Storage battery plant sewage purification device

A sewage purification and battery factory technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve environmental and social hazards and other problems, and achieve the effect of improving purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

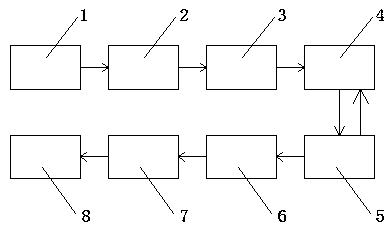

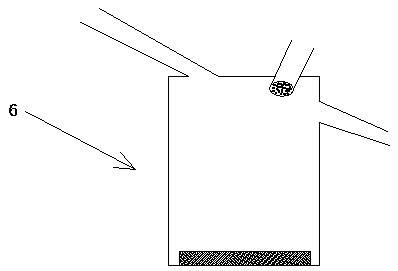

[0023] see Figure 1-7 , a battery plant sewage purification equipment, including a water inlet pipe, also includes sequentially connected coarse filter tank 1, fine filter tank 2, anaerobic tank 3, anoxic tank 4, aerobic tank 5, sedimentation tank 6, membrane tank 7 One end of the inlet pipe is connected to the sewage pool, the other end is connected to the coarse filter pool 1, the aerobic pool 5 is connected to the anoxic pool 4 through the return pipe, the bottom of the sedimentation tank 6 is provided with a magnet, and the top of the sedimentation tank 6 is provided with an iron Chip spout, fine filter tank 2 and anaerobic tank 3 are connected by fine filter pipeline;

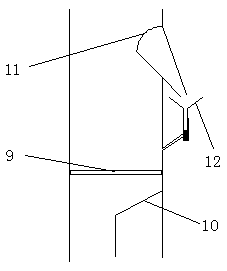

[0024] The fine filter tank 2 is a vertical filter pipe, and the filter screen 9 is connected with the rotation in the pipe. The upper end of the filter screen 9 is connected to the backwashing device, and the lower side is connected to the sewage pipe, and an electric rotating baffle plate 10 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com