and set the oscillation frequency to 80r / min , the prepared plant ash solution was cooled to room temperature, allowed to stand for 10-15 minutes, and undissolved impurities were filtered out;

[0027] Add 2g of pomegranate peel powder into the container of the plant ash solution prepared above, place the container in a constant te...

Embodiment 2

[0031] The application discloses a method for extracting pomegranate peel pigment by plant ash method, comprising the following steps:

[0032] Take 2g of pomegranate peel, after cleaning, put it in an oven and dry it at 55-65°C until the moisture content is less than 15%, cool it at room temperature, pass through a 20-mesh sieve after crushing, and store the pomegranate peel powder in a dry environment for later use;

[0033] Weigh 0.12g of plant ash and place it in a container, add 200ml of deionized water into the container, put the container in a water bath constant temperature oscillator and heat for 20-45min, set the temperature at 60-90°C, and set the oscillation frequency at 80r / min. The resulting plant ash solution was cooled to room temperature, allowed to stand for 10-15 minutes, and undissolved impurities were filtered out;

[0034] Add 2g of pomegranate peel powder to the container of plant ash solution prepared above and the container of alkaline aqueous solution...

Embodiment 3

[0037] Embodiment 3 is different from the method for extracting pomegranate peel pigment in Example 1 in that embodiment 3 adopts an ultrasonic-assisted method when extracting pomegranate peel pigment, specifically as follows, a method for extracting pigment by plant ash method disclosed in Example 3, including Follow the steps below:

[0038] Take 2g of pomegranate peel, after cleaning, put it in an oven and dry it at 55-65°C until the moisture content is less than 15%, cool it at room temperature, pass through a 20-mesh sieve after crushing, and store the pomegranate peel powder in a dry environment for later use;

[0039] Weigh 0.6g of plant ash and place it in a container, add 100-400ml of deionized water into the container, put the container in a water bath constant temperature oscillator and heat for 20-45min, set the temperature to 60-90°C, and set the oscillation frequency to 80r / min , the prepared plant ash solution was cooled to room temperature, allowed to stand for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com