Method for improving clarity of resorcinol

A technology of resorcinol and clarity, applied in the field of medicinal chemistry, can solve problems such as not being able to be used in medicine, not meeting GMP requirements, etc., and achieve the effect of solving the problem of clarity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

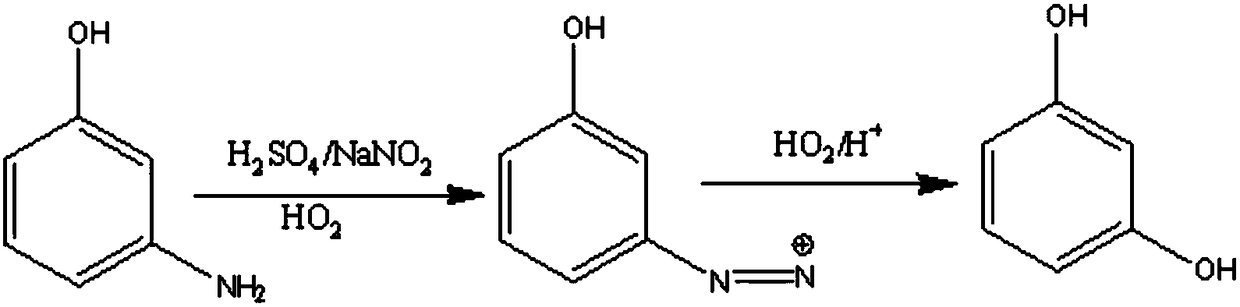

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of method improving resorcinol clarity,

[0030] Add 75g of commercially available resorcinol (turbidity 33) into 250g of saturated aqueous sodium chloride solution, stir until the resorcinol is dissolved; then add 150g of methyl tert-butyl ether for 2 extractions, and combine the organic phases , add 2g of activated carbon for decolorization, anhydrous sodium sulfate (30g) for dehydration, stir for 1h, filter, concentrate the filtrate at 25°C, vacuum degree ≤ -0.09MPa until no liquid drips out, add 100g of dichloromethane for beating for 1 hour, filter , the solid (filter cake obtained by filtration) was dried to constant weight at 30-40° C. under vacuum (vacuum degree ≤-0.09 MPa) to obtain 50 g of resorcinol (yield 66.7%), and the measured turbidity was 1.3.

Embodiment 2

[0031] Embodiment 2, a kind of method improving resorcinol clarity,

[0032] Add 50g of commercially available resorcinol (turbidity 33) into 150g of saturated aqueous sodium chloride solution, stir until the resorcinol is dissolved; then add 150g of ethyl acetate x 2 extractions, combine the organic phase liquid, add 2g Decolorize with activated carbon, dehydrate with 30g of anhydrous sodium sulfate, stir for 1h, filter, concentrate the filtrate at 25°C, vacuum degree ≤ -0.09MPa until no liquid drips out, add 80g of toluene for beating for 1 hour, filter, solid at 30-40°C Vacuum drying to constant weight yielded 35 g of resorcinol (70% yield), and the measured turbidity was 2.2.

Embodiment 3

[0033] Embodiment 3, a kind of method that improves resorcinol clarity,

[0034] 75 g of resorcinol (turbidity 16) obtained by synthesis was processed according to the method described in Example 1 to obtain 50 g of resorcinol (yield 66.7%) and turbidity 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com